Non-Road Mobile Machinery

Document

type: Micro-report

Author:

Cathy Myatt MA MSc

Publication

Date: 26/02/2016

-

Abstract

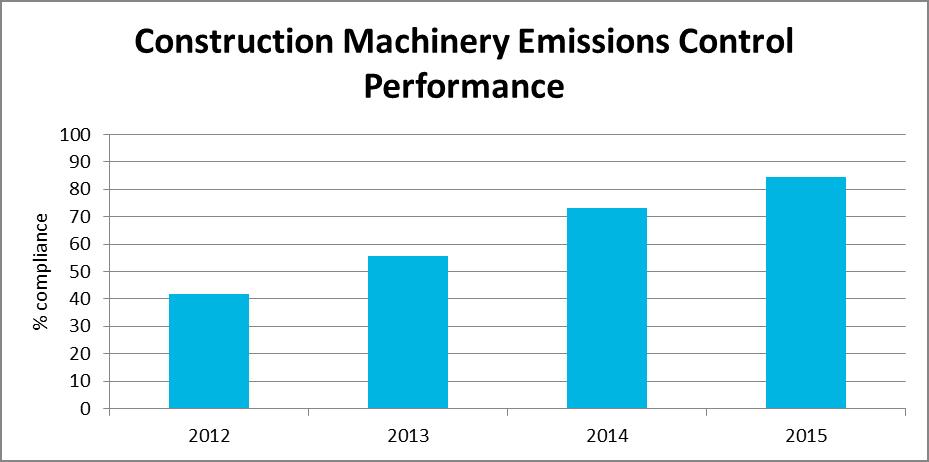

In 2012 less than 40% of all construction plant and equipment on Crossrail construction sites were fitted with diesel particulate filters or cleaner Euro Stage IIIB engines. By 2015 this had increased to over 80%. This learning legacy page describes the research undertaken and analysis of the various options for controlling emissions and the steps taken to implement the eventual solution and monitor compliance. It also includes a series of guidance notes that may be of use to Environment Managers or Project Managers in implementing the requirements and monitoring compliance on other projects and programmes.

-

Read the full document

Introduction

Diesel engine emissions control is traditionally at the manufacturer stage. All new Non-Road Mobile Machinery (NRMM) sold in the European Union (EU), since 1997, must conform to EU Directive 97/68 (as amended) which requires that, in order for NRMM to be first placed on the EU market for sale, engines (for use in NRMM) must be approved to demonstrate compliance with pollutant emission standards. These emissions standards are staged to allow continual improvements.

Figure 1 – Site Construction Vehicle

NRMM engines, and especially the larger ones that emit a lot of pollutant emissions, have long lifecycles, and engine fleet can take a long time to be replaced. Emissions control relating to NRMM that is already in use has been used successfully in Europe and the US (e.g. Switzerland and California). In the UK, London-based NRMM requirements were set out in the Mayor of London’s Best Practice Guidance (BPG) on the control of dust on construction sites [1]. In 2010 the ODA published at report to assess the cost effectiveness of retrofitting emissions control (using diesel particulate filters or DPFs) on NRMM within the Olympic Park. The use of retrofit was not pursued due to the findings that the incremental benefits of retrofitting DPFs was approximately half of the annual incremental costs (benefits were monetised based on a health impact assessment).

NRMM Requirements

Crossrail was the first UK infrastructure project to set out requirements for emissions control on construction machinery to bring about environmental benefits (as opposed to occupational health benefits in an underground setting). It was recognised that during the long construction period, there would be many construction sites spread across London, with each site having a range of large and medium size diesel engines working throughout the day, in many cases in close proximity to local communities.

A performance standard for NRMM was created that set out the standard that contractors were required to meet in relation to NRMM emissions control and how it should be demonstrated. This drew upon existing certification schemes within the UK and overseas. It required NRMM to be either Euro III(b) or to be fitted with a diesel particulate filter in order to reduce the emissions of particulate matter from the engine.The performance standard for all NRMM was defined as:

- NRMM with type approval engines Euro III(b) or IV; or

- NRMM with type approval engines Euro II or III(A) combined with after treatment devices listed under or with certification from:

- The Energy Savings Trust Energy Savings Trust Non-Road Mobile Machinery Register; orThe Swiss Federal Ordinance on Air Pollution Control (OAPC) FOEN Particulate Filter List; or

- Californian ARB Verification Classifications for Diesel Emission Control Strategies, Retrofit Device Verification Database Level 3; or

- Technology approved through the Transport for London (TfL) Low Emissions certification (LEC) process, Emission Stage Phase 4 achieving PM emissions limits Standard C, provided there is a proven record of off-road capabilities.

- An equivalent certification scheme provided that prior acceptance has been received from the Project Manager.

Research and Consultation

However in 2012 a Crossrail compliance review found that the NRMM requirements were not being achieved across the project. Research was undertaken including a wide consultation exercise involving construction contractors, the emission control retrofit industry, plant hire companies, plant manufacturers and organisations running similar emissions controls schemes overseas (e.g. Switzerland).

Data was collected on the type and duration of construction equipment to be used for Crossrail, how it would be obtained (e.g. hired or owned) and the cost, practicality and availability of emissions control technology. The costs and benefits of implementation were analysed.

The research identified a difficulty in procuring the latest emission standards engines for some equipment and a hesitation in the construction industry to embrace retrofit options. There was a lack of understanding over the financial costs and practical aspects of implementation and concerns relating to technical operation, safety and maintenance. Analysis showed that whilst the larger equipment had the greatest potential for emissions savings, this was also associated with the greatest costs.Final Solution

In response to these concerns, a collaborative approach, working with Tier 1 contractors, was adopted with the aim of finding a solution that clearly defined the required standard of emissions control on the project, but which also addressed the issues surrounding implementation. The solution involved:

• A bespoke emissions control performance standard which set out what was required and how it should be demonstrated. This drew upon existing certification schemes within the UK and overseas.

• A phased approach to implementation, specifying an initial focus on medium sized equipment (where there was potential benefit in reducing emissions but also greater availability and practicality of fitting controls) and secondly on more difficult equipment.

• A regime for the use of dispensations, for example where equipment was required for very short term use or to allow works to continue whilst solutions were sought for more difficult equipment.

• Clear deadlines for compliance and a strong enforcement message backed up with regular reporting.

Information and guidance was issued to address the issues raised during consultation. A training programme and materials were developed including a field guide to allow site staff to identify equipment fitted with emissions controls. This was accompanied by comprehensive programme of training of staff and awareness-raising amongst the supply chain.

Performance Improvement

Table 1 – Emissions Control Performance

In 2012, there was a lack of data on the emissions standards of NRMM. Of the 213 NRMM counted on sites only 139 had emissions data available and of those around 40% were compliant with Crossrail’s standards for emissions controls. By 2015, data availability had improved with over 300 NRMM counted on sites with emissions control data available for all of these. Compliance had improved to over 80%.

The Crossrail NRMM requirements helped drive the demand across the industry for NRMM fitted with emissions control and suppliers working on Crossrail upgraded their NRMM supply fleet to meet the requirements. The data gathered by Crossrail has been used by the Greater London Authority in developing their proposals for NRMM in the Ultra Low Emissions Zone (ULEZ) for London [2] which mean that equivalent requirements to Crossrail will apply to construction sites in the central activity zone from September 2015, and the remainder of London from 2020. Crossrail has raised the bar in the industry for emissions controls on major projects and it is expected that major projects, such as HS2, will build on these requirements moving forward.Supporting Documents

The full description on Crossrail’s approach to diesel emissions controls for NRMM and a summary of the associated research and consultation undertaken can be found here:

• Implementation of NRMM Diesel Engine Emissions Control on Crossrail

Crossrail developed a series of guidance notes that may be of use to Environment Managers or Project Managers in implementing the requirements and monitoring compliance on other projects and programmes:

• Guidance on Diesel Engine Emissions from NRMM and Retrofitting with Diesel Particulate Filters

This document provided guidance to contractors on Crossrail’s requirements relating to diesel engine emissions from NRMM and retrofitting with Diesel Particulate Filters (DPF)• NRMM Diesel Engine Emissions – Field Guide to Identification of Diesel Engine Emission Compliance

This document was developed as a field guide for the identification of compliant and non-compliant NRMM.• NRMM Dispensation Proforma Guidance

This document was produced to ensure a proportional and consistent approach to dispensation decision making for qualifying plant. Each dispensation application was assessed on a case by case basis and understood within the context of the contract and the project as a wholeReferences

[1] Mayor of London; (2006). The control of dust and emissions from construction and demolition Best Practice Guidance.

[2] Mayor of London (2014) The Control of Dust and Emissions During Construction and Demolition. Supplementary Planning Guidance

-

Document Links

-

Authors

Cathy Myatt MA MSc - Crossrail Ltd

Cathy Myatt is the Environment Manager at Crossrail. She leads the environment function, with overall responsibility for assuring compliance with environmental requirements. Her involvement dates from 2003 and includes preparing and submitting the Environmental Statement and negotiation of environmental requirements through the parliamentary Select Committee. She designed and implemented the project’s EMS and was involved with the procurement and assurance of design and construction contracts. She has also driven continual improvement on the project using mechanisms such as best practice fora, the Green Line Recognition Scheme and the supplier performance assurance process. Cathy is also an Associate Lecturer at Birkbeck College, teaching on the MSc in Environment and Sustainability.