Crossrail Systems Integration – Lessons Learned and Good Practice in Managing Interdisciplinary Systems Integration through each Stage of the Crossrail Programme

Document

type: Technical Paper

Author:

Derek Tyner BEng(Hons) MIET CEng

Publication

Date: 02/12/2021

-

Abstract

This paper sets out the main observations and lessons learnt about the integration of many different systems and the interdisciplinary coordination activities as taken from the Chief Engineers Group experience of the Crossrail Programme and highlights a strategy for Systems Integration that could be applied on other Mega Projects.

These multiple systems and sub-systems have been brought together and proven to work together in a fully integrated way during the course of the works programme. This process of systems integration needed to be managed effectively from the earliest stages of outline Design through all the Installation and Testing stages right up to Handover. There was not sufficiently detailed information provided in the original Works Information on the requirements and responsibilities for integration activities. This information had to be developed and instructed later in the Design Phase.

To achieve the ultimate goal of full integration at the point of handover of the infrastructure to the end-user it is important that a dedicated, central team is put in place at the very start of the programme with responsibility to actively manage the System Integration activities that must be carried out by the Contractors and their Designers, Manufacturers, Installers, Test and Commissioning teams.

-

Read the full document

Introduction

The Crossrail Programme has provided London with a new, transformational railway running east to west across the city and connecting into the existing Eastern and Western railway networks. The scale and complexity of the Crossrail works required the integration into a functional whole of many separate systems and sub-systems. These systems have been designed using many different technical disciplines but were each required to function in unison with many other types of systems.

The precise and methodical integration of these systems was vital to the functional performance of the completed Elizabeth Line railway to ensure the required levels of safety, reliability, security and energy efficiency were achieved. The operator of the railway rightly expects these various systems to perform seamlessly and in concert to deliver the optimum overall performance of the whole infrastructure. During the course of the Crossrail Programme many of these systems were continually developing to become more technologically complex and interactive. These systems were generally designed, developed and installed by dedicated teams who specialise in one particular system-type but who may have had limited knowledge or experience of the other interfacing systems that were also being delivered by other Designers, Contractors and Sub-Contractors. Bringing together these many different contributors to integrate all of the various systems together was a major challenge throughout the Crossrail Programme.

Integration of Systems

These multiple systems and sub-systems needed to be brought together and proven to work in a fully integrated way during the course of the Crossrail Works programme. The vast size and long timescale of the programme made it extremely difficult at the outset to predict and plan for all the required integration activities that would be required to achieve the integration goal. This is a common feature of many Major Infrastructure Programmes that are carried out over extended durations where technical developments and the evolution of designs alter and expand the quantity and complexity of the system integration tasks required to be completed.

The Crossrail Works Information outlined the overall strategy for systems integration for each Contractor Team, whether Tier1 or Routeway Systems. But this was the high level information, and there was not the detailed schedules of actions, responsibilities and deliverables available at Contract award. This is not in anyway unusual for a mega project like Crossrail, due in part to the immature state of the Employers Design in the early stages of the project and also because of the inherently high level of uncertainty that exists at that stage. In short, it is impossible to plan for everything on a mega project.

The intention was that each Contractor would fully develop their own systems integration scope in parallel with their Design Development. As the Design phase of the works progressed it was observed by the Chief Engineers Group (CEG) and the Testing and Commissioning Team, that each of the Contractors’ had different levels of expertise and understanding of the scale and complexity of the systems integration works that they would be required to carry out. That realisation triggered concerns within Crossrail about how effective the co-ordination and completion of the integration works would be throughout the various stages of the works.

It was then identified that Systems Integration needed to be managed effectively from the earliest stages of outline Design through all the Installation and Testing stages right up to Handover, if the completed infrastructure is to deliver the required overall levels of performance. As the works had already reached an advanced stage of Design maturity by this time, CEG were tasked with drafting a set of additional guidance documents, for issue to all Contractors, that would detail more clearly the activities and responsibilities required to enable them to plan and co-ordinate the systems integration works.

This was a major change in posture by Crossrail from that which was originally envisaged. Instead of Crossrail adopting a laissez-faire approach to systems integration where CEG expected the various parties to work up the details for themselves, as was the initial position at Contract Award, CEG then pivoted to a far more engaged and proactive stance by drafting and issuing to the Contractors specific guidance notes on the integration activities required for a wide range of key systems and the interconnected equipment.

A key lesson that was learnt is that to achieve this ultimate goal of integration at the point of handover of the infrastructure to the end-user it is imperative that a dedicated team is put in place at the very start of the programme with responsibility to actively manage the System Integration activities that must be carried out by the Designers, Manufacturers, Installers, Test and Commissioning teams. These Systems Integration activities must be set out as a clear set of Requirements within the Works Information for each of the Designers and Contractors involved in the Programme of Works. The responsibilities of all parties, and their interfacing parties, must be clearly defined at each stage of the Works, such that the integration activities can be progressively reviewed and assessed against these Requirements by the Systems Integration team.

The progress of each Designer and Contractor in completing their Systems Integration Requirements should then be periodically checked in the same way that compliance with Functional Requirements, Undertakings and Safety Requirements are reviewed as the works proceed, e.g., using Design Reviews, Gate Panel Reviews, Interim Design Overviews (IDO), Final Design Overviews (FDO) and the Systems Integration Review Panel. This will give a dynamic metric to the Programme Delivery Team and to the Client’s Technical Authority Team of how effectively the Systems Integration activities are being implemented at any point in time and will provide opportunities for intervention by the Systems Integration team if progress is not satisfactory and additional guidance is required.

For major works programmes such as Crossrail, Systems Integration is the process to coordinate a group of networks, or systems, to function as one seamless entity on an infrastructure project. This process brings together the component subsystems into one system and ensures that the subsystem function supports the overall system requirements both physically and functionally to act as a coordinated whole. Refer to Crossrail Technical Paper “Integration, Testing and Commissioning At Crossrail”[1] for details of the Routeway and Rolling Stock integration arrangements.

All major infrastructure programmes involve the combination of many different systems and sub-systems into a coherent and reliable set of assets that delivers optimum performance safely and securely. It is not sufficient that these many and disparate systems only work effectively to deliver their own primary functionality. It is just as important that these multiple systems also work in an integrated and coherent way with each other to maximise the overall performance of the complete infrastructure. The systems and subsystems that comprise the infrastructure interact with each other across interfaces, and these interfaces are defined as a shared boundary or connection between two dissimilar systems through which a function is passed. The connection can be physical, functional or protocol.

The challenge of Systems Integration is to achieve the optimum operating configuration of the new infrastructure whereby all the various systems and sub-systems are working together effectively. To meet that challenge it is necessary to plan and manage the Systems Integration activities from day one of the Programme all the way through to completion.

Lessons Learned

Systems Integration is given a high priority in many industries, including the Nuclear, Aerospace and Defence industries, but is sometimes poorly understood in the Construction industry. A primary barrier to incorporating Systems Integration into the key responsibilities of all Contractors and Designers on a typical major construction project is the embedded working practices that have been developed over time may not have prioritised Systems Integration activities. In addition, the frequent changes from one Project to another of the Main Contractor’s partnering arrangements with Designers and Sub-Contractors, who deliver the specialist work tasks and are engaged from a large range of usually smaller companies, has made it more difficult for all these companies to set a standard procedure for implementing Systems Integration activities. This reluctance to fully engage with systems integration activities can lead to some problems during the testing phase of a small scale building project. On a major infrastructure programme, poor Systems Integration management usually leads to more significant problems that extend can extend from the Design and Construction phases and reach into the Commissioning and Handover phases of the programme. Issues with misaligned or incompatible systems are very difficult and expensive to resolve in the late stages of the works and tend to have a major cost and delay impacts on the completion programme.

Why is Systems Integration not usually given a higher priority on major construction projects? It is in part because Systems Integration does not fall neatly under any single Engineering discipline, but rather is an integral feature of every technical field. Also it is hard to measure, it is an intangible concept that is much more obvious by its absence than by its presence.

The main lesson learned from Crossrail on Systems Integration is that for the systems integration activities to be effective, they need to be embedded in the earliest stages of the Programme Scheme Design and to be clearly defined in the Contractual Documents. Then the prescribed Systems Integration activities must be carried out at each Design, Procure, Construct, Install, Test and Commission phase of the works.

Systems Integration is multi-disciplinary by it’s nature and requires a team of Engineers with a wide range of expertise to manage and track it’s progress. However the implementation of Systems Integration is the everyday responsibility of all technical parties within the programme of works, in the same way that Safety is everyone’s responsibility. The inclusion of Systems Integration considerations in all Design, Procurement, Construction, Installation and Testing activities adds significant benefit to the works through the reduction of uncertainty. Any deficiency in these integration activities are likely to lead to additional costs and delays to the programme. Implementation of a robust verification plan to demonstrative effective integration of systems is critical to the success of the project. Table 1 below illustrates the plan so developed for Crossrail.

Scope Description Examples of tests Remarks System Readiness Tests System functions and performance; ‘Internal’ system interfaces System Acceptance Tests;

System function and performance tests;

Safety tests;

Internal interface tests.

T and C within the scope of individual work packages Interface Tests ‘External’ system interfaces System interfaces test Verification of interfaces among work packages in accordance with interface control document. Static Integration Tests (without interactions with train) Scenario tests ‘End to end’ functional and performance tests;

Safety tests;

Stress tests;

Earthing and Bonding tests;

Consolidation of system configuration;

HMI tests;

Access & Maintainability tests;

Cyber security tests.

Mainly related to station MEPF services Dynamic Integration Tests (with interactions with train) Mainly related to routeway services. Trial running Demonstrate integration of engineering systems Normal traffic;

Degraded modes.

Led by the construction team. Trial operation

Demonstrate integration of engineering system and operation protocols Led by the Operation and Maintenance Team. Table 1. Scope of Verification Activities related to systems integration

Recommendations for Future Megaprojects

It is recommended for any future Major Infrastructure Programmes to have a team within the Client’s Programme Partner Organisation that has the Technical Authority to determine and oversee the required Systems Integration activities for all the works, from the initial phase of Contract Formulation right through to Commissioning and Handover.

This body, the Systems Integration Team, should sit within the Technical Directive, rather than the Programme Delivery Team, as it has an oversight role that will span across many individual Contracts, Programme dates and deliverable packages, and so it needs to have the independence and authority to review and challenge the quality and completeness of all Design and Integration document submissions and to witness Integration Testing activities carried out on-site, to assess compliance with the integration requirements.

It is important to note that the system integration responsibilities and activities are actually carried out by the Contractors and their Designers – the clients Systems Integration Team does not take responsibility for carrying out any of the works. The Contractors must retain responsibility to produce and submit the deliverables for review by the Systems Integration Team. At later stages in the programme the Systems Integration Team will need to liaise closely with the Test & Commissioning Team, as the T&C Team have more direct involvement in the Integration Testing activities on site.

The Systems Integration Team should use the Programme’s Technical Assurance regime to progressively measure the performance of the Contractors and Designers against the Systems Integration requirements, in the same way as the Functional Requirements, Undertakings, RAM, ESM, Assumptions, Project Risk, Safety, etc., are continually monitored through each phase of the works on a Major Infrastructure Programme. There is an array of tracking tools available which can provide powerful analytics capabilities of the Systems Integration data and performance metrics. Refer to Crossrail Technical Paper titled “The Railway Integration Approach At Crossrail”[2] for more details of the integration processes implemented.

The Systems Integration Team should comprise a multi-disciplinary group of Engineers with a mix of experience in Systems Engineering, Interfaces, MEP, Comms & Controls, and Testing & Commissioning, so as to have a wide understanding of the primary functions and interfaces associated with all systems and subsystems involved in the works. The Systems Integration team should review systems integration and assurance evidence for the complete project lifecycle from design to fit-out to testing and commissioning to handover phase. The Systems Integration team provides Technical Support to the Contractors and Designers by providing guidance, resolving ambiguous, inadequate or conflicting Works Information and by verifying the outputs progressively for acceptance.

The Systems Integration team can monitor where the Systems interfacing information is not yet available from the Contractors due to lack to design maturity and can put in place appropriate control measures to manage uncertainty risks to the designs and to manage the configuration of potential changes in a systematic manner through the Assurance Process, the Design Reviews and the Design Change Management Process. Refer to Crossrail Technical Paper titled “Integration Tests for Crossrail Station Services”[3] for details of the Integration Test Scenarios and Scripts developed by CEG for issue to the Contractors.

The fundamental requirements for Systems Integration on the Programme should be set out in the following set of documents:

- Systems Integration Strategy

- Systems Integration Requirements Matrix

- Systems Integration Architecture Schematics

- Systems Integration Test Plan

The purpose and contents of these key Systems Integration documents is as follows:

Systems Integration Strategy – The purpose of this document is to describe the approach to be followed through the Systems Integration Team acting as a Technical authority for the acceptance of the System Integration and Assurance outputs through the Contractors works to deliver a fully functioning Integrated Infrastructure that meets the technical and operating requirements.

Systems Integration Requirements Matrix – The purpose of this document is to list out all the integration test requirements against all the interfacing parties and systems. The responsibility of each contractual party to prove systems integration through the successful completion of a range of specific test scripts must be clearly defined, whether that role is to lead the integration testing, or to facilitate and support that test activity needs to be made clear.

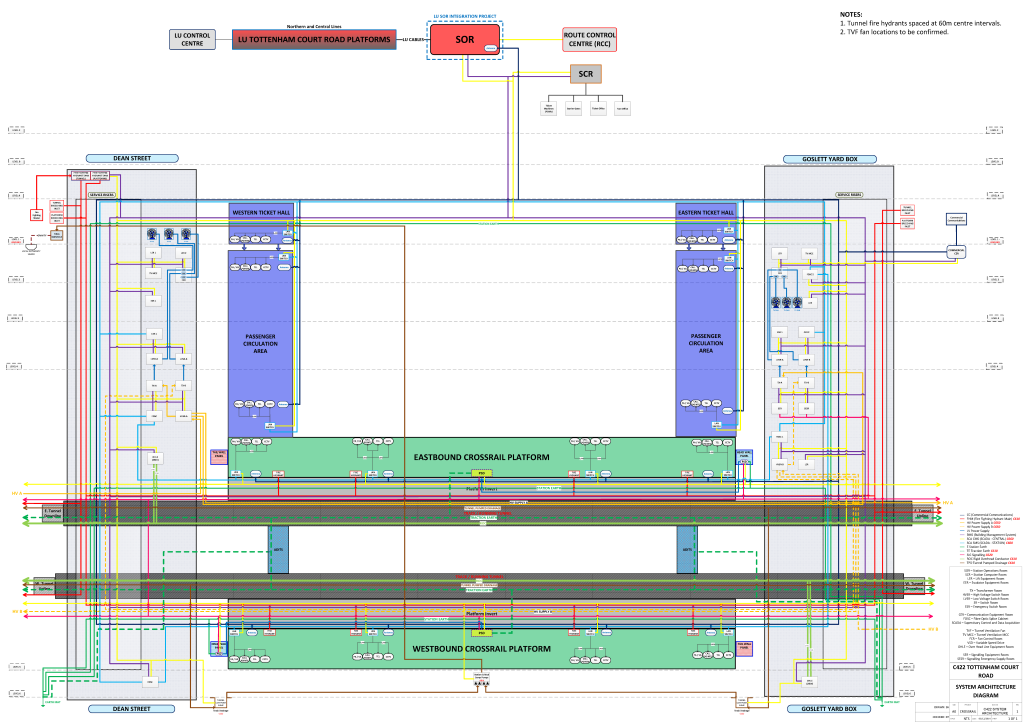

Systems Integration Architecture Schematics – This set of schematics provides a visual overview of the interconnections and interfaces of all systems and sub-systems. These schematics give a high-level representation of the functional inter-dependency of all systems and provide an essential summary of the complexity of the systems integration challenge for any major programme of works. The concept behind these schematics is to identify the high-risk interfaces between the different systems thus providing an integration platform to review, accept and monitor the co-ordination and interfacing works through various Contractors. The interfacing locations identified between the different systems are named Nodal Points (NP) which will be supported by the SIF (Systems Integration Functions).The SIF will be a list of technical data (physical interfaces, functional interfaces, protocols for data exchange etc.) that needs to be captured through the interfacing Contractors in the form of drawings, specifications etc. to support the design alignments, dependencies and sequencing. As part of this work stream the Systems Integration team should clearly identify the roles and responsibilities for the delivery of the systems from both the interfacing parties to support the fit-out phase including T&C and Handover of Assets. It should be the responsibility of the Systems Integration team to develop the set of Systems Integration Architecture Schematics, ready for inclusion into the Works Information.

Figure 1. Example of Systems Integration Architecture Schematic

Systems Integration Test Plan – The Contractors must produce a plan that sets out their systems integration test objectives, activities and certification. This plan should identify the Infrastructure and System Requirements for that Contractor for delivering an integrated and operational asset including its interfaces with other systems and assets within the infrastructure. This SI Test Plan should contain a complete list of each Contractor’ s Integration Testing activities and the roles and responsibilities of all parties involved. These test activities can be detailed out as a Contract-specific set of Test Scripts, derived from the generic set of SI test scripts described above. Each SI test script should contain the test process, output results, testing methods, acceptance criteria and roles and responsibilities of the involved parties.

The Systems Integration Team will review the Contractors and Designers progress against the Systems Integration requirements by periodic review of the following integration and co-ordination deliverables:

- Interface Control Documents (ICDs)

- Detailed Interfaces Specifications (DIRs)

- Combined Services Drawing (CSD)

- Room Data Sheets

- Systems Integration Plan

- Configuration Management Plan

- Commissioning Management Plan

- Verification & Validation Reports

- Co-ordinated Integration Testing Plans

Periodic reviews of these deliverables will provide the SI Team with visibility of the integration works through each phase of the programme.

Conclusion

The main benefit in adopting a concerted approach to Systems Integration is that it mitigates against uncertainty and reduces technical risk. A robust integration strategy helps drive out poor design coordination and installation rework, and avoids testing and commissioning shortcomings. Over the course of the works, this will help to reduce cost and schedule overruns and it lays down a smooth pathway to programme completion and handover.

The second major benefit in bringing Systems Integration expertise to bear onto a programme of works right from the start is that the finished infrastructure will be capable of performing at an optimum level right from handover.

On Major Infrastructure Programmes one of the main causes of operational safety issues, faults, delays, rework and cost and schedule overruns is the failure to successfully manage the integration of the many different, but inter-dependent, systems and sub-systems that make up the whole infrastructure. It is a key benefit to any Programme to have, from the start, a competent and experienced team of Systems Integrators who are able to plan and monitor the required responsibilities and activities that will flag up problems early and enable effective mitigation actions to be put in place in a controlled manner. This will contribute towards efficient and optimised delivery of the Programme of Works.

The Systems Integration resources and processes described in this paper would enable the Mega Project Team to have an accurate and real-time visibility of the interfacing and coordination activities at every stage of the works. This is also a powerful tool in identifying and mitigating against operational and maintenance safety issues that could arise after Handover to the Client, and so will optimise the overall performance of the completed infrastructure.

This will be of importance to the Mega Project Client as it gives them confidence in their Programme and Deliver Partners’ ability to bring together the disparate functions of all the interconnected systems involved in a coherent way that assists in managing uncertainty, with an increase in confidence of costs and the schedule planning for delivery of an integrated and fully functional mega infrastructure asset.

One of the key initiatives for de-risking the delivery of the Programme is to define the strategy for Systems Integration early and to ensure that issues related to Integration during Design, Construction and Testing between different systems, Contractors and Designers wide are systematically planned and executed, using the best information available at each stage in the programme and with the flexibility to control the unplanned and unforeseen issues that may arise during the course of the works.

References

[1] Bhamra S (2018) Integration, Testing and Commissioning at Crossrail – Crossrail Learning Legacy

[2] Bates J and Morris J (2018) The Railway Integration Approach At Crossrail – Crossrail Learning Legacy

[3] Fung W (2018) Integration Tests for Crossrail Station Services – Crossrail Learning Legacy

-

Authors

Derek Tyner BEng(Hons) MIET CEng - Crossrail Ltd, Jacobs

Derek Tyner is the Lead MEP (Mechanical, Electrical and Public Health) Engineer for the Crossrail Chief Engineers Group. He is responsible for programme wide Technical Assurance activities covering all Stations, Shafts and Portals and Linewide MEP Systems. He manages a team of highly experienced MEP Engineers who perform the assurance reviews of all Contractors MEP design and installation works. Derek has worked for 30 years in the Engineering and Construction industry, the last 20 years exclusively on major rail infrastructure projects. Derek has worked on Crossrail, in the Chief Engineers Group, since 2009.