CRL Station Platform Baggage Fire Size

Document

type: Technical Paper

Author:

Mary Sheehan, Sarah Ward, ICE Publishing

Publication

Date: 09/07/2018

-

Abstract

The Crossrail project (consistent with best industry practice) had a need to establish the ‘Design Fire Sizes’ for purposes of calculating various system/s (such as ventilation and fire suppression, detection etc) so that the characteristics and performance of such equipment can be specified in the design as adequate for the foreseen hazard/risk.

CRL commissioned BRE Global (BRE) to undertake a series of test burns to determine rate of heat release rate (HRR) from typical luggage items. Initial tests were undertaken in June 2010 and showed a slow spread of the fire over the surface of the luggage achieving a peak heat release rate of between 50 to 300kW. The conclusion from BRE noted that the fire remained on the surface of the luggage and contents within, and had the contents of the luggage spread to cover a larger surface area then the peak heat release rate may have been higher.

Additional tests were undertaken in January 2011 to include aerosol cans and nail polish remover within the luggage. The addition of aerosol cans to luggage items had an effect on the way the in which the luggage burned because the cans were consumed by the fire in such a way as to cause them to fail catastrophically. The burning items were spread out a distance away from the seat of the fire, and in some cases these items continued to burn and caused secondary ignitions. The fire grew at the same growth rate as in the initial tests, until the aerosol can exploded. The highest (momentary) peak HRR produced was 733kW.

Based on the results of the series of BRE fire tests, the preliminary project assumption of a likely baggage fire size with a potential HRR of not greater than 1.1MW was confirmed. This was extrapolated from the highest tested HRR, inflated by a significant safety margin to account for unknown variables.

-

Read the full document

1 Introduction

At the inception of the design of smoke ventilation and extraction systems from the platform areas, Crossrail (CRL) initially stipulated a baggage fire size of 1.1MW. This original fire size was based on the findings within Prescription in Flight, July 2002, an article from Focus: Building Design. The fire size within was determined by ‘bags on a piled high luggage trolley’ which is unrepresentative of the likely fire scenario on the CRL system. As a result, and to provide both due diligence and an audit trail, CRL instructed BRE to undertake fire tests on ‘typical’ pieces of luggage which are likely to be found on the CRL system. The findings from the BRE fire tests were gathered and discussed to conclude the appropriate design fire size for a baggage fire for the CRL project, and to determine if the originally proposed 1.1MW design fire size is appropriate.

2 Baggage Fire Size Paper and Test Results

2.1 Origin of the existing project wide baggage fire size

As stated above, CRL initially stipulated a design fire size of 1.1MW. This figure originated from the article “Prescription in Flight” from Focus: Building Design. This article discussed the fire safety engineering used to validate the fire strategy for the new Terminal 3 at Changi Airport in Singapore.

Within this article it was identified that the worst-case uncontrollable fuel load that could reasonably occur within the Main Space of the airport was passengers’ luggage.

Within “Prescription in Flight”, results from fire tests conducted by the Building Research Establishments fire research department (FRS) for the Brussels International Airport Company (BIAC) are used to identify the burning behaviour of both carry-on bags and luggage bags, it was identified that an arson fire involving two carry-on bags touching and burning simultaneously with a peak heat release rate of 500kW would be an appropriate “air side” fire size.

When ascertaining the appropriate luggage fire size “land side” of the airport, it was identified that trolleys piled with bags, both prior to checking in and after collection in the baggage claim hall represented the likely greatest hazard. Two fire tests were undertaken on piled-high luggage trolleys, one with sprinklers operating and the other without sprinklers operating.

Since CRL are not installing sprinklers/suppression within the public areas, the test result from the un-sprinklered fire test was adopted by the project. The result of this test suggested adopting a steady state design fire with a heat release rate of 1.1MW. Given 1.1MW is based on one test result, on a trolley piled with bags; this is unrepresentative of the likely fire scenario on the CRL system.

It is also worth noting the bags were filled with “clothing and other representative materials”; the exact content of the bags is unknown as it is not stated within the article.

2.2 BRE fire tests

Since the article above refers to test results from one un-sprinklered piled luggage trolley, which is not representative of the likely scenario on CRL, CRL instructed BRE to undertake a number of tests to ascertain the fire size of likely luggage scenarios.

The tests were commissioned to examine; record and report on the fire behaviour of the various luggage scenarios envisaged on the CRL system. The luggage items varied in size from a small aircraft cabin bag (carry-on sized) to large aircraft check-in sized bags.

To address the risk from electronics, a laptop computer and case were tested. In order to obtain a representative fill for the luggage items under test and so not to put a bias on any particular type or size of luggage, a selection of clothing types were placed in each of the suitcase (i.e. a mixture of both natural and man-made fabrics). All of the clothing items where obtained from charity shops and contained a mixture of both men’s, women’s and children’s clothing. No items which could be deemed as dangerous or would have significantly added to the fire in their own right were added. Each luggage item had a travel hair dryer, which consisted of a rigid plastic body and electrical plug and flex.

2.2.1 Testing Method

The correlation between these tests (commonly referred to as Single Burning Item (SBI) Test; and tests conducted at various facilities (such as extant at BRE Watford) commonly referred to as ‘Large Scale Fire Performance Tests’ (LSFP) were considered. The SBI tests was determined to be the most appropriate testing method for individual suitcase type baggage in the Crossrail environment, particularly at platform level. This is because;

- The Crossrail design size fire assumes a limited amount of moveable (i.e. luggage or similar) combustibles due to the nature of the demise and the planned control measures. It is simply not realistic to assume that larger fire sources than can reasonably be carried onto the platforms would be involved in a ‘moveable’ fire scenario.

- The LSFP is intended to evaluate/examine, amongst other things, the reaction to fire of building materials used in the construction of buildings. This is largely irrelevant as it is assumed, correctly that within the Crossrail demise, and especially in a sub-surface environment there is rigid control of materials, mostly with little or no combustibility and compliant, in most cases with LU Fire Safety Performance of Materials Category 1 Standard 1-085. Consequently, the Crossrail fire on the platform is very unlikely to develop into a ‘large scale’ fire involving more than the suitcases measured in the SBI.

2.2.2 Smoke Output/Visibility obscuration

The tests conducted did not fully interrogated nor report on the amounts of smoke (products of combustion) which may impact on visibility/soot yield etc. This arises due to the limited scope of the tests, compounded by unknowns such as ‘average suitcase contents’. It is well understood that differing materials burn at different rates and emit differing quantities of smoke. Hence, the results have not commented specifically on the ‘degree of accuracy’ of the tests and the likely ability to replicate such results in actual fires.

The Crossrail Modelling Design Manual, C124-MMD-N2-GML-CR001-00001, states, in part;

“The specific heat coefficients Cp,f and Cp,amb will be assumed identical for both fire and ambient conditions, and since the flame temperature is significantly higher than ambient, the second expression in the denominator can be neglected altogether. The production of smoke depends on the rate of burning of fuel, which is related to the instantaneous fire heat release rate, heat of combustion and the combustion efficiency. Similarly, the soot yield is determined from an estimation of the fuel being burned. Therefore, the visibility at any location in the computational domain can be estimated at any time from a knowledge of the smoke produced by the fire”

It can be seen from the above that assumptions have been made regarding the material involved and the assumed rate/efficiency of combustion. A measure of variance in these parameters needs to be considered in establishing a ‘reasonable case base fire size.

2.3 Day One fire tests

Five tests were undertaken in June 2010 at BRE facilities in Watford, London. The tests were conducted by BRE staff, and witnessed by representatives from London Fire Brigade; London Underground (Fire Engineer); Network Rail (Fire Engineer) and two representatives from CRL.

The tests results are documented in the BRE Report “Measurement of the rate of heat release from luggage items” and are summarised below:

- Test 1: Two carry-on sized pieces of luggage

- Test 2: One check-in sized piece of luggage

- Test 3: One over sized check-in piece of luggage

- Test 4: One carry-on sized piece of luggage

- Test 5: Laptop and laptop bag

Table 1 below provides an overview of the results from the fire tests.

Table 1: Day One Fire Tests Results

Test No Luggage Item Mass when filled

(kg)

Peak Heat Release rate (kW) 1 1 9.24 Total

16.05

284 2 6.81 2 3 17.26 119 3 4 27.7 158 4 5 5.5 143 5 6 6.31 57 The BRE report comments that for each of the tests, ignition of the luggage was very difficult. The ignition source for each test was a standard cigarette lighter which was held for a period of time, up to 20s, until the flaming on the luggage item was self sustaining. In the case of test 2 and 5, the flames self extinguished and required a further ignition. Test 3 and 4 required the ignition source to be held at the wheels of the luggage as the ignition could not be achieved at the fabric of the luggage item.

Below are brief descriptions of the tests.

2.3.1.1 Test 1: Two carry-on sized pieces of luggage

The first test was two small cases; both approximately the size of a carry on case, 6.81kg and 9.2kg. The larger of the two cases was ignited using a standard cigarette lighter with the fire left to grow without any interference.

The following was encountered during the testing:

- The fire did not spread quickly from the larger case to the smaller case.

- After the fire was extinguished, while the test area was being cleared; it was evident that approximately 30% of the luggage within the case was untouched by the fire. It is believed this happened as a result of char forming around the outside of the case. This charring caused air not to reach all the contents and therefore this content did not become involved in the fire.

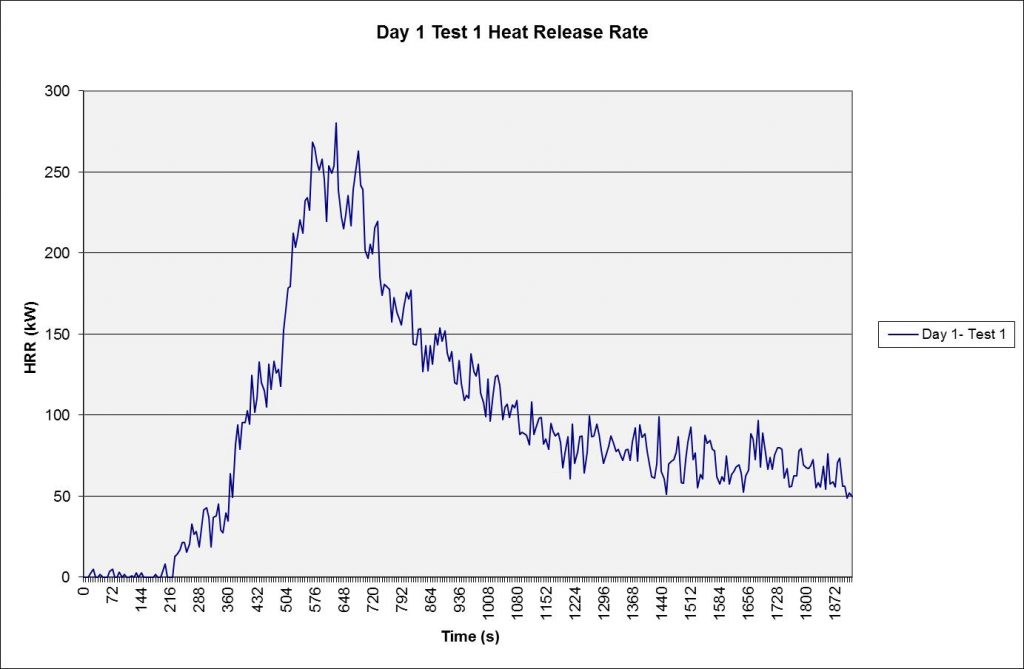

- This test found that the fire grew slowly with a peak HRR for this test of 284kW, shown in figure 1 below. Peak heat release was measured approximately 10 minutes after ignition.

Figure 1: Heat Release Rate for 2 no. Carry-on sized luggage items

2.3.1.2 Test 2: One check-in sized piece of luggage

The second test was undertaken on 1 no. large case; approximately the size of a check in case, 17.26kg. The case was ignited using a standard lighter with the fire left to grow without any interference.

The following was encountered during the testing:

- The ignition of the suitcase was difficult. Originally the lighter was applied to the fabric of the case; however this ignited and quenched. The lighter was then applied to the plastic around the wheel area. This area ignited and grew.

- After the fire was extinguished, while the test area was being cleared; it was found that approximately 30-35% of the luggage within the centre of the case was untouched by the fire. It is believed this happened, as with the previous test, as a result of char forming around the outside of the case, resulting in air not reaching all the contents and therefore the untouched content did not become involved in the fire.

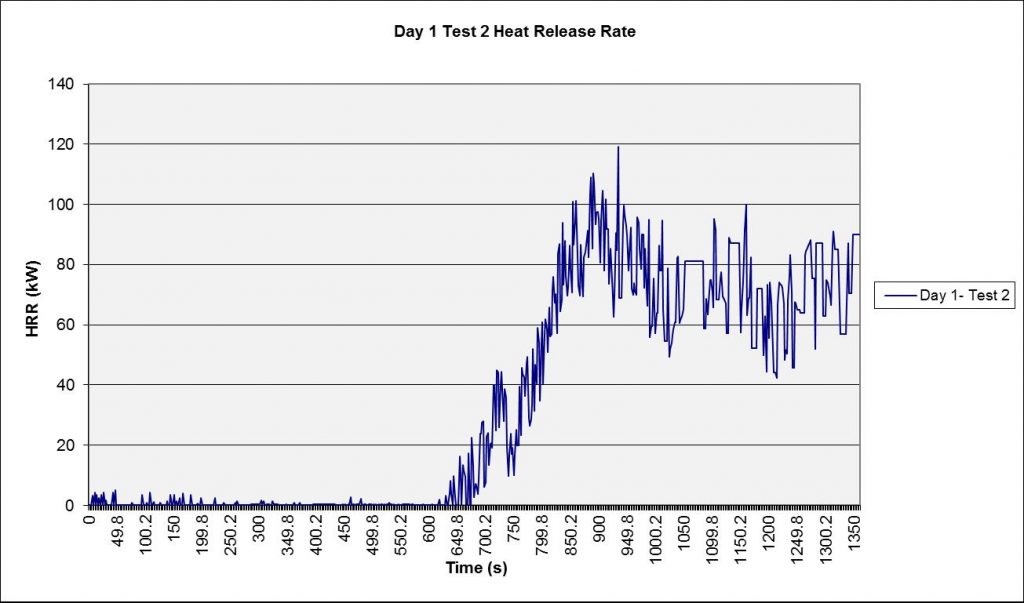

- This test found that the fire grew slowly with a peak HRR of 199kW, (reached approximately 15 minutes after ignition) shown in figure 2 below

Figure 2: Heat Release Rate for 1 no. check-in sized piece of luggage

2.3.1.3 Test 3: One over sized check-in piece of luggage

The third test was one over sized large case; 27.7kg. The case was ignited using a standard lighter with the fire left to grow without any interference.

The following was encountered as part the testing:

- As with the previous case, the ignition of the suitcase was difficult. Originally the lighter was applied to the fabric of the case; however this ignited and quenched. The lighter was then applied to the plastic around the wheel area. This area ignited and grew.

- After the fire was extinguished, while the test area was being cleared; it was evident that approximately 60% of the luggage within the centre of the case was untouched by the fire. It is believed this happened, as with the previous test, as a result of char forming around the outside of the case. This charring restricted air reaching all the contents and therefore this untouched content did not become involved in the fire.

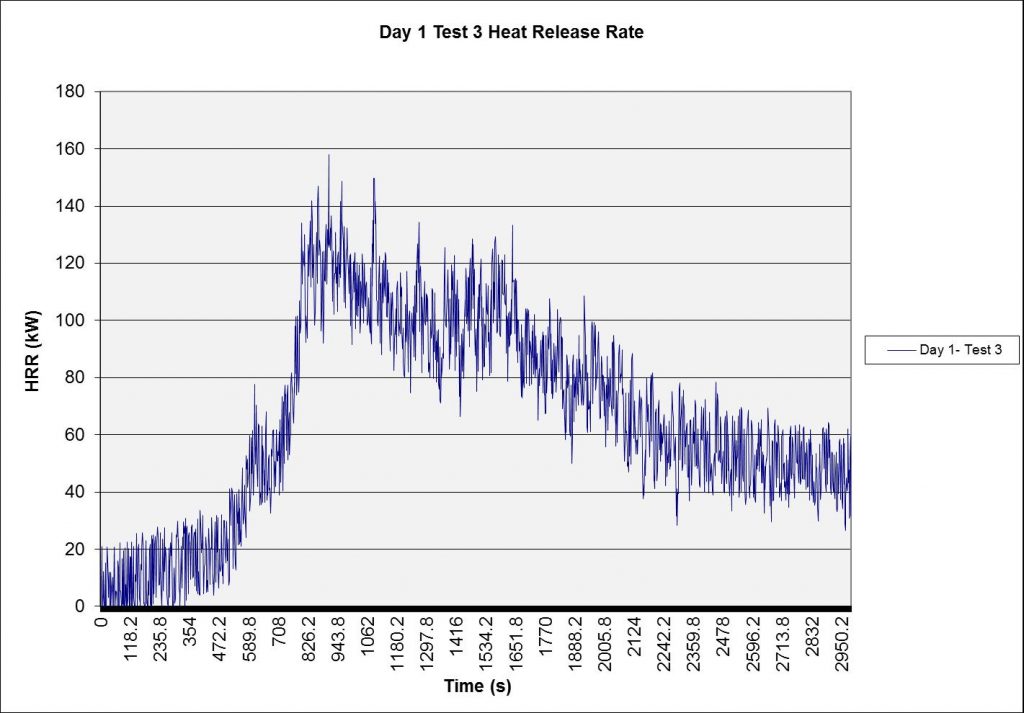

- This test found that the fire grew slowly with a peak HRR of 158kW, (reached approximately 15 minutes after ignition) as shown in figure 3 below.

Figure 3 Heat Release Rate for 1 no. over sized check-in piece of luggage

2.3.1.4 Test 4: One carry-on sized piece of luggage

The fourth test was one small case; lightly packed and approximately the size of a carry on case, 5.55kg. The case was ignited using a standard lighter with the fire left to grow without any interference.

The following was encountered as part the testing:

- As with the previous case, the ignition of the suitcase was difficult. As with the previous tests, it was the plastic surrounding the wheel of the case which ignited.

- After the fire was extinguished, while the test area was being cleared; it was evident that approximately 15% of the luggage within the centre of the case was untouched by the fire. It is believed this happened, as with the previous tests, as a result of char forming around the outside of the case. This charring restricted air reaching all the contents and therefore this untouched content did not become involved in the fire.

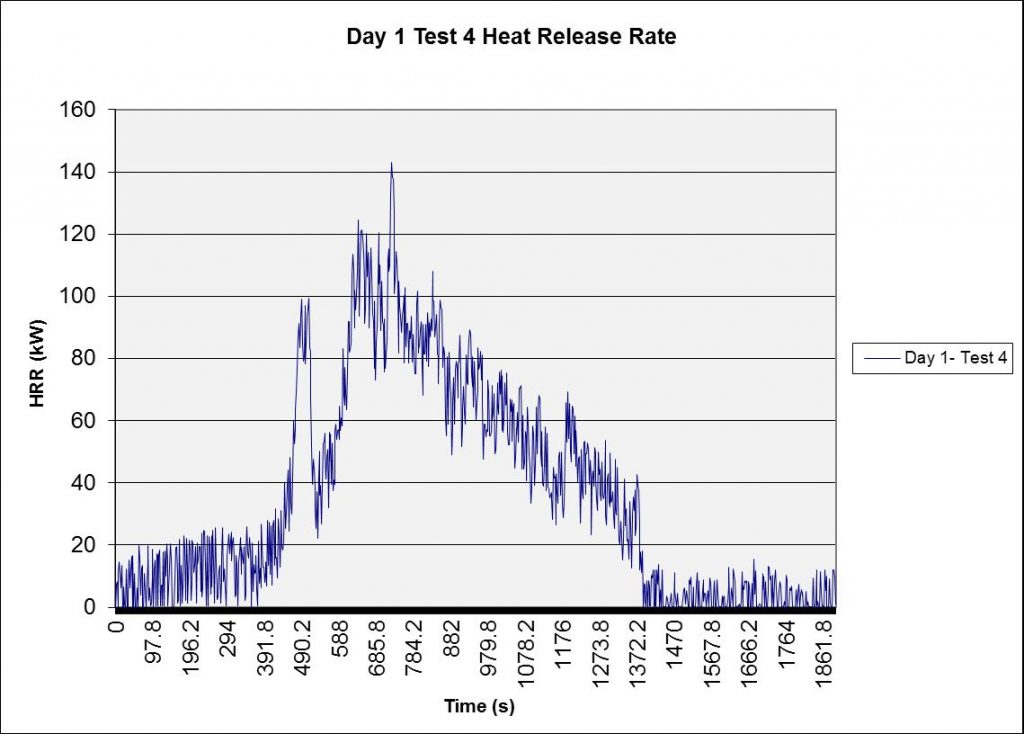

- This test found that the fire grew slowly with a peak HRR of 143kW, (reached approximately 12 minutes after ignition) as shown in figure 4 below.

Figure 4: Heat Release Rate for 1 no. carry-on sized piece of luggage

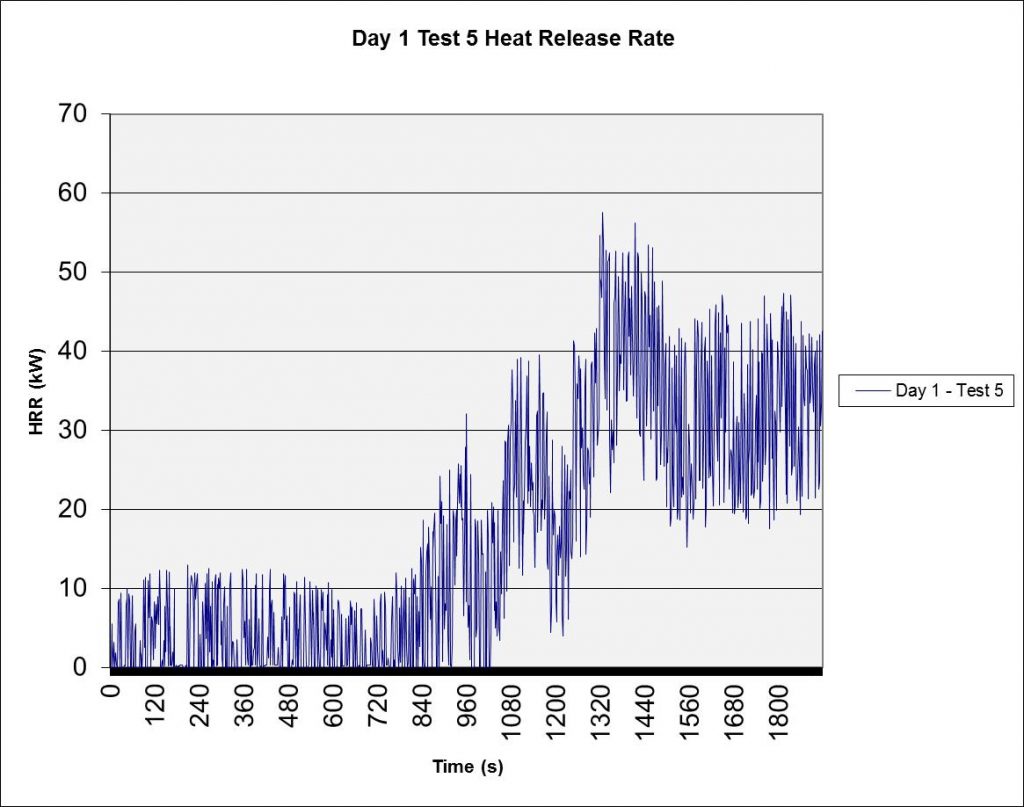

2.3.1.5 Test 5: Laptop and laptop bag

The fifth test was a laptop bag containing a laptop and a typical work folder, 6.31kg. The bag was ignited using a standard lighter with the fire left to grow without any interference.

The following was encountered as part the testing:

- As with the previous case, the ignition of the laptop bag was difficult. Originally the lighter was applied to the fabric of the laptop bag; however this ignited and quenched. The lighter was then applied to the fabric near the zip. This area ignited with some difficulty but grew.

- This test found that the fire grew slowly with a peak HRR of 57kW, (reached approximately 24 minutes after ignition) as shown in figure 5 below.

Figure 5: Heat Release Rate for laptop + bag

2.3.1.6 Conclusion from Test Results

From the fire testing the following was noted:

- The baggage was difficult to ignite.

- The maximum peak HRR achieved was 284kW, with all tests growing slowly.

- The peak HRR was not related to the fuel load (mass); it was related to the surface area available.

- The entire fuel load was not involved in the fire. After the fire was extinguished, while the test area was being cleared; it was evident that approximately between 15%-30% of the luggage within the centre of the case was untouched by the fire. It is believed this happened as a result of char forming around the outside of the case. This charring restricted air reaching all the contents and therefore this untouched content did not become involved in the fire.

2.3.2 Day One Overall Conclusions

It was observed that in most cases the items of luggage were not easily ignited by a typical cigarette lighter. Apart from test 1, the initial attempts to ignite the items of luggage resulted in a failure. Where the item failed to ignite by application of the flame to the main body material a secondary application of the ignition source was made to the wheel and the surrounding plastic housing. In all the tests where secondary ignition attempts were made on the item’s wheel, ignition resulted and there was the subsequent spread of fire to involve the whole item.

The observed mechanism of burning was a slow spread of the fire over the surface of the luggage item and from the test undertaken; a fully packed luggage item gave a peak heat release of between 50 to 300kW. While it is possible to get the fire to spread to all the surfaces of the items of luggage tested, it was apparent that the contents (clothing etc…) stored in the luggage, kept their shape and the fire remained on the surface. Had the contents of the luggage items spread to cover a larger surface area the peak heat release seen may have been higher.

It was observed during the tests that pool fires of molten plastic formed around the area of ignition but generally did not spread far from the luggage item.

2.3.3 Recommendations from stakeholders

Following the issue of the BRE report, a stakeholders meeting was held for discussion. A concern was raised regarding the omission of common accelerants in the luggage. It was generally accepted by those present that it would not be unreasonable to use the peak HRR recorded of 284kW and apply a factor of safety of 2; therefore stipulating a baggage fire size of 600kW with a slow fire growth. It was agreed the factor of safety of 2 should allow for uncertainties such as aerosol cans etc.

However to ensure all expressed and known concerns were dealt with, CRL instructed BRE to undertake a second day of fire testing. This second series of tests were supplementary to the original tests; and conducted to measure relevant HRR from ‘sample’ items of luggage packed with various items of clothing, with aerosols/nail varnish removers (solvent bottles), which were considered to be the likely accelerants found in carried or accompanied passenger baggage. The details of further ‘Day Two’ tests are detailed in the following section.

2.4 Day two fire tests

Three additional tests were undertaken in January 2011 at BRE facilities in Watford, London with the purpose of ascertaining the impact of everyday accelerants, in this case aerosol cans and nail varnish remover, on the fire behaviour of the items of baggage. BRE staff members witnessed the tests. The tests were as follows:

Due to ignition problems in the previous tests, a gas burner was used as the ignition source instead of the previously used standard cigarette lighter.

The test results are documented in the BRE Report “Measurement of the rate of heat release from luggage items with Aerosol cans and Nail Polish Remover” found in Appendix A and summarised below:

- Test 1: Two carry – on sized pieces of luggage both containing an aerosol can and a bottle of nail varnish remover

- Test 2: Two small check-in sized pieces of luggage both containing an aerosol can

- Test 3: One check-in sized piece of luggage containing an aerosol can and a bottle of nail varnish remover.

Table 2 below provides an overview of the results from the fire tests.

Table 2: Day Two Fire Test Results

Test No Luggage Item Mass when filled

(kg)

Peak Heat Release rate (kW) 1 1 9.24 Total

17.84

733 2 8.6 2 3 12.4 Total

24.8

613 4 12.4 3 5 16.9 660 2.4.1.1 Test 1: Two carry – on sized pieces of luggage both containing an aerosol can and a bottle of nail varnish remover.

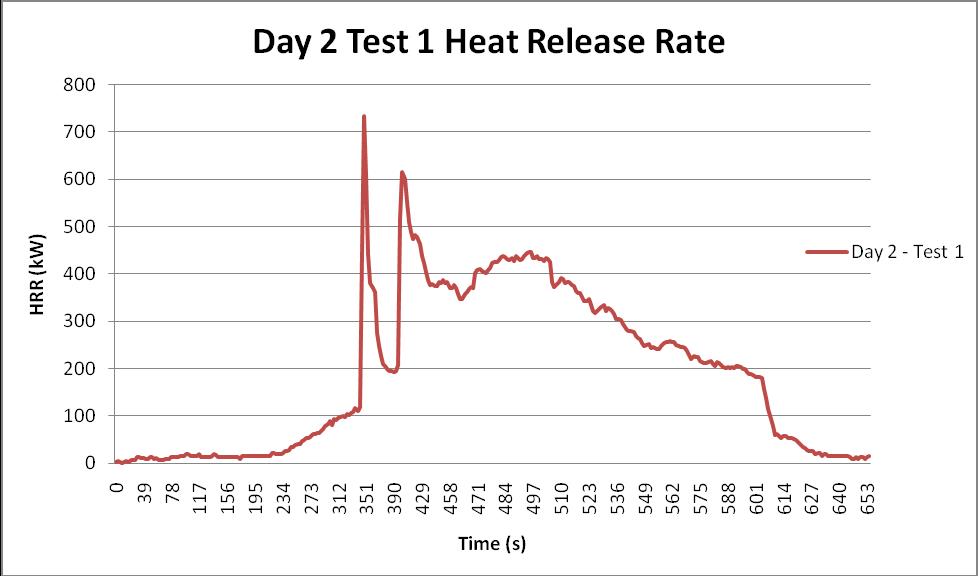

The first test was two carry – on sized cases; 9.24 kg and 8.6kg; similar to Day 1- test 1. Both cases contained an aerosol can and a bottle of nail varnish remover, located within the front pouch inside the case.

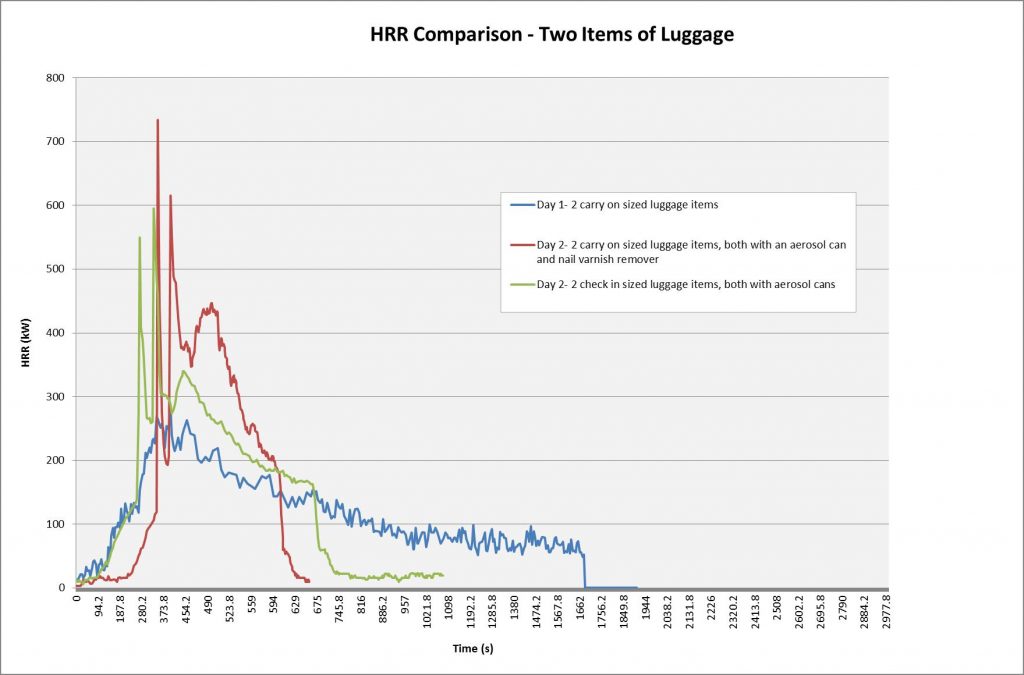

One case was ignited using the application of a gas burner for a period of 13s and reached a peak HRR of 733kW, as show in figure 6 below.

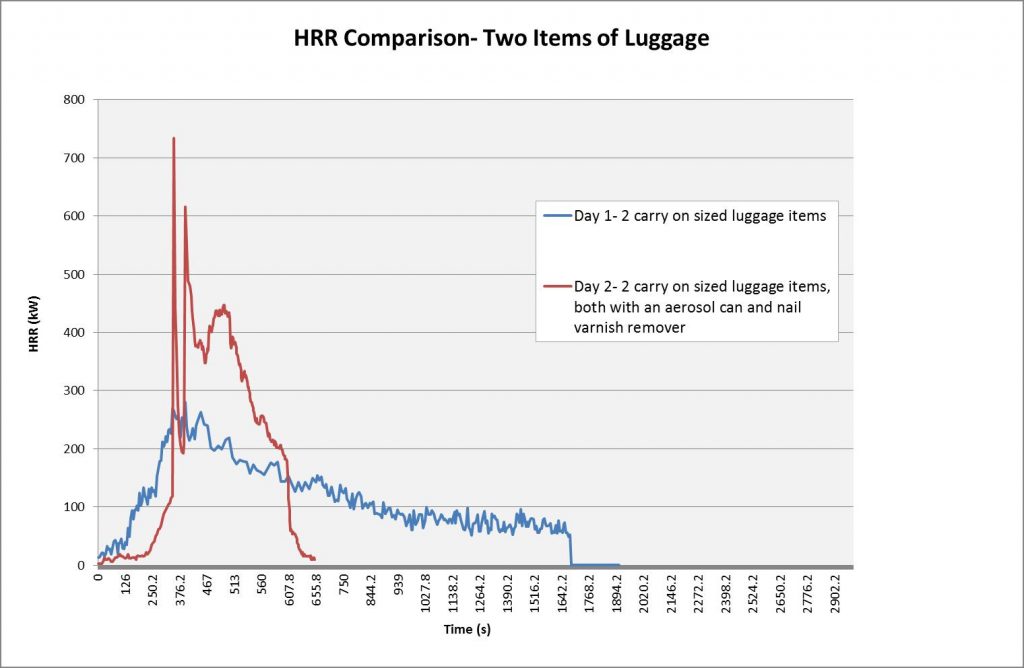

Figure 7 shows the HRR curves for Day 1-Test 1 and Day 2-test 1, both have comparative layout and Mass, removing the time lapse from Day 1 data due to the different ignition sources.

Figure 6 Day 2 Test 1 Heat Release Rate Curve

The following was encountered during the Test 1:

- The nail varnish remover had no impact on the fire behaviour.

- There are two spikes on the HRR chart above, these represent when the aerosol cans (one located in each case) exploded.

- When both the aerosol cans exploded, they sent burning gas and debris away from the seat of the fire.

- The spikes representing the exploding aerosol cans only last approximately 20s.

- The HRR decreased at a greater rate than the previous test.

Figure 7: Day 2 Test and Day 1 Test 1 Comparative HRR Chart

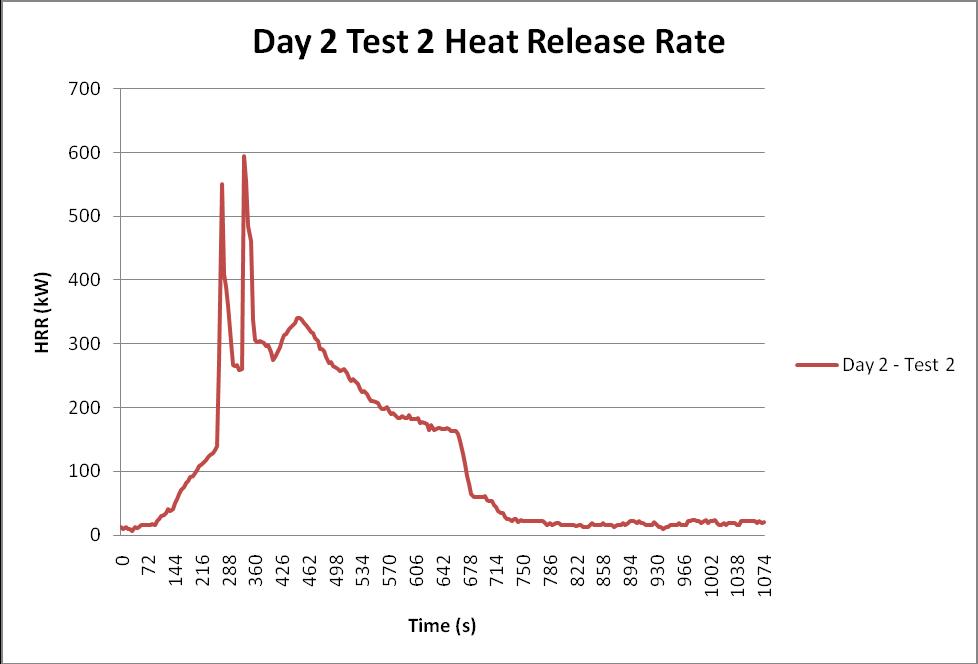

2.4.1.2 Test 2: Two small check – in sized pieces of luggage both containing an aerosol can

The second test was two small check in sized or carry-on sized cases; both 12.4kg; similar to Day 1- test 1 and Day 2- test 1. Both cases contained an aerosol can only, located within the front pouch inside the case.

One case was ignited using the application of a gas burner for a period of 13s and reached a peak HRR of 613kW, as show in figure 8 below.

Figure 9 shows the HRR rate curves for Day 1-Test 1, Day 2- Test 1and Day 2-Test 2 as all three have comparative layout and mass.

Figure 8: Day 2 Test 2 Heat Release Rate Curve

The following was encountered during the Test 2:

- There are two spikes on the HRR chart above, these represent when the aerosol cans (one located in each case) exploded.

- When both the aerosol cans exploded, they sent burning gas and debris away from the seat of the fire.

- The spikes representing the exploding aerosol cans only last approximately 30-40s.

- The HRR decreased at a greater rate than the previous test.

Figure 9: Day 2 Test 1, Day 2 Test 2 and Day 1 Test 1 Comparative HRR Chart

2.4.1.3 Test 3: One check-in sized piece of luggage containing an aerosol can and a bottle of nail varnish remover.

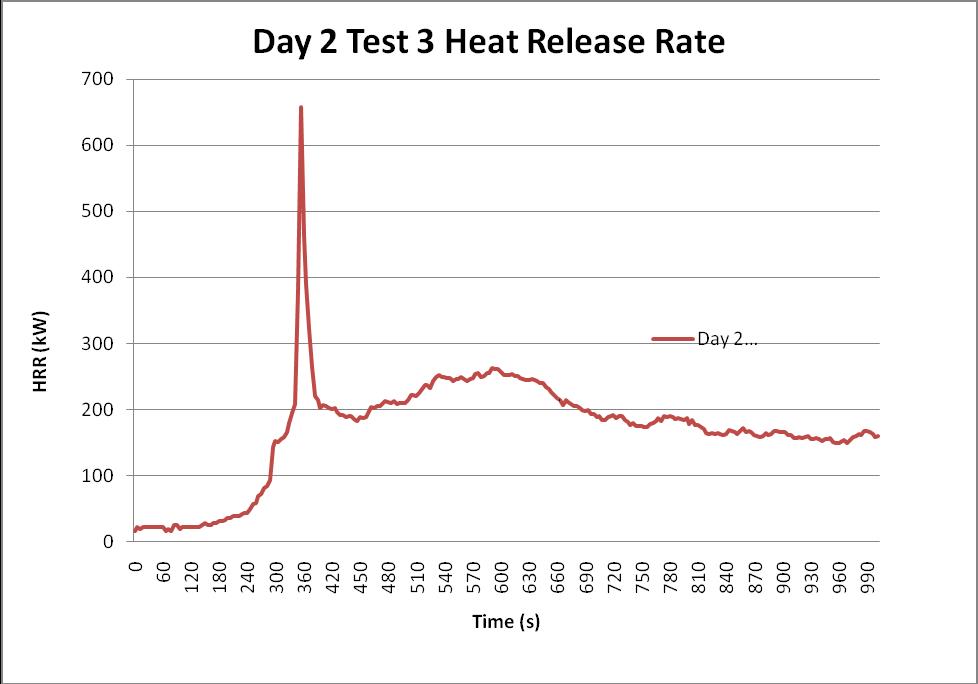

The third test was on one check in sized cases; approximately 16.9kg. This case contained both an aerosol can and a bottle of nail varnish remover, located within the front pouch inside the case.

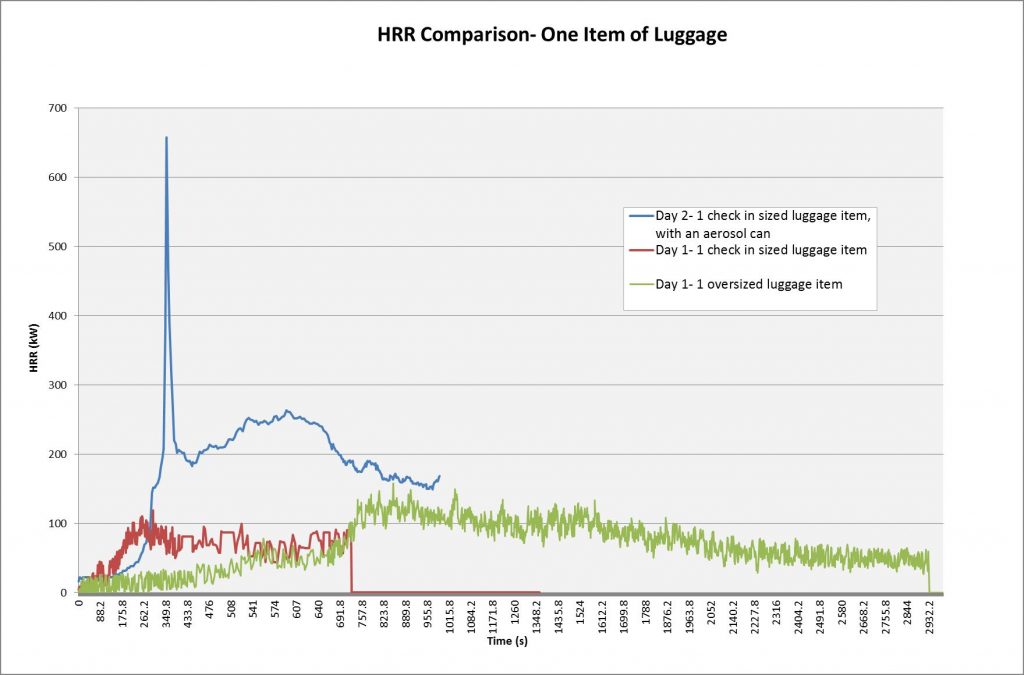

The case was ignited using the application of a gas burner for a period of 17s and reached a peak HRR of 660kW, as show in figure 10 below.

Figure 11 shows the HRR rate curves for Day 1-Test 1, Day 2- Test 1and Day 2-Test 2 as all three have comparative layout and mass.

Figure 10: Day 2 Test 3 HRR Chart

The following was encountered during the Test 3:

- There is one spike on the HRR chart above, these represent when the aerosol can exploded.

- The spike representing the exploding aerosol can only last approximately 30s.

- The HRR decreased at a greater rate than the previous test.

Figure 11: One Item of baggage Comparative HRR Chart

2.4.2 Day Two Overall Conclusions

It was observed for all of the tests undertaken that the inclusion of aerosol cans in the luggage items gave rise of a fire ball and subsequent spike in the rate of heat release. In all tests the fire ball was in excess of 3m in width and discharged the contents of the can, and in some cases burning materials, away from the seat of the fire. Although the aerosol cans were not ignited directly, the fire in the luggage items was able to spread in such a way as to involve the aerosol can to such an extent that catastrophic failure of the aerosol can was observed. In none of the tests did any of the aerosols vent in a controlled manner. Although present, the contents of the nail polish remover bottles did not appear to have an observable effect on the rate of heat release, however it was observed that in test 3 small running fires were seen away from the seat of fire.

It is clear from the observations of the test series that the addition of aerosol cans to luggage items has an effect on the way in which they burn and that the cans will be consumed by the fire in such a way as to cause them to fail catastrophically. The failure of the aerosols is such that burning items were spread out some distance away from the seat of the fire, in most cases these items continued to burn and were capable of causing secondary ignitions. Observations suggest that it would be unlikely that the contents of the aerosol cans alone when ignited would be able to spread fire away from the initial seat of the fire. The predominant mechanism could be described as a rapid release of the contents of the can, with a rapid expansion of the flammable liquid and gases and subsequent ignition of the vapour cloud by the luggage fire. The resulting ignition of the vapours could best be described as an unconfined vapour cloud explosion.

3 Conclusions

3.1 Fire Size

From the “Prescription in Flight” July 2002 (‘PiF’) article the use of 1.1MW fire is based on a trolley piled with luggage; however this is not a likely scenario on the CRL network. The most likely scenario is 2 carry on pieces of luggage, which according to the PiF article has an applicable HRR of 500kW.

From the testing undertaken by BRE on Day 1 it was recommended to stipulate a peak HRR of 600kW, based on calculating the greatest HRR from the various tests and applying a safety factor of 2 (for unknown variables).

From the Day 2 testing, which incorporated common everyday accelerants, it is evident the accelerants had an impact on the fire behaviour. The fire grew at the same growth rate until the aerosol can exploded; producing a (highest) peak, momentary, HRR of 733kW.

From the testing it is worth noting it was not the luggage cases with the largest fire load which created the peak HRR. The fire tests conducted showed that some of the cases burned at an increasing rate for a time following sustained ignition but that HRR varied according to the cases orientation. Most were ignited at the wheels, with a standard lighter, whilst standing on their short edge but ‘toppled over’ to the side when the fire had consumed the wheels/base. The ‘toppling’ over of some of the cases was marked by a noticeable decrease in HRR.

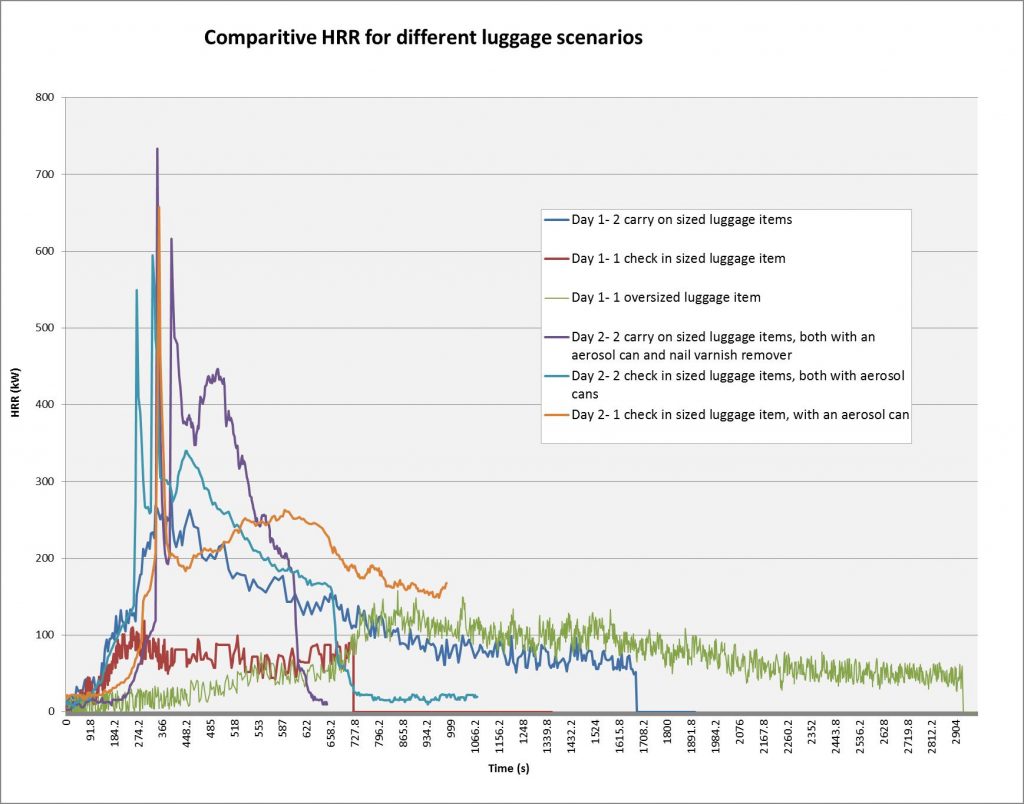

Figure 12 below illustrates the HRR test results for the most appropriate tests undertaken by BRE. This chart illustrates the aerosol cans’ impact on the behaviour of the fire with the peak HRR reaching 733kW for 2 carry-on sized cases.

Figure 12: HRR Chart with all test results

The significant spikes in all tests where spikes occurred (all tests involving aerosols) resulted from the aerosols exploding which created short-duration rapid growths in the HRR, followed in all tests by comparatively fast decline in HRR. The aerosols in the tests exploded after at least 4 minutes from ignition. These times and HRR may not always be replicated in further tests of similar nature, nor during actual fire scenarios, but do provide consistent indications of fire growth under these test conditions.

The momentary peaks (in the fire tests) were considered not significant to the design with regard to smoke extraction and escape/evacuation of platforms. Where tests showed such peaks (baggage containing aerosols) the higher peaks occurred after at least 4 minutes had passed, with the maximum peak HRR of 733kW. This is less than the design HRR of 1.1MW, which the smoke extract system has been designed for. All evacuees present should not be exposed to additional adverse conditions caused by the momentary peak HRR witnessed in the BRE tests.

Based on the results of the BRE fire tests (series), the preliminary project assumption of a likely baggage fire size with a potential Heat Release Rate (HRR) of not greater than 1.1MW was confirmed. This is extrapolated from the highest tested HRR inflated by a significant safety margin to account for unknown variables.

-

Authors

Sarah Ward - Crossrail Ltd

Sarah Ward is a Fire Engineer with Crossrail’s Chief Engineer’s Group. In this role, she provides technical assurance and guidance on fire engineering matters for all aspects of the central operating section of the project, including tunnels, stations, intermediate shafts, portals, systems, rolling stock and ancillary buildings. This includes establishing fire engineering requirements, maintaining the Crossrail fire safety engineering principles standard, developing the central operating section fire strategy and working with 3rd party stakeholders to review and approve the fire safety designs and assurance for each element of the design.

Sarah has worked on the Crossrail project since September 2012. She is seconded to Crossrail from AECOM, where she is a Principal Engineer in the Fire and Risk team. Prior to that, Sarah has worked in fire safety engineering since January 2005, and specialises in fire suppression and detection systems, fire strategies, fire risk assessments and fire brigade operations. She is a Member of the Institute of Fire Engineers.