Augmented Reality Trials on Crossrail

Document

type: Micro-report

Author:

Stephen Smith

Publication

Date: 14/03/2017

-

Abstract

Augmented Reality (AR) technology is rapidly evolving and has great potential to drive efficiencies and improve health and safety within the construction industry. This paper provides an overview of an AR trial undertaken at Custom House site on Crossrail in 2014. It highlights the key findings, practical considerations and potential additional uses for future consideration by other construction projects.

-

Read the full document

Introduction and Industry Context

Augmented Reality (AR) is defined as a live direct or indirect view of a physical, real-world environment whose elements are augmented (or supplemented) by virtual computer-generated sensory input such as sound, video, graphics or GPS data. In the construction industry this augmented information could be in the form of design, project controls and/or construction data linked to 2D / 3D / 4D models overlaid on the construction site, to facilitate decision-making and improve efficiencies in capturing construction records.

A pilot AR project was undertaken in 2014 at Custom House station focusing on the installation phase of the main station super structure. This pilot project included a Design for Six Sigma (DFSS) assessment at Custom House.

This report details the findings of this pilot and recommendations for future use of AR within the construction industry.What We Did

In early 2014 a 22-week AR pilot was sponsored by Crossrail part of which was implemented at Custom House. The project was led by the AR/VR Implementation Manager at Bechtel, and was supported by existing resources on the Crossrail project. The trial implemented a Bechtel developed AR mobile (iPad) application (herein referred to as the AR Solution) at Custom House to validate whether it brought process and quality efficiencies.

To design the process for using the AR Solution it was decided by the Six Sigma lead that the DFSS approach would be used. This approach differs from the standard Six Sigma DMAIC (Define, Measure, Analyse, Improve, Control) methodology which is traditionally used to improve an existing process. The main metrics focused on process cycle times and information quality (which it was assumed should lead to better decision making) and are listed in Table 1.

It is believed that AR has the potential to benefit construction in a number of areas (or “use cases”). The specific use case tested in this pilot focused on how construction progress information can be captured against an AR 3D model in the field and automatically pushed back into the 4D model environment to assist with project planning activities. The main three stages of the process are shown in Figure 1,

INSERT Figure 1 here (can’t seem to move it from end of this document but should be ok to insert when uploading to LL website)Figure 1: AR Process Steps

The steps break down as follows:

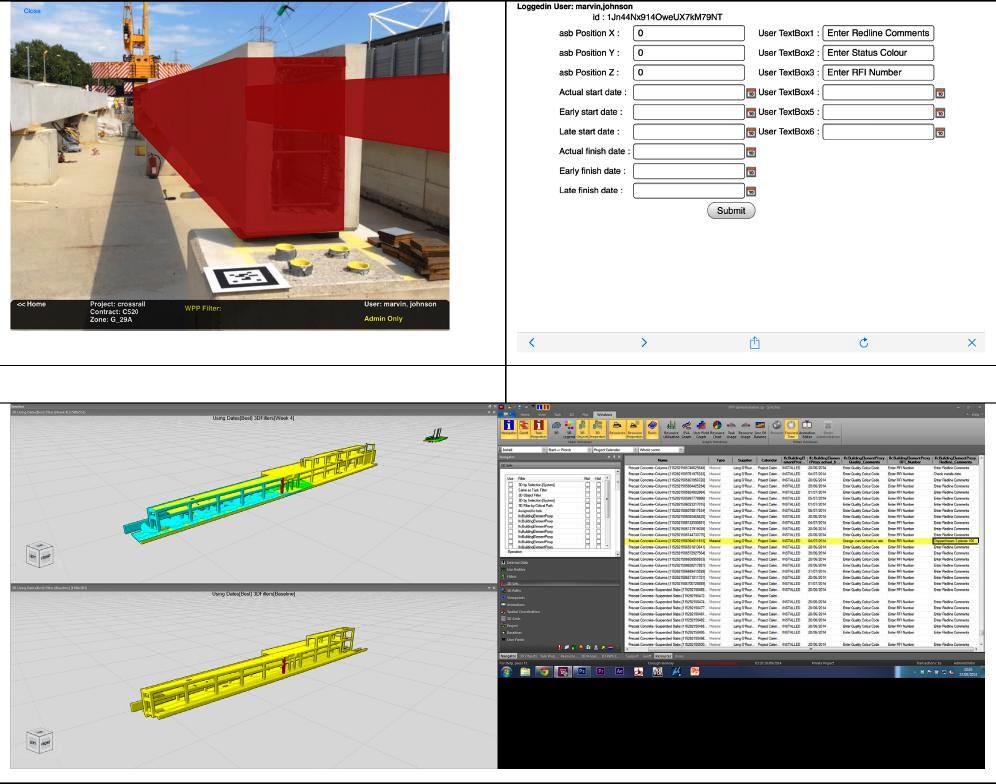

Step 1 – 3D Model (and linked attribute data) was pulled into the AR solution. The positioning of the model was done using the marker seen in image 1.

Step 2 – User clicks on an object in the 3D Model (e.g. Column) and the data entry screen allowed installation status and date fields to be entered.

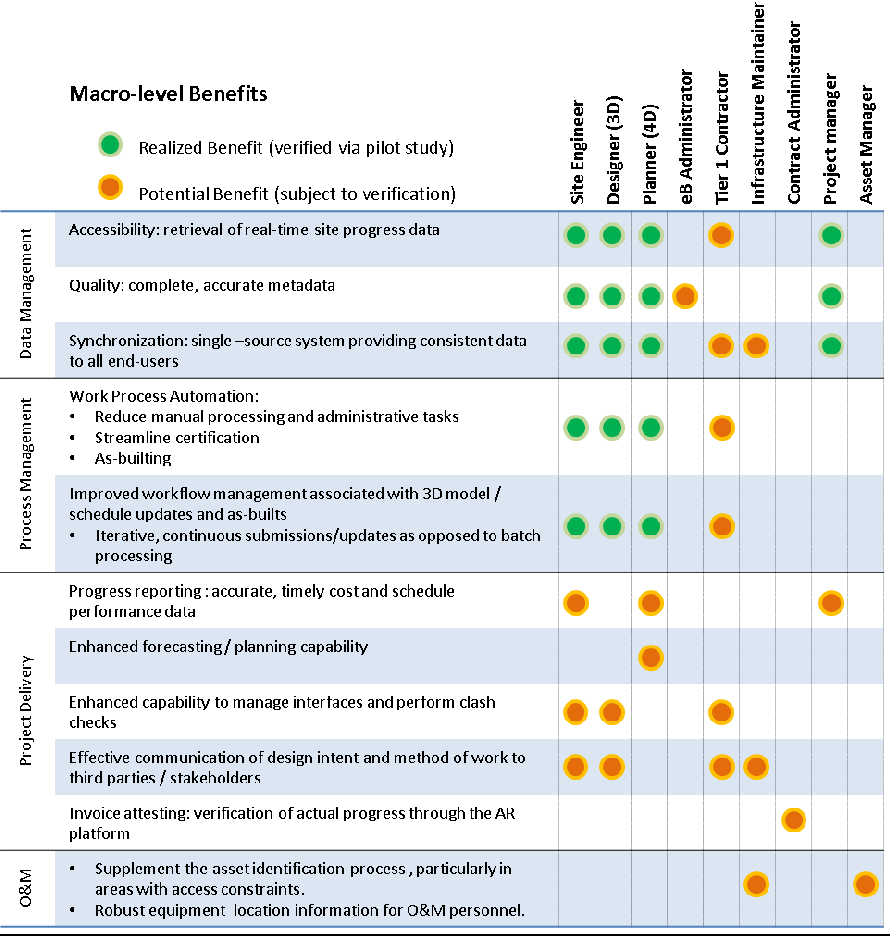

Step 3 – The data entered in Step 2 was automatically pushed back to the 4D Model in an application called Synchro Pro where the planner could see the status.For 7 weeks of the 22-week pilot the process outlined above was initiated at Custom House. The macro-level benefits realised are detailed in Table 1, organised by project participant. The benefits that were realised, i.e. verified through the pilot, are indicated in green and additional anticipated benefits that were not verified are indicated in orange. The most significant productivity gains were seen under the “Process Management” benefits section. The cycle time for the traditional process was approximately 96 work-hours and with the DFSS AR Solution this was reduced by 73% to 26 work-hours. The AR Solution automated non-value added tasks that the planners acknowledged freed them up to more effectively forward plan. Additional qualitative benefits were identified, such as improved accuracy of the reporting, are noted in Table 1.

Table 1: Realised and Potential Benefits Overview

At the time of the trial there were a number of technical constraints identified that factor towards successful implementation of an AR solutions. In order for the AR content to be accurately positioned within the real world it relies upon a combination of content management systems, tracking & positional technology, data processing, visualisation and mobile devices (e.g. iPad). These constraints should be recognised and are outlined in the recommendations section below for future projects to be aware of. Technology has rapidly advanced in these areas over the past few years possibly making these considerations less of an issue.

Lessons Learned

The pilot successfully demonstrated a significant process cycle time improvement from 96 work-hours per month to 26 work-hours per month. This was realised because the construction progress updates were being entered directly into the 3D model (via the AR viewer) and then automatically pushed back to the 4D model being used by the planner. This removed a number of non-value add manual steps from the traditional process.

This trial demonstrated the potential value of AR to construction but also highlighted that there are numerous factors and considerations that currently limit its suitability for large scale deployment .

Additional use cases were identified during the DFSS initial definition workshops by the project team and are listed below. There was no time to extensively implement these use cases during this trial but they should be considered for future implementations of AR.- Stakeholder visualisation using 2D or 3D models

- 4D field driven project planning: The 3D construction sequencing model is overlaid against the real-world site environment so the construction sequence can be checked and verified on site

- Safety viewer: Specific safety or hazards can be augmented over the real-world site environment using 3D pop-up icons

- Project Technical Requests viewer: Non-conformance or Requests for Information (RFIs) can be augmented over the real-world site environment using 3D pop-up icons

- Drawing access: 2D/3D virtual blueprints accessed on site

- Systems training / Operations & Maintenance: Systems operations & maintenance information overlaid over the installed equipment on site to facilitate familiarisation of systems during handover and operations & maintenance.

Recommendations for Future Projects

Technology advancement within the AR industry is rapid with more capable products are being released on a regular basis. Given the size and number of technology companies investing in the AR industry it is certainly a technology that will deliver benefit to Construction within the near to mid-term (2-5 years).

This pilot demonstrated a very small area that AR can benefit but it would seem that AR has much wider potential for use in Construction. Therefore it is recommended that the use of the technology continues, focusing on the potential use cases outlined in the lessons learned section above.

The following technical considerations and limitations were identified during the trial and should be considered for future deployments of AR solutions:- Business logic challenges: How the data to be loaded, or streamed, to the AR device is managed in the backend content management system. This needs to be well automated if the AR solution is to scale for widespread use.

- Complexity and capabilities of tracking technology: the augmented data needs to be positioned correctly and remain stable as the user moves. Some tracking technologies were not suitable for displaying 3D models.

- Positional accuracy: mobile (iPad) apps currently do not provide the sub-millimetre accuracy required for some use cases.

- Human interface issues: need for use to wear PPE, limitation on construction certification for wearable devices (e.g. Google Glass)

A further analysis of the potential for use of AR in Construction in the ICE paper “Will Augmented Reality in construction deliver on its promise?” by the same author is included below.

-

Document Links

-

Will Augmented Reality in Construction Deliver on its Promise

Will Augmented Reality in Construction Deliver on its PromiseICE Paper 19 August 2016

-

-

Authors

Stephen Smith - Bechtel, Crossrail Ltd

Stephen has 20 years of project-based experience working for Bechtel in the US, UK and Middle East on Civil Infrastructure and Telecoms megaprojects. He worked on Crossrail for 4 years as the Information Applications Manager. Stephen is passionate about implementing innovative technology driven work processes that deliver measurable performance improvements on projects. Stephen sits on the Institute of Civil Engineers Information Systems panel and is the Construction Chair of the COMIT (Construction Opportunities for Mobile IT) organisation.

-

Acknowledgements

Marvin Johnson, AR/VR Implementation Manager, Bechtel, Pilot Project Lead