Optimisation of door operating performance in Crossrail stations

Document

type: Technical Paper

Author:

Wing Fung PhD MSc BSc(Eng) CEng MCIBSE

Publication

Date: 02/12/2021

-

Abstract

This paper consolidates the technical assurance requirements and related dependencies for door opening forces and related issues in Crossrail stations. The dependencies include alignment with the way the station is operated to support PRM movement and the implementation of the retrofit work to alleviate high door forces (speed reduction of tunnel ventilation fans, delay operation of the staircase pressurisation system etc.)

-

Read the full document

1 Introduction

Specific door opening forces and related issues like suitability for use under static and dynamic operating environments, occurrence of slamming, ability of door lock to release and re-latch smoothly and suitability of door for use by people with restricted mobility (PRM) etc. were stipulated in the Works Information and Building Regulations. These requirements are mainly associated with the operation of doors in the evacuation and intervention routes, protected lobbies and staff rooms. There are also specific technical requirements to address doorways intended to be used by PRM, both for the public and staff, assisted or un-assisted. The operating performance of many of these doors should not be impaired by the effects of air pressure difference due to the operation of the smoke control systems in the station during an emergency event.

Door tests and integration tests for station rooms at the testing and commissioning stage indicated that in many cases the stipulated door operating requirements had not been met, either because the limitation of the door/ door gear design, or in situations when the doors are under high pressure differences when emergency ventilation systems are in operation. The latter phenomenon is more apparent in doorways at the platform level of the station.

Some of the common commissioning problems are:

- Door closers have to be ‘tightened’ to prevent slamming upon closing when emergency ventilation systems are in operation. In doing so, the maximum acceptable door opening force requirement cannot be met.

- High door opening force when emergency ventilation systems are in operation.

- Failure to re-latch because of heavy door, door lock and/ or door closer settings.

- The provision of door closer to maintain fire compartmentation has led to high door opening force.

As such, Crossrail has put in place a structured assurance framework to manage door performance issues encountered during commissioning. This entails compilation of the results of door settings and operating characteristics, identification of anomalies, carryout door force optimisation and close out of nonconformance noted.

This paper highlights the pertinent issues and lessons learnt in optimising door operating performance.

2 Assurance Requirements on Door Opening Forces and related issues

There are two main categories of doors in Crossrail stations:

- Doors along the passageways for evacuation and fire brigade intervention. These doors are as defined in BS 9999: Section 32.1.6.1. Many of these are doors to be used by PRM. There are also doors held open during normal use and close automatically in an emergence. For the latter doors, maximum opening force requirement will not apply as the delay release time has been calculated and suitable to allow PRM to pass through the door to a place of safety before closure.

- Access doors to the station accommodations. Many of these doors will be used for PRM movement, such as those leading to station operation rooms, staff mess rooms, changing rooms, disable toilets etc. It is recognised that there are rooms in the station, like equipment rooms that are not appropriate or suitable for PRM use. This is because an HSE Risk Assessment identifies it would not be safe for a PRM to access the space beyond the door or (possibly) to access the space unassisted and/or there is no step free level access route (e.g. area accessed by ‘cat ladder’).

With the exception of equipment room doors, the acceptance criteria adopted for the station doors are:

- Door opening force not to exceed 100N (30N for doors intended for PRM use).

- Latch release force not to exceed 70N.

- Push bar/ panic bar force (if fitted) not to exceed 80N.

- Door re-latch upon closing if door closer is fitted.

- No slamming upon closing.

The above criteria will apply for all working environments including static and dynamic conditions when smoke control ventilation fans are in operation. The acceptance criteria are primarily derived from BS 9999: Section 27.5, BS 9992 and BS8300: 2010 Section 6.5.6.

Clarification was sought from stakeholders as to the level of assistance that would be offered by station staff to PRM both during a station evacuation and for staff access to accommodation. PRM will be assisted through the evacuation doors by staff members carrying out their “sweep” of an incident station. On the basis that the risk assessment evidences on the approach can reasonably be considered ALARP, Crossrail have acted in accordance with the recommendations set out in the assurance documents to facilitate assisted emergency evacuation to a place of relative safety for public and staff PRM.

3 Door operation performance reporting and optimisation

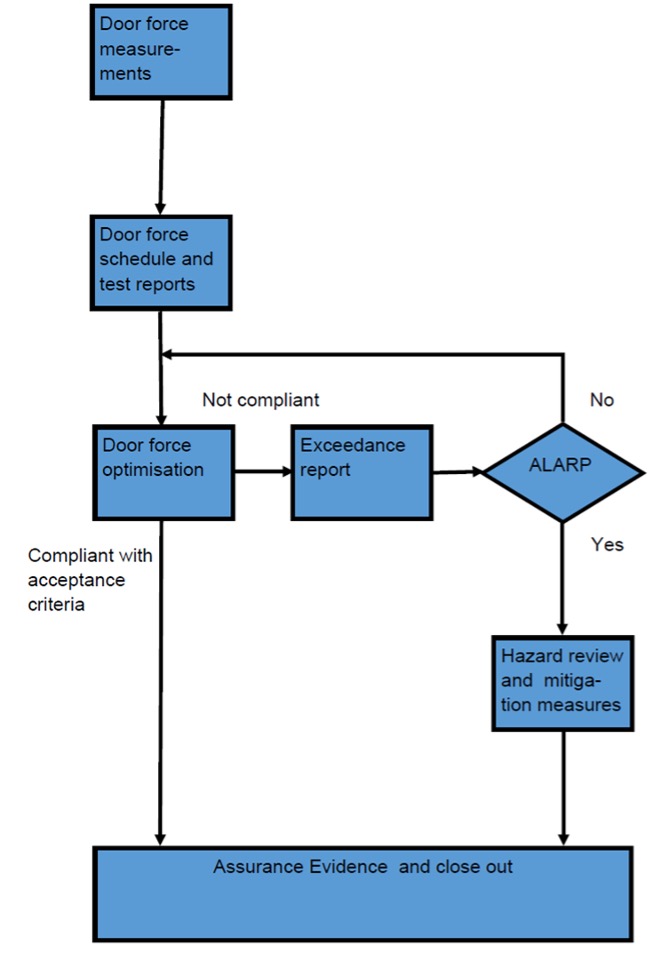

The assurance process adopted to manage door force and related requirements is illustrated in the process flow diagram in Figure 1 below:

Figure 1. Door operation performance reporting and optimisation

Upon completion of the commissioning of the door system, the following assurance evidence shall be presented to the Crossrail assurance team for review and acceptance:

- Door schedule and related door force test reports (e.g. for staircase pressurisation and air release system).

- Record of optimisation of door forces and related requirements (e.g. slamming and door lock latching). It is recognised the acceptance requirement can be conflicting in nature e.g. minimise door opening door forces in door closer setting may lead to occurrence of slamming; door gear settings under static condition does not work satisfactory under dynamic condition when station smoke control system is in operation.

- Justification that the deviations from the acceptance criteria in the Exceedance Assessment Report are ALARP. The ‘Exceedances Report’ should contain the following:

- Check with the scope of concession against the standard and accepting the risk of challenge under the Equality Act.

- Provide justification for the exceedances and they are within the Crossrail maximum tolerance.

- Include specific concessions where the test results are not complying with the acceptance criteria.

- Include the results of hazard assessments as appropriate and demonstrate that the door opening forces and related requirements at the handover state is ALARP.

For doors fitted with a hold-open device, the automatic fire detection and fire alarm system will actuate an automatic release mechanism when required after a time delay. The delay timer settings are commissioned at two minutes. It is anticipated that the final time delays will be determined after handover in accordance with the result of the dry evacuation runs.

4 Door force optimisation- General practice

It is essential that, in the optimisation exercise, due consideration has been made on the following possible options before the case is considered ALARP:

- Omission of the door closer- For PRM use doors, the Contractor shall consult with their fire engineer to confirm the need for door closers to maintain fire compartmentation in accordance with the station fire strategy report. Door closers not critical to the station functional performance or fire safety may if appropriate be removed if the door forces are in exceedance of the performance requirement.

- Provision of an electro-magnetic hold open with door release after a time delay function. The duration of time delay will be established by assessing how long it will take for a PRM to pass beyond the doorway in an emergency situation.

- The use of a free swing closer- The CAM-motion door closers allow the door to be light to open while retaining its closing power.

- Optimising closer type and performance efficiency- The efficiency of the closer is an important factor to the door force. All fire rated doors are required to be self-closing and so fitted with a controlled closing device (closer) to ensure the door is in the correct position to provide the fire rating as required. The closer operating force must be overcome in order to open the door. Closers with higher efficiency provide less resistance and as a result they require less force to open. The set-up of the closer is also very important; a high efficiency closer set incorrectly will still exceed the maximum opening force. This is exacerbated in lower efficiency closers. Due to their low closing moments door closers size 1 and 2, without adjustable closing force, are NOT considered suitable for use on fire/smoke door assemblies. Door closers with an adjustable closing force shall be capable of adjustment at least to power size 3. For such closers the installation instructions should include precise instructions to the installer to ensure that the door closer power is adjusted on site to size 3 or better, to overcome resistance of any seals or latches fitted. The Contractor is to check and confirm all closers have been correctly specified, installed and set up for the door.

- Providing hinges and mortice latch/ lock of least resistance – Door hardware of good quality and with low friction design will assist in reducing the effect on manual operating and opening forces.

- Providing appropriate seal types and orientation to minimise the resistance- Smoke, acoustic and privacy seals around the perimeter of the door affect the opening force due to the frictional resistance they produce. Brush or blade type seals, which are typically fitted in swipe/wipe mode against cold smoke and acoustic penetration provide the biggest resistance and it is therefore unlikely that smoke seal or certain acoustic door assemblies will maintain the minimum opening force identified in Document M. Compression seals that are generally fitted on the face of the doorstop produce less friction than seals in swipe/wipe mode and therefore are subject to lower opening forces.

- Confirming correct installation – Poor installation workmanship will contribute to high opening force. Doors are to be square and plumb with the correct gaps between door and frame around the jambs and head will provide less resistance than a door installed out of tolerance.

- Ensure the appropriate acoustic doorsets are utilised.- Approved document E sets out the requirements for the acoustic requirements of a building and in order to do this the door assembly may require seals to be provided at the jambs, head, and in the case of pairs, the meeting stiles. Door assemblies with lower acoustic performance and fewer seals tend to have lower opening forces meet the requirement. Higher acoustic performance requires better sealing which results in increased resistance to opening and consequently results in higher opening forces. Acoustic door assemblies will generally have some form of threshold sealing mechanism and these again can have an impact on the opening forces.

5 Door force optimisation- Correct door closer setting to balance door opening force re-latching and slamming

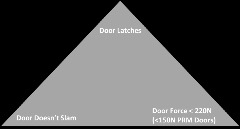

Numerous iterations have to be made to find the most appropriate door closer setting to minimise the slamming experienced while the resulting door opening force will not be excessively high and that the door will re-latch upon closing. This can be summarised under Figure 2 where only two of the three conditions can be achieved at any one time:

Figure 2. Interactions among door opening force, slamming and re-latching

6 Door force optimisation- Optimise tunnel ventilation system fan speed

TVS operating speeds are optimised to help reduce the door forces in stations. The speed reduction is made on the basis that station tenability is not impaired during station evacuation in train fire/ station scenarios.

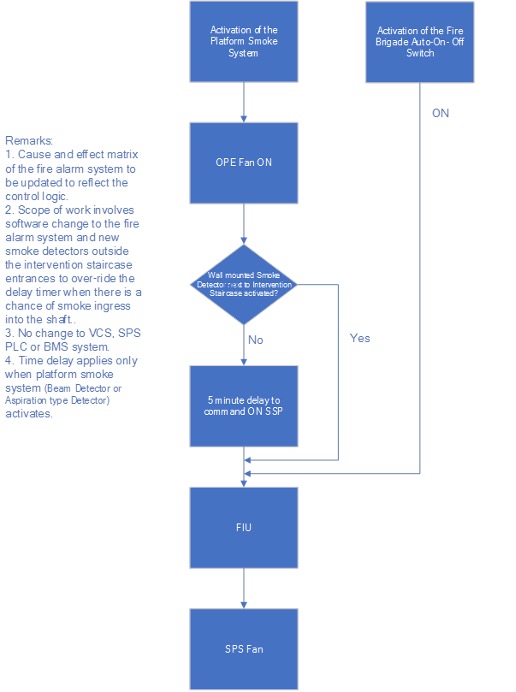

7 Door force optimisation- Delayed operation of staircase pressurisation (SPS) fan

The implemented strategy is to introduce a time delay to operate the SPS to allow PRM to journey, unassisted, through the relevant doors to the designated refuge areas, free from the air pressure influence due to the operation of the SPS. The time delay will apply only when the over platform smoke detection system is activated. The activation of the platform smoke detection system will also lead to operation of the platform smoke extraction system which will maintain the platform at a tenable condition for at least 15 minutes subsequent to the ignition of a platform fire. This will deter smoke from migrating into the intervention staircase during the time delay period. Figure 3 illustrates the control logic of the delay action.

Figure 3. SPS Operation Strategy: Process Control Diagram

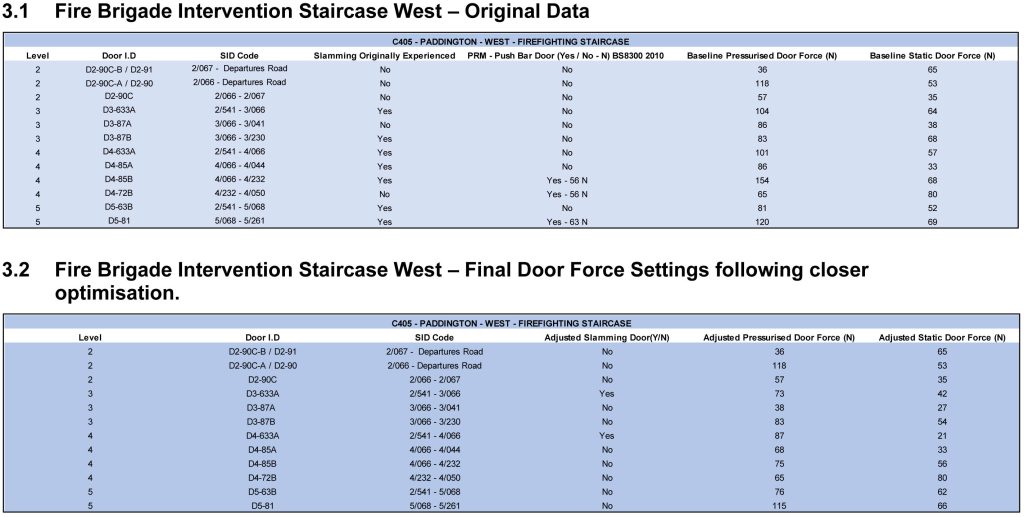

8 Reporting of commissioning results

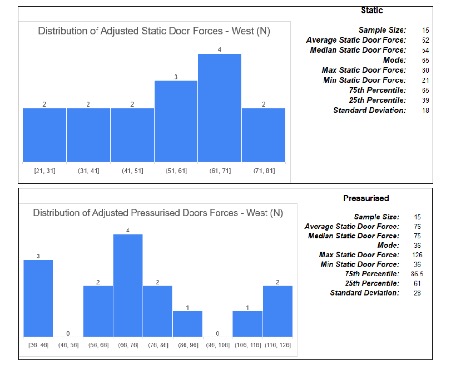

Figures 4 and 5 are examples of how commissioning information are presented to demonstrate that optimisation work has succeeded in reducing the non-conformance in acceptance criteria to a minimum. It is also important that the final settings of the doors are recorded in the handover files to provide the future maintainer with a benchmark for door settings should modifications occur to the doors in the future.

Figure 4. Sample report showing the outcome of the optimisation exercise

Figure 5. Sample report showing the analysis of the distribution of door force in static and dynamic conditions

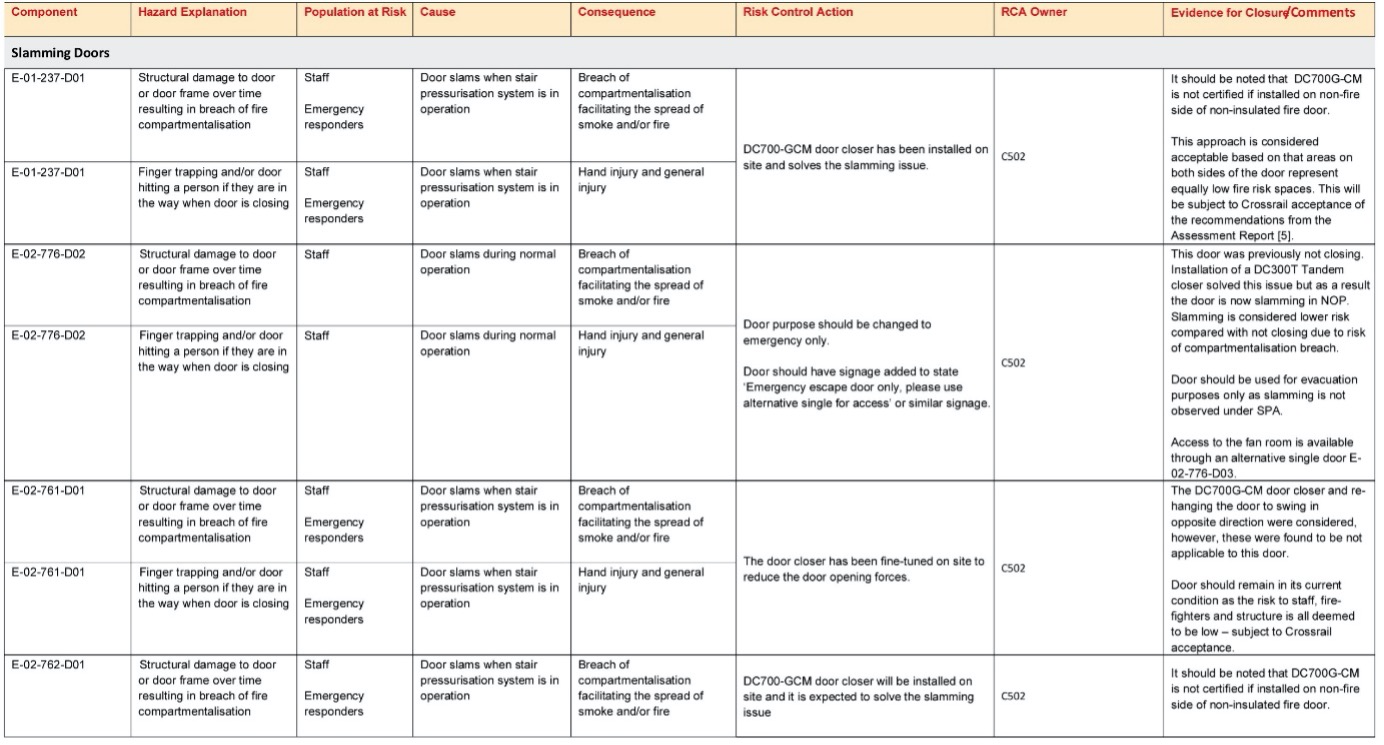

9 Management of residual risks

The hazard management process requires compliance with the Common Safety Method (CSM) regulations and the implementation of these principles to close out hazards identified at the previous design stage, and the additional hazards identified as part of the activities. The hazards identified are recorded in the Project Wide Hazard Register (PWHR) and should be closed out by application of one or more of the three CSM principles listed below:

- Codes of Practice;

- Comparison with similar systems (reference systems); and/or

- Explicit Risk Assessment.

The assurance evidence submitted by the station contractors will form the basis of the safety justification against emergency doors opening forces excessive for evacuating passengers. HAZID workshops were held as appropriate. The purpose of the workshop is for a multidisciplinary team to review and discuss the hazards applicable to the station so that they can be closed out by application of the CSM principles. In addition, the HAZID workshop acts as a forum for any new hazards not previously identified to be raised and discussed amongst stakeholders. The output of this HAZID Workshop contributes to the PWHR, which forms part of the station’s Safety Management System in ensuring that all Hazards identified within the scope of the Engineering Safety Management process are appropriately managed and reduced to As Low As Reasonably Practicable (ALARP).

Figure 6 illustrates typical outcomes of the HAZID workshop:

Figure 6. HAZID workshop

10 Lessons Learned

With a clear understanding of the railway operation principles, Crossrail was able to optimise door operating performance appropriate to meet the operational needs of station staff and commuters.

Because of the diverse operating requirements for doors (door opening force, force to release and re-latch the door gears, potential slamming upon closing etc) and variety of working environments (static and dynamic) that the doors will be exposed to, it is important that an optimisation process is in place during the commissioning stage to fine tune the door setting and to capture the door performance characteristic accurately for future door gear recalibration and recommissioning use.

-

Authors

Wing Fung PhD MSc BSc(Eng) CEng MCIBSE - Arcadis

Technical Director (MEP), Arcadis

Wing is is a Chartered Engineer with over 30 years’ experience as a technical specialist engaged in mass transit system planning, design, project management, technical assurance, commissioning, energy management, operation and maintenance, and asset renewal. Wing has been with the Crossrail project in the CRL Chief Engineer Group since 2013, overseeing mechanical design, systems integration and T&C.

Specialties: Building Services, Mechanical Engineering, Computational Fluid Dynamics, RAM studies, Systems Integration, Requirement Management, Testing and Commissioning.