Excavated Material

Excavated Material

The construction of Crossrail resulted in the generation of over 7 million tonnes of excavated material, of which over 98% was beneficially reused. Crossrail adopted a client-led approach to the reuse of the material (whereby the destination sites and means of transportation were specified to contractors by Crossrail) together with flexibility to allow some of the individual contracts to make their own arrangements for beneficial reuse as appropriate. The benefits of adopting a client-led approach were that it allowed a significant proportion of the material to be used to create a landmark new nature conservation project at Wallasea Island, it reduced the programme risk associated with a potential lack of suitable disposal sites during the main tunnelling and excavation works and it also allowed the development of infrastructure to allow transportation by water and the early allocation of rail paths which together contributed to 80% (per tonne km) of the excavated material being transported by rail or water.

An Excavated Material learning legacy paper describes the approach followed by Crossrail to reuse the excavated material from the project, identifying the main stages of the process, the key activities undertaken by both the client and contractor and the lessons learned from implementation. It will be of use to clients of major infrastructure projects who are looking to adopt a similar approach to the reuse of excavated material. The lessons learned at construction sites that were implementing the Crossrail requirements will also be of use to any project or contractor who is disposing of excavated material. A paper on the Transport and Beneficial Re-use of Crossrail Excavated Material deals with the nature of the Crossrail excavated material and associated transportation issues and the permissions framework that allows the excavated material to be deposited at Wallasea Island.

Designing Out Waste

Using resources developed by WRAP, Crossrail undertook a series of designing out waste workshops with its designers and contractors to identify opportunities for reducing waste through good design. The designing out waste learning legacy provides a summary of the process adopted by Crossrail.

Recycled Content in Construction

Crossrail used WRAP’s Netwaste Tool for calculation of Recycled Content using the standard UK industry metric of % recycled content by value developed by WRAP in 2006/7. The tool was used to enter Bill of Quantity information (quantities and costs) and calculate the default recycled content. The quick wins function in the tool was then used to identify opportunities to increase recycled content. Completion of this exercise for Crossrail has identified the key opportunities and these will be shared in a learning legacy paper on recycled content. The WRAP Tool will not be available to future projects so the learning legacy will identify the key materials identified using the tool and also provides a spreadsheet that can be used by future projects to undertake similar calculations.

Water Use

Crossrail required construction contracts to monitor the volume of water used during construction, for example over 275,000 cubic metres of water was used during 2015. The most water intensive construction processes are tunnelling using tunnel boring machines and sprayed concrete lining. Water data collected from Crossrail construction sites was collated and a learning legacy paper outlining the best practice use of water on Crossrail is available that could be a useful resource for future research and benchmarking.

| Summary |

Publication date |

Document Type |

Topic area: Resource Management Crossrail Ltd (CRL) required its tier 1 contractors to record water consumption on a periodic basis. A summary dataset has been made available on water consumption across the Crossrail Central Section Contracts. This data could be useful to future projects as a basic comparison to construction projects with similaritie...

|

09/07/2018 |

Dataset |

Topic area: Resource Management Crossrail Ltd (CRL) required its tier 1 contractors to implement best practice for recycling as much water collected on site as practicable for reuse during construction and to minimise water use in site accommodation. This paper presents case studies that demonstrate the best practice measures that were implemented to...

|

13/03/2018 |

Micro-report |

Topic area: Resource Management Crossrail used WRAP’s Net Waste tool to identify the best opportunities to increase the recycled content of material used for construction.

This micro report details how it was used on the Crossrail project, what lessons were learned and what outcomes were achieved. It gives an insight into the value to projects of u...

|

19/09/2017 |

Micro-report |

Topic area: Resource Management The construction of the Crossrail project resulted in the generation of over 7 million tonnes of excavated material, of which over 98% was beneficially reused. Crossrail adopted a client-led approach to the reuse of the material (whereby some of the destination sites and means of transportation were specified to cont...

|

31/03/2017 |

Micro-report |

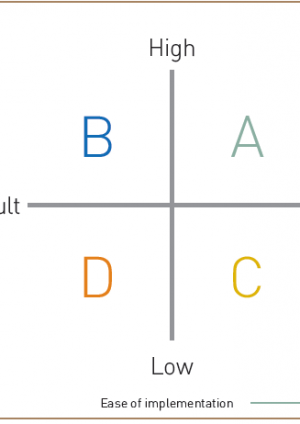

Topic area: Resource Management Crossrail follows the Waste Resources Action Programme (WRAP) supported Designing Out Waste process, identifying opportunities in a collaborative work shop including client, designer & contractor. Once opportunities are identified they are placed on an opportunities matrix. This allows for higher impact and mor...

|

26/02/2016 |

Good Practice Document |

Topic area: Resource Management This paper is a version of a paper presented at a conference held by the Italian Tunnelling Society in Verona in May 2014[1]. As such it is largely an introduction to this topic with only limited technical content.

The paper has two parts, the first deals with the nature of the Crossrail excavated material and associat...

|

07/09/2015 |

Technical Paper |

Topic area: Logistics Paddington station has been used as an example to detail the controlled manner in which HGV lorry movements were managed during construction over a five year period. This paper provides a summary of the site construction, the HGV movement logged, and how that movement is linked to construction at the site. It also show...

|

09/07/2018 |

Micro-report |

Topic area: Logistics Logistics in construction often focuses on the challenges within the site boundary, leaving those outside the gate to be addressed when dictated by the programme. But early in the projects development Crossrail identified this as an area which it wanted to be proactively managed so that impacts outside the hoarding wer...

|

14/03/2017 |

Journal Publication |

Topic area: Environment Webinars This is the fourth in a series of Crossrail Learning Legacy webinars focused on the Environment Theme, in conjunction with our partners CIRIA and IEMA.

The construction of Crossrail resulted in the generation of over 7 million tonnes of excavated material, of which over 98% was beneficially reused. Crossrail adopted a ...

|

02/02/2017 |

Video |

Topic area: Environmental Requirements A contaminated land assessment was carried out as part of the Crossrail Environmental Impact Assessment. The results were reported in the Crossrail Environmental Statement submitted with the hybrid Bill. A Contaminated Land Specialist Technical Report was produced at the same time to provide further information about t...

|

26/02/2016 |

Good Practice Document |

Topic area: Environmental Requirements The Water Resources chapter of the Construction Code required Crossrail to prepare a strategy for handling water resources issues in consultation with the Environment Agency (EA) that would be based on accepted industry practice. It also required that the process for agreeing the strategy include liaison and consultati...

|

26/02/2016 |

Good Practice Document |

Excavated Material

Excavated Material