Compliance of Technical Assurance Requirements for MEP Installations at Crossrail Stations, Shafts and Portals

Document

type: Technical Paper

Author:

Wing Fung PhD MSc BSc(Eng) CEng MCIBSE, ICE Publishing

Publication

Date: 30/09/2017

-

Abstract

This paper highlights the approach adopted by Crossrail to demonstrate compliance with technical assurance requirements for MEP installations at stations, shafts and portals. The common approach has taken into consideration the diverse nature of design and complexity of installation at different work sites. The documentation system used was supported by digital information management system (eB) in Crossrail to provide efficient retrieval of information and audit trail.

The technical assurance documentation suite consists of lead assurance documents, compliance certificates and supporting quality documents (backing evidence). They should be complete, adequate and suitable for the purposes of enabling Crossrail to obtain authorisation to enter into passenger service.Key success factors for an effective technical assurance are:

- A good mix between procedural and technical compliance evidence

- A good grasp of the pertinent assurance requirements in particular statutory requirements and industry codes

- A structured line wide documentation system

- Coherent acceptance criteria line wide.

-

Read the full document

Part 1 – Technical Assurance Framework

Evidence-Based System Assurance

System Assurance uses a risk-based approach which is applied from preliminary scheme design activities, through the project lifecycle and into operation. System Assurance works interactively with each Contractor’s during the development of a system in order to provide compliance evidence and arguments timely. The documentation framework is needed to support the Contractor’s practices and to provide confidence to Crossrail. The assurance is deemed to be progressive. Any highlighted deficiencies in the Contractor’s practices or in the evolving evidence are addressed before progressing enabling compliance to the approvals gates for the next lifecycle phase(s). The approach to System Assurance adopted in Crossrail is non-prescriptive in terms of the development process. The assurance requirements are defined such that they can just as effectively be applied to existing systems and to various development lifecycles, subject only to the appropriate evidence being available.

Contractors must address the discipline of System Assurance throughout the lifecycle in terms of both their understanding and approach. If some areas of a project proceed with only a limited awareness of assurance, this will pose an increased risk of time delay, cost overrun and lost performance to the project. Raising awareness and understanding of the importance of System Assurance at all levels in the organisation and across all areas of the project is key to minimising this risk. It is essential that a common framework is established at an early stage in the design process that is both rigorous and consistent across all interfaces.

In addition to the above, Crossrail also undertakes assurance activities to supplement or validate the work of the Contractor. To facilitate these activities the Contractor shall provide access to his facilities, personnel and documentation.

One of the principles that apply to evidence-based System Assurance is that the “burden of proof” rests with the Contractor. It is the Contractor’s responsibility not only to provide assurance arguments as stated in this document but also to show how that evidence supports the associated argument. As the approach to System Assurance is as non-prescriptive as possible, it is the Contractor’s responsibility to justify what he does. Interpretation of terms such as “adequate”, “acceptable” and “appropriate” is left to the Contractor’s judgement initially. However, Crossrail’s interpretation shall prevail whenever the Contractor’s interpretation presents an unacceptable risk to the project. Furthermore, all evidence must be documented in a way that allows it to be inspected. Activities which are undertaken during the development which do not lead to documented output cannot provide any valid form of evidence unless specific alternative forms of evidence are proposed by the Contractor and agreed by the Crossrail System Assurance Manager.

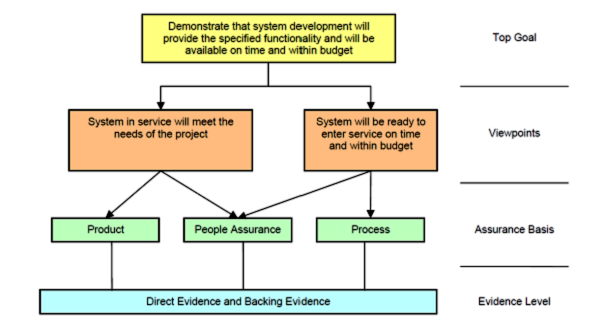

The System Assurance framework adopted for MEP installations at stations shafts and portals is presented in Figure 1. The main goal of System Assurance is to demonstrate that the project and the development of individual systems will be successful. In fulfilling this goal, the system should meet the specified user requirements and is fit for its intended purpose. The system should be ready to go into service on time and within budget. This viewpoint is addressed through the Process Assurance and People Assurance requirements.

Figure 1 – System Assurance Framework

Basis of Assurance

Product Assurance addresses the adequacy of the system by ensuring that a complete and consistent set of requirements are specified and that these requirements are fully satisfied in the delivered system. Demonstrate that system development provides the specified functionality and is available on time, within budget and meets the needs of the project.

Product Assurance is required for all systems irrespective of their previous history and maturity. Arguments and evidence may be obtained from an appropriate combination of field-service experience of existing (or sufficiently similar) products, analysis of the system, and testing of the system.

Process Assurance ensures that the Supplier has an acceptable set of management processes in place to support the development and monitors adherence to these processes.

Process Assurance is required to some extent for all systems but the scope of its application will depend on both the assessed development risk that the system presents to the project timescales and/or costs. Arguments and evidence shall be obtained from the processes used in the development of the system.People Assurance ensures that all Supplier staff are competent to undertake the Product and Process Assurance tasks for which they are responsible. People Assurance is required for all systems irrespective of their previous history and maturity. Arguments and evidence shall be obtained from the processes used in the development of the project.

This paper focuses on the product (and service) aspects of the project. Process and people aspects of the projects are dealt with in the quality assurance regime.Evidence Level

For each assurance objective and corresponding lower-level arguments, evidence is required in two forms:

- Direct Evidence- The term for an item of evidence that is a direct output of undertaking an assessment, development or testing activity. The existence of this evidence provides confidence that the activity has taken place. Examples of Direct Evidence are requirements specifications; design documentation; and test specifications, plans and results.

- Backing Evidence- The term used for an item of evidence that provides confidence that an item of Direct Evidence is credible, soundly based and trustworthy. It is based usually on the adequacy and competent application of the process which gave rise to the Direct Evidence. Examples of Backing Evidence are evidence of the effective review of requirements, design, testing and commissioning documentation; results of verification activities used to demonstrate the adequacy of the decomposition of the design; and confirmation that staff have been subject to competency reviews.

Technical Assurance

Within the range of assurance requirement covered by the Integrated Assurance and Approval Plan (IAAP)[1] , Technical Assurance covers the technical functionalities of the project deliverables. In the context of MEP installations in stations shafts and portals, it refers to the performance of the installations and their interaction with other railways system installations. To put the system at work, there is a need to assign a technical authority to oversee the successfully implementation of technical assurance plan. The Chief Engineer Group is the Technical Authority for Crossrail.

Part 2 of this paper highlights the scope of assurance evidence required for the MEP installations at the Crossrail stations shafts and portals. The documentation framework presented help illustrate the implementation of technical assurance plan for Crossrail.

Part 2 – Technical Assurance Evidence for MEP Plant in Stations Shafts and Portals

In Part 2 of this paper, the mechanical, electrical and public heath (MEP) installations at stations, shafts and portals are used to illustrate how the Crossrail line wide technical assurance regime is put at work.

Figure 2 describes how the technical assurance data are captured and assimilated during the design, construction and verification/ validation stages in the project life cycle. Throughout these stages, the Contractors are required to provide assurance evidence in a progressive manner to demonstrate compliance with performance requirements as set out in the project brief. These documents are kept electronically in the centralized ‘eB’ documentation system under the respective category for ease of retrieval and cataloguing. In general, there are three main categories of assurance documents:

- Technical related assurance documents

- Process or procedure related assurance documents

- Verification and Validation related documents

Figure 2 – Flow diagram illustrating how assurance data are captured

and assimilated in the project life cycleTable 1 provides the range of assurance evidence that Crossrail will expect from the Contractors for the MEP installations.

Table 1– Categories of assurance evidences to be provided for MEP installations

Technical Assurance Process Assurance- system engineering Design Statement Requirement Compliance Basis of Design Systems Integration Design Completion Certificate Risk Assessment General Arrangements Drawings Project Wide hazard register Schematic Drawings Quality Plan Section Drawings Access and maintainability Detail Drawings Reliability, Availability, Maintenance and Safety Equipment Schedules / Data Sheets EMC Control Description of Operation and Control EMC Design Review and Hazard Analysis Compliance with Building Regulation Engineering Safety Management Water Regulation approvals Earthing Management Plan Sewer connection approval BREEAM / CEEQUAL Fire Alarm and Detection- Cause and Effect Matrix EMC Survey Fire Engineering Fire Strategy Human Factors Calculations Plant replacement strategy drawings Room Data Sheets Approved concessions for non-compliant Materials Compliance Schedule Process Assurance- design and construction management Materials and Workmanship Specifications Design and Construction Programme Building Management System Design Master Delivery List Lighting Control Design Testing and Commissioning Plan / Strategy UPS and Battery Design CDM Register Internal Acoustic Project Risk Register Noise from Fixed Installations Interface Management Public Address/ Voice Alarm Acoustic Model Interface Control Metering Strategy Competence Management Verification and Validation T&C records VAP reports against high risk items VAP reports on integration of systems on design and construction The above exercise generates a large volume of assurance evidence in the assurance database. While they provide valuable information on technical and procedural compliance with project requirements, not all information are relevant to the handover deliverables of the project. Towards the handing over of MEP installations, there is a need to present technical assurance case for MEP installations. To facilitate this, the relevant assurance evidences are identified and grouped into the following three categories:

- Lead Assurance Documents.

- Compliance Evidence.

- Supporting Quality Documents.

The following sections provide in further details what is contained in the three classes documents for mechanical, electrical and public health installations for stations, shafts and portals in Crossrail.

Key success factors for an effective technical assurance regime are:

- A good mix between procedural and technical compliance evidence

- A good grasp of the pertinent assurance requirements in particular statutory requirements and industry codes

- A structured line wide documentation system

- Coherent acceptance criteria line wide.

Lead Assurance Documents

The lead assurance documents will provide evidence to which confirm that the prescribed specific performance criteria are met. The lead assurance documents are reviewed and endorsed by the assigned assurance engineer(s) of Crossrail for the respective engineering disciplines. A list of the lead documents for the MEP installations is shown in Table 2.

Table 2– List of Lead Assurance Documents

Category Lead Assurance Document Compliance with Functional Requirement Requirement Compliance Report Design/ installation Compliance Acceptance Certificates for engineering installations Validation and Verification Testing and Commissioning Reports; VAP- Design and Construction System Safety System Safety Compliance Report Systems Integration Integration Tests Report; VAP- Systems Integration Human Factors Human Factors Compliance Report EMC/ Earthing and Bonding EMC/ Earthing and Bonding Compliance Report Reliability Availability and Maintainability RAM Demonstration Report Environmental and Sustainability D25 Breakout Noise Compliance Report; BREEAM/ CEEQUAL Assessment Report Operation Readiness Railway and Station Operation Procedures; Operation and Maintenance Manuals; Training of Operations/ Maintainers; Spares Compliance Certificates

Table 3 provides a list of compliance certificates that are required for the MEP installations to satisfy statutory requirements. The set of certificates has to be complete, adequate and suitable for the purposes of enabling Crossrail to obtain authorisation to enter into passenger service.

Table 3– List of Assurance Certificates

Category Description of Certificate Conformity to construction management procedures Factory Acceptance Test Certificate (FAT); Installation Release Notice (IRN); Pre-Commissioning Certificate (PCC); Partial Acceptance Certificate (PAC); Acceptance Certificate (AC); Warranty Certificate Conformity to technical standards Conformity Certificate for MCC; Compliance Certificate for fire rated air ducts and support bracketry; Compliance Certificate on corrosion protection measures; Welding Test Certificates; Certificate of Conformity for Pressurisation Systems; Conformity Certificate for main Switchboards; Electrical Installation Certificate as required by BS767; Certificate of fire safety system as required under BS5839; Certificate of Conformity of fire stops; Completion Certificate for water mist system; Completion Certificate for gas suppression systems; EMC Conformity Certificate for service critical panels; System safety and integrity test- Form 45 inspection for escalators; System safety and integrity test- Form 54 inspection for lifts Conformity to Building Regulations Certificate which states that the completed work complies with specific sections of building regulations Notified Body Certificates Declaration that the fixed installation meets the essential requirements of EC TSI Directives Conformity to Environmental and Sustainability Requirements IPD25 Certificate of Compliance for break out noise; BREEAM/ CEEQUAL Assessment Supporting Quality Documents

Supporting quality documents or backing evidence (as sets out in Table 4) is the part of the database that will supply the evidence for the lead assurance documents and compliance certificates. Each work package will have its own list of documents pertaining to the nature of work, work scope and complexity.

Table 4– List of Supporting Documents

Category Description of Document Design/ installation Compliance Specification; Final Design Drawings; Construction Drawings; As built drawings; Equipment Schedule; Schematics; Material Compliance Records; Compliance Certificates of products/ installations; Safety Certificates of installations Testing and Commissioning Reports Systems Commissioning Logics per Elementary Systems; Systems Breakdown and Identification; Systems Commissioning Schedules

T&C Work Programme; T&C Strategy; T&C Plans; Commissioning Manuals; Commissioning Lots Definition Documents; Manufacturing Inspection and Test Plans (ITPs) and associated record forms of sheets; T&C Process Procedures (IRN, WAD, Punch List, Room Access); Test Descriptions and associated Test Data Sheets including Acceptance Criteria; IRN Register & Associated Progress Key Performance Indicators (KPI); PCC, PAC, AC Register and associated progress KPIs; WAD Register; T&C Phasing and Certification; Self-certification of T&C Works Procedure; Certification of T&C Personnel

Test Tools Calibration Procedure; T&C Certificates; Typical Format for Test Procedure; Test Descriptions; Test Plans; Interface Management Plan; Interface Control Document (Design); Interface Control Document (Construction)

Functional Requirements Supporting documents as stipulated in the Compliance Report Human Factors Supporting documents as stipulated in the Compliance Report EMC Supporting documents as stipulated in the Compliance Report System Safety Site Assurance Files (or similar record packages) production; Power Supply Safety Rules; Mechanical Safety Rules RAM Fault Reporting and Corrective Action System Records; Early maintenance of Systems until Handover Operation Procedures Supporting documents as stipulated in the Procedures O&M Manuals Supporting documents as stipulated in the Manuals; Asset Lists Training of Operations/ Maintainers RAM System Analysis; Maintainability Report; Training Needs Analysis; Training Course Material & Attendance Lists Spares Reliability Availability and Maintainability System Analysis; Maintainability Report; List of spares Systems Integration Management Systems Integration Management Plan; Systems Integration; Architecture; Systems Interface Matrix and nodal points; List of key systems integration documents; Competency of Systems Integration staff; Progress Report; Surveillance Report; Audit Report Building Regulations Supporting documents referred to in the Compliance Report BREEAM/ CEEQUAL Supporting documents referred to in the Assessment Report and Pre-assessment Report Conclusion

An effective and systematic approach to capture and assimilate assurance data is an important part of project management procedure to demonstrate compliance with project requirements. Maintaining a consistent and coherent documentation framework is particularly a challenge to multi-disciplinary project where a large number of discrete work packages are working in tandem towards a set of common performance requirements. In this paper, the data processing framework developed for MEP installation is used to illustrate how the technical assurance regime of Crossrail is put to work.

Ability of the technical assurance regime to maintain a good collection of documents that covers all the pertinent assurance requirements is of paramount importance in this context.

References

[1] HM Treasury, Integrated Assurance & Approval Strategy and Integrated Assurance & Approval Plans- A guide to implementing integrated assurance and approvals, Cabinet Office, 2011

[2] A Design Framework for Building Services, 3rd edition BSRIA, 2012 -

Authors

Wing Fung PhD MSc BSc(Eng) CEng MCIBSE - Arcadis

Technical Director (MEP), Arcadis

Wing is is a Chartered Engineer with over 30 years’ experience as a technical specialist engaged in mass transit system planning, design, project management, technical assurance, commissioning, energy management, operation and maintenance, and asset renewal. Wing has been with the Crossrail project in the CRL Chief Engineer Group since 2013, overseeing mechanical design, systems integration and T&C.

Specialties: Building Services, Mechanical Engineering, Computational Fluid Dynamics, RAM studies, Systems Integration, Requirement Management, Testing and Commissioning.