Crossrail’s Approach to Health and Safety Assurance Assessment

Document

type: Micro-report

Author:

Steve Mullins

Publication

Date: 27/09/2016

-

Abstract

Health and safety assurance assessments allowed the Crossrail H&S assurance team to react to evolving issues with a flexible assessment outside of the formal audit programme. Some assurance assessments were tightly focused on specific contracts’ emerging issues, whilst others were programme-wide, where issues affected a wide range of the contracts. High levels of collaboration were evident from all of the project contractors and other stakeholders.

This paper should be of interest to Health and safety assurance specialists and any project looking to develop their approach to health and safety assurance. -

Read the full document

Crossrail’s Approach to Health & Safety Assurance Assessment

Health and safety (H&S) assurance is a key driver of the effective implementation of health and safety management systems. Organisations like Crossrail utilise H&S assurance to:

- Provide confidence that internal and external organisations, services or products meet specified health and safety requirements

- Identify the need for intervention when health and safety requirements are not met or are unlikely to be met.

Effective H&S assurance emphasises the need to understand people’s behaviours and the incentives and disincentives that may lead to unintended consequences, through encouraging inappropriate behaviour.

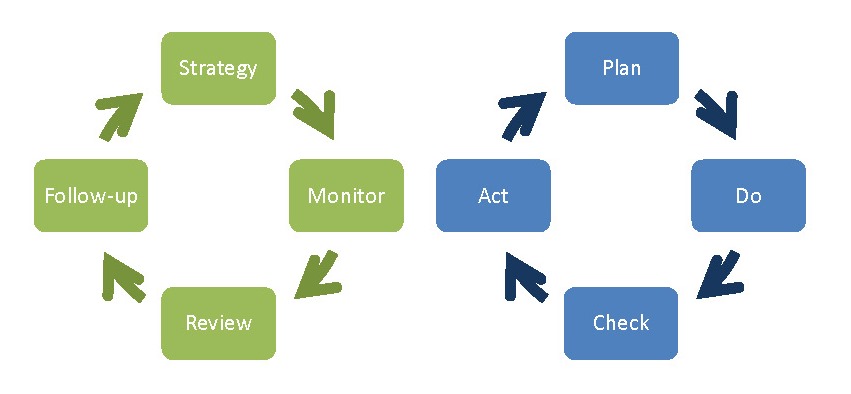

The Crossrail H&S assurance model ‘Strategy – Monitor – Review – Follow-up’ parallels the Deming (or Shewhart) Cycle ‘Plan – Do – Check (or Study) – Act’ model of management systems[1]. H&S assurance and effective safety management are interdependent.

Figure 1 – Crossrail’s Assurance Model (Left) and the Deming Cycle (Right)

Assurance Process

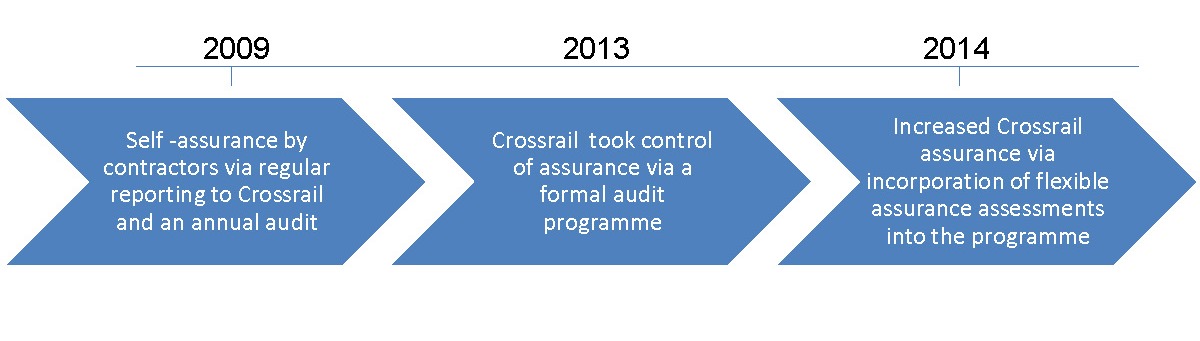

Crossrail’s H&S assurance processes have grown and evolved through the progress of the project. When the project started construction in May 2009, assurance activities were ‘light touch’ with each contractor providing self-assurance on their management of H&S at their projects, by regular submission of assurance questionnaires; backed up by a single H&S audit per project per annum.

Crossrail recognised that the ‘light touch’ approach was not always delivering sufficient confidence in the contractors’ health and safety management, as there was a perceived reluctance to raise issues (non-conformances) against themselves with an average of one corrective action request (CAR) raised per period across the entire programme.

In 2013, Crossrail revised their H&S assurance programme, and implemented a comprehensive assurance audit schedule covering the then 23 contracts/sites. The Crossrail area directors and project managers formally agreed this audit schedule with the H&S assurance team. The audit schedule was designed around the H&S risks presented at each project by their processes, locations and/or interfaces. The H&S assurance team decided upon 14 H&S topics based on these risk profiles. The schedule was then designed to include six tightly focused audits per contractor, per annum.

However, the tightly focused and pre-planned nature of the Crossrail H&S assurance audit programme did not always provide the H&S assurance team the flexibility to respond to evolving issues on either a local contract, or programme-wide basis. Crossrail developed an H&S assurance assessment process to address this deficiency. H&S assurance assessments reflected the overall aims of the audit programme but were less formalised, and could be narrowly focused like an audit, or more widely focused to address programme wide issues.

Figure 2 – Assurance process timeline

The head of H&S assurance would agree a scope with the assurance team when evolving trends were identified, then the team would carry out the assurance assessments in collaboration with the appropriate project contractors and other stakeholders.

Crossrail would undertake assurance assessments in response to:

- An accident/incident/near miss for which the root cause may be evident on other contracts/sites

- An emerging Health and Safety risk or change in legislation

- A request from the Health and Safety Director, or the Programme Area Director

- One or more audit findings which may require investigation on a wider basis

Assurance Assessments Positive Consequences

Assurance assessments were identified for a range of issues. These often focused on key risks identified during audits and Crossrail’s on site H&S activities. Construction Railways and Fire Safety were two significant assessments undertaken.

Construction Railways

In 2013 a key focus of the H&S assurance team was construction railways. After a thorough review of the hazards involved, together with the near miss and incident reports received, Crossrail decided to undertake an H&S assurance assessment on both the management of tunnel rolling stock and on tunnel railways track maintenance. These were carried out in collaboration with the principal contractors of the three tunnel drive contracts due to the commonality of equipment, work environments and incidents. The three tunnelling contractors were actively engaged in both the scoping of the assurance assessments, and in its implementation through regular meetings, inspections and in-depth discussion prior to reporting the findings.

The H&S assessment reports identified a number of good practices but also a number of opportunities for improvement in the management of construction railways. The work undertaken by all of the contractors and the Crossrail H&S teams to address the issues identified led directly to the foundation of a programme wide working group which developed and published Crossrail’s Best Practice Guide – Construction Railways’. As well as being implemented across all Crossrail sites, this document has been recognised by the British Tunnelling Association (BTA) and International Tunnelling Society (ITS) as the best framework to manage construction railways, and consequently shared globally.

Fire Safety

As with all major construction projects, fire presented a risk for Crossrail; not just due to the size and scope of the project itself, but also with its location within central London and its many interfaces with other major infrastructure assets such as London Underground and Network Rail. Crossrail managed fire safety assurance by undertaking a rolling programme of assurance assessments with the Crossrail London Fire Brigade (LFB) liaison officer in conjunction with the H&S assurance team. Integrated into the Crossrail H&S audit schedule, the fire assurance assessments pro-actively checked both legislative requirements and the London Fire Brigade’s requirements for fire-fighting provisions. A future learning legacy paper will detail this how this LFB collaboration worked.

Collaboration

The engagement and collaboration of the project principal contractors with the LFB and the H&S assurance team (including regular meeting, joint inspections and open discussion of issues) ensured that all of the contractors were compliant with legislative requirements and LFB fire-fighting provisions were in place and properly maintained. Essentially the risk to people on site was reduced and Crossrail’s assets were protected.

The collaboration between Crossrail, the LFB, the Fire Protection Association (FPA), Construction Industry Publications (CIP) and the project principal contractors on fire safety led directly to the publication of the ‘Construction Site – Fire Safety’ Best Practice Guide’.

Lessons Learned and Recommendations

The assurance assessment process has been an evolving process. It relies on a high degree of collaboration with the project principal contractors. Where this was not evident, recommendations were not actioned in a timely manner and the output was less effective. Unlike the Crossrail audit process where non-compliance results in the generation of a formal Corrective Action Request (a time limited action plan to address the non-compliance was agreed with the auditee), assurance assessment recommendations are reported, but actions to close are not subject to a deadline for action, and progress was not formally tracked. This has been identified as a weakness. For future assessments and for future projects it is recommended that a formal tracking and closure mechanism be agreed for assessment finding with the contractors to ensure that issues are suitably addressed in a timely manner.

References

[1] Deming Cycle – W Edwards Deming ‘Out of the crisis’ 1982-86

-

Authors

Steve Mullins - Crossrail Ltd

Steve Mullins is a Health and Safety Specialist in the H&S Assurance team who joined Crossrail in February 2015. Prior to Crossrail Steve worked extensively in Construction, Engineering, Built Environment and Infrastructure H&S, including the Rail and Airport sectors. He is responsible for conducting contractor Health and Safety Assurance activities, including audit and assessment. Steve is also responsible for stakeholders assurance via the RISQS and Sentinel processes