Door Forces in Underground Infrastructure

Document

type: Technical Paper

Author:

Dr Fathi Tarada BSc LLB MBA DPhil CEng FIMechE FIFireE FICE

Publication

Date: 02/12/2021

-

Abstract

During the course of commissioning the Crossrail stations, it was observed that a wide range of forces was required to open these doors, some of which appeared to be excessive.

Within the stations, certain door opening forces were significantly influenced by the pressures induced by the tunnel ventilation and shaft pressurisation systems, which operate independently. This paper reviews the opening forces measured at evacuation and intervention doors within the Crossrail stations and shafts, presents the requirements currently adopted by the Crossrail project, and outlines the standards and guidelines relevant for such doors. The legal requirements pertaining to the safety functions of evacuation doors are briefly presented, and analysis is presented of the physiological data pertaining to individuals’ pushing strength.

The paper sets recommendations for the maximum allowable opening forces on doors within evacuation and intervention routes impacted by the tunnel ventilation system, which were agreed through peer review.

-

Read the full document

1 Introduction

Mass rail transport systems, including the eight Crossrail underground stations, do not generally have doors located on the main passenger circulation routes. This is to facilitate the movement of people and to avoid the presence of any bottlenecks. However, a large number of doors have been installed within the Crossrail underground stations away from the main passenger circulation routes, ranging from 659 doors for Liverpool Street, to 215 doors for Woolwich. These doors are provided in the following locations:

- Operational rooms, including station control rooms, staff mess areas, staff toilets and staff locker rooms. These are rooms which are designed for general daily use by staff members.

- Plant rooms, including rooms containing HV and LV transformers, sewage pumps and fire main valves and air handling equipment. Access to these rooms is infrequent and limited to maintenance and replacement activities.

- Public areas, including lobbies to staircases and disabled refuges (“front-of-house” doors).

This paper focus on doors installed in public areas, rather than “back-of-house” doors. Such “front-of-house” doors serve a safety function, namely to facilitate evacuation to a place of safety, in case of fire or other emergency. As such, it is important to ensure that these doors are readily openable by the evacuees themselves or by station staff who may be assisting them. In opening the doors, users may have to overcome pressures generated by the operation of smoke extraction fans, as well as the resistance due to mechanical door closers, door hinges and the weight of the door itself. It is therefore important to set acceptable limits to the opening door forces, so that evacuation through these doors is not compromised.

2 Industry Context

2.1 Door Forces Specified in Contemporaneous London Rail Projects

Guidance from contemporaneous London rail projects on maximum allowable door opening forces is provided below. Although all these projects have referred to the DTI report[1] in their proposals, they have all interpreted the data somewhat differently. None of these projects have considered the wide scatter observed in the strength values reported by the DTI. The reports listed below have been approved by the relevant project teams, and have been tacitly accepted by the London Fire Brigade.

2.2 TfL – Victoria Underground Station

Report VBN-V047-1159-GEN-DOC-000010, “NTH SF001 & SF002 Stair Pressurisation Technical Note, Door Forces and Differential Area Pressure”, 21-09-2017[2] states that a maximum door-opening force of 240 N for a pressurised staircase is deemed acceptable, based on average strengths measured in the DTI report.

2.3 Bank Station Upgrade Programme

Report SPG-VCP-RPT-BNK-007-R01, DLR Fire Door Opening Force Evaluation, 15/05/2018[3] states that a 285N door opening force with tunnel ventilation system operating is deemed acceptable, based on average strengths recorded in the DTI data.

2.4 Northern Line Extension Project

The report MMD-N001-2360000-GEN-MEM-00003 Technical Note – Assessment of Door Opening Force, 28/02/2017[4] proposes a 250N door opening force criterion at base of shafts, and 180N at cross-passages, based on DTI data.

3 Requirements from Standards and Guidelines

3.1 BS 9992:2020, “Fire safety in the design, management and use of rail infrastructure — Code of practice”[5]

Section 18.2.1(d) of BS 9992:2020 requires that the design of the pressurization systems serving firefighting shafts should be coordinated with the design of any other smoke ventilation systems, e.g. tunnel ventilation systems that serve adjacent areas, in order to ensure that the combined pressure differentials do not result in excessive door opening forces. The maximum allowable door opening forces are set by reference to section 27.1.3 of BS 9999:2017 (100N for doors in fire-fighting shafts) and in section 28.5 of BS 9992:2020 (220N for cross-passage doors).

3.2 TfL’s S1067 – Tunnel and public area cooling and ventilation[6]

TfL’s S1067 standard states that maximum pressures applied to pressurised stairs, lift shafts, and lobbies, are limited by maximum allowable door opening forces. By reference to BS EN 12101-6[7], S1067 states that the system shall be designed so that the force on the door handle, required to open it, shall not exceed 100N. For a variety of reasons e.g. self weight of the fire door, this may not always be achievable. In such circumstances, the S1067 standard states that data from the DTI strength data for design safety[1] may be used to justify a reasonable departure in excess of this maximum requirement.

3.3 NFPA 130 – Standard for Fixed Guideway Transit and Passenger Rail Systems, 2020 edition[8]

NFPA-130 is an international standard which specifies fire protection and life safety requirements for underground, surface, and elevated fixed guideway transit and passenger rail systems. It is widely used in North American, Asian and Middle Eastern railways, including the Singapore and Hong Kong mass transit systems. The first edition of NFPA-130 was issued in 1983, and the latest edition was issued in 2020.

Paragraph 6.3.3.12 of the NFPA-130 standard states:

“Doors in the means of egress shall comply with the following:

-

- Open fully when a force not exceeding 220N (50 lb) is applied to the latch side of the door

- Be adequate to withstand positive and negative pressures caused by passing trains and the emergency ventilation system”.

3.4 BS 8300-2:2018, “Design of an accessible and inclusive built environment. Buildings. Code of practice”[9]

BS 8300 states that:

“For most disabled people to have independent access through single or double swing doors, the opening force, when measured at the leading edge of the door, should be not more than 30N from 0° (the door in the closed position) to 30° open, and not more than 22.5N from 30° to 60° of the opening cycle. The opening force should be checked using a plunger‑type force measuring instrument”.

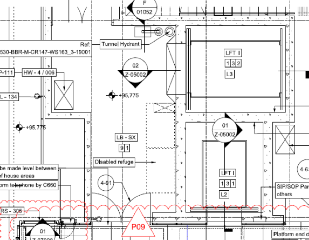

Figure 1. Woolwich Station – Platform Disabled Refuge (West End)

3.5 ITA-COSUF report on “Current practice on cross-passage design to support safety in rail and metro tunnels”[10]

ITA-COSUF has published a report on international best practice in the design or cross-passages in rail and metro tunnels. The ITA-COSUF report refers to the NFPA 130[8] guidance on the maximum opening force for swing or sliding doors of 220N, and to the Swiss railway standard[11] which sets 100N as the maximum opening force for sliding doors.

4 Legal Obligations

4.1 Legislation

The Railways and Other Guided Transport Systems (Safety) Regulations 2006

The Railways and Other Guided Transport Systems (Safety) Regulations 2006 (ROGS) provide the regulatory regime for rail safety, including the mainline railway, metros (including London Underground), tramways, light rail and heritage railways. ROGS will apply to the operation of Crossrail. As a project entity, Crossrail complies with the requirements of ROGS and other railway-related safety regulations[12].

The framework of the risk management process is based on the analysis and evaluation of hazards using one or more of the following risk acceptance principles:

- application of codes of practice;

- comparison with similar systems (reference systems); and

- explicit risk estimation.

Passengers’ Rights and Obligations (PRO) Regulation

The European Passengers’ Rights and Obligations (PRO) Regulation[13] applies to all rail journeys and services provided by railway undertakings licensed in accordance with Council Directive 95/18/EC of 19 June 1995 on the licensing of railway undertakings (Article 2.1 of the PRO regulation). The 1995 European directive has been repealed and replaced by European Directive 2012/34/EU establishing a single European railway area. In the UK, the 1995 and 2012 European directives have been implemented through the Railways Act 1993 and its subsequent amendments.

Article 21 of the PRO regulation (as implemented in the UK through the Rail Passengers’ Rights and Obligations Regulations 2010) obliges railway undertakings and station managers to comply with the Technical Standard for Interoperability (TSI) for persons with reduced mobility[14]. A domestic exemption was in place for all but the core obligations of the PRO regulation, but this expired on 3 December 2019[15].

Commission Regulation (EU) No 1300/2014 of 18 November 2014 on the technical specifications for interoperability relating to accessibility of the Union’s rail system for persons with disabilities and persons with reduced mobility[14]

This TSI is only applicable to the public areas of the stations and their zones of access controlled by the Railway Undertaking, Infrastructure Manager or Station Manager (Article 2.1.1). This technical specification of interoperability sets the following requirements:

- To latch or unlatch a manually operated door, for use by the public, the control device shall be operable by the palm of the hand exerting a force not exceeding 20N (Article 4.2.2.3.1.(2)).

- The force required to open or close a manual door shall not exceed 60N (Article 4.2.2.3.3.(3)).

- A door control device shall have visual indication, on or around it when enabled and shall be operable by the palm of the hand exerting a force not greater than 15N (Article 5.3.2.1.(1)).

Health and Safety at Work etc Act 1974

Crossrail has statutory duties defined in Health and Safety at Work etc Act 1974.

- 2(1) of the Health and Safety at Work etc Act 1974 imposes a general health, safety and welfare duty on employers towards to their employees:

2.-(1) It shall be the duty of every employer to ensure, so far as is reasonably practicable, the health, safety and welfare at work of all his employees.

- 3(1) of the Health and Safety at Work etc Act 1974 imposes a general health and safety duty on employers towards persons other than their employees:

3.(l) It shall be the duty of every employer to conduct his undertaking in such a way as to ensure, so far as is reasonably practicable, that persons not in his employment who may be affected thereby are not thereby exposed to risks to their health or safety.

- 40 of the Health and Safety at Work etc Act 1974 reverses the normal burden of proof, so that it is for the accusedmust prove that it was not practicable, or not reasonably practicable to do more than was done, or that there was no better practicable means than that used to satisfy the duty or requirement. This places a more onerous burden on the defendant than the normal legal burden of proof requirement of being “innocent until proven guilty”.

The Regulatory Reform (Fire Safety) Order 2005

The Regulatory Reform (Fire Safety) Order 2005 consolidates existing legislation (it repeals the Fire Precautions Act 1971 and various regulations and replaces them with a single new set of regulations), but also imposes new duties.

Probably one of the most important aspects of this Order is that it defines a premises as “any installation on land”. The definition is very wide ranging and includes a rail tunnel.

Equality Act 2010

The Equality Act 2010 defines a number of “protected characteristics” for the definition of discriminatory practice, including age and disability.

Both direct and indirect discrimination based on any protected characteristic is deemed to be an offence against the 2010 Act.

- 136 of the 2010 Act applies a reverse burden of proof, in that if there are facts from which the court could decide, in the absence of any other explanation, that a person has contravened the 2010 Act, the court must decide that a contravention has occurred, unless the defendant provides a valid defence.

The Equality Act 2010 requires service providers to consider

- whether the current arrangements put people with disabilities at a ‘substantial disadvantage’;

- the ‘physical features’ that contribute to any disadvantage that people with disabilities may experience; and

- the nature of any ‘reasonable adjustment’ that may be required in order to overcome any substantial disadvantage.

4.2 Common Law Duty for Health & Safety

Employers and providers of public services are legally obliged to reduce risks to tunnel workers and users to a level that is “as low as reasonably practicable” (ALARP), in accordance with its common law duty (Edwards v National Coal Board [1949] 1 All ER 743). In its judgment, the Court of Appeal stated that:

“… a computation must be made by the owner in which the quantum of risk is placed on one scale and the sacrifice involved in the measures necessary for averting the risk (whether in money, time or trouble) is placed in the other, and that, if it be shown that there is a gross disproportion between them – the risk being insignificant in relation to the sacrifice – the defendants discharge the onus on them.”

Employers and providers of public services is thus obliged to implement measures to reduce risks in its tunnels, unless the cost of doing so would be grossly disproportionate in comparison with the life safety benefit. The test of disproportionality is part of the “suitable and sufficient risk assessments” prescribed by s. 3(1) of the Management of Health and Safety at Work Regulations (1999).

4.3 Guidelines, Standards and Good Practice

Following UK and international guidelines may provide evidence to a court that a dutyholder has discharged their duties, for example with respect to its duty to reduce the risks of fire to a level as low as reasonably practicable, and by following a code of practice in accordance with CSM. Provision of such evidence is likely to be persuasive but is unlikely to be conclusive, since other evidence may also be required. Departures from standards may be used by an injured party to claim that Crossrail has failed to discharge its statutory and common law duties.

The Health and Safety Executive recommends that risk mitigation measures established by “good practice” should be considered as a means of discharging the dutyholder’s duty of care, wherever possible. Where such “good practice” cannot be followed, alternative risk mitigation measures should be put into effect, to deliver an equivalent or better level of safety. This is analogous to the requirement in European Union law in relation to railway safety risks – “where an alternative approach is not fully compliant with a code of practice, the proposer shall demonstrate that the alternative approach pursued leads to at least the same level of safety” (Article 2.3.6 of EU Regulation No 402/2013)[16].

5 Physiological Measurements and Analysis

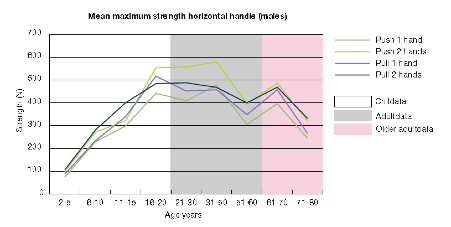

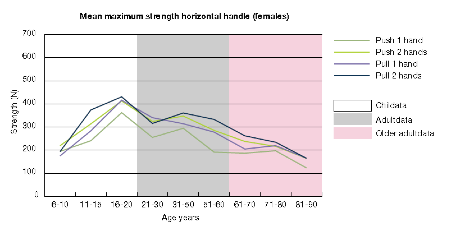

The Department of Trade and Industry[1] commissioned Nottingham University to survey the strength of around 150 male and female British citizens, of ages between 2 and 86. Subjects were grouped into 5 or 10 year age bands, with around 15 individuals in each band, although this varied slightly between each measurement. The mean maximum strengths measured on a horizontal handle are presented in Figure 2 for males and Figure 3 for females.

Figure 2. Mean Maximum Strength for Males

Figure 3. Mean Maximum Strength for Females

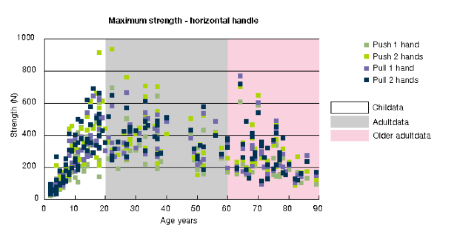

Although previous projects have relied upon the mean maximum strength values reported by the DTI, observation of the wide scatter in the measurements (Figure 4) suggests that this may not be reliable.

Figure 4. Maximum Strength with Horizontal Handle Showing Scatter

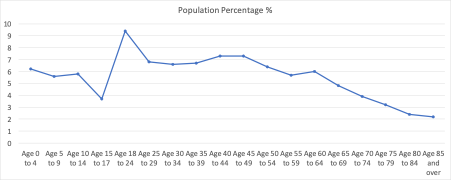

In order to provide a more reliable basis for the selection of the maximum allowable push strength on a horizontal handle, the reported mean and standard deviations for each age range were analysed from the DTI data. The population distribution was assumed to be in accordance with the 2011 UK census (Figure 5).

Figure 5. Age Distribution as per 2011 Census[17]

An assumption was made that the strength measurements follow a Gaussian distribution. On that basis, the proportion of individual females failing to push open a door against a particular force was plotted in Figure 6. Table 1 summarises the key findings.

Figure 6. Proportion of individual females (over 16 years) failing to open door

Criterion % Failure (females 16 and over) 100 N (original Crossrail criterion) 2.6% 220 N (BS 9992) 23.2% 255 N (current working limit for C610 doors) 34.5% Table 1. Percentage of Individual Females Failing to Open Door

6 Door Opening Force Recommendations

6.1 General Approach

In selecting the door opening force recommendations below, we have relied upon the application of codes of practice. The application of relevant codes of practice is a risk acceptance principle acknowledged by the ORR as satisfying the requirements of the Common Safety Method[18]. The correct application of codes of practice may demonstrate compliance with the requirements of the Health and Safety at Work etc Act 1974, the Regulatory Reform (Fire Safety) Order 2005 and the Equality Act 2010, and providing evidence that a dutyholder’s common law duty for health and safety has been properly discharged. In addition, technologies and products pertaining to such standards are generally available on the market, and the experience of applying such standards is more readily available than any ad-hoc selection.

6.2 Door Forces within Stations

It is anticipated that the majority of evacuations will be undertaken within the stations, since Crossrail operating procedures dictate that whenever possible, trains should continue to the next station in case of fire or other emergency[19]. The selection of appropriate maximum door forces to a CSM standard must therefore consider the anticipated preponderance of emergency evacuations within stations.

6.3 Doors Leading to Places of Relative Safety for Persons with Restricted Mobility (PRM)

It is assumed that PRM may need to self-evacuate into the disabled refuges. On some occasions PRM will be assisted to evacuate from the station platform, either by an accompanying person or by station staff, whose duty it will be to assist with their evacuation[20].

It is therefore proposed that the maximum allowable opening forces along PRM evacuation routes from a platform to a place of relative safety for the Crossrail underground stations are:

- 30N from 0° (the door in the closed position) to 30° open, and not more than 22.5N from 30° to 60° of the opening cycle, in accordance with BS 8300. Since this is not a realistic target for the current doors, it is very likely that doors leading to disabled refuges should be motorised. Such mechanical door openers may be installed on only one door leaf, if the width of a single door leaf is 800 mm wide or greater – sufficient to allow a wheelchair to pass through[9].

Such installations would be compliant with requirements of the Equality Act 2010 and would reduce the risk to PRM to a level that is compliant with a valid code of practice (in accordance with CSM).

6.4 Passenger Escape Doors in Evacuation Shafts (non-PRM Routes)

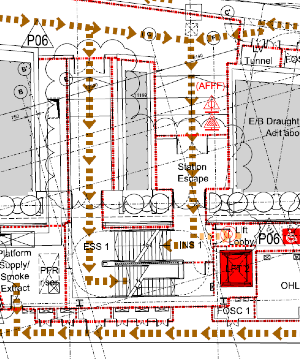

In some stations such as Farringdon, passenger escape doors are available at the ends of the platforms (blue circle in Figure 7), leading to evacuation shafts which are separate from the doors leading to the disabled refuges. The primary escape route for passengers within these stations will be up the escalators, which comprise the most capacious evacuation routes.

Figure 7. Farringdon Station – East Side of Platforms, showing Fire-fighting and Evacuation Shafts

For these locations, the maximum allowable door opening force should be 220N, in accordance with BS 9992. Such a force would be openable by around 77% of females who are 16 years old or over, and by the vast majority of adult males. For the balance of cases, the door could still be opened if assistance is provided by another passenger or member of staff.

It is proposed that other station doors for passenger evacuation that are not specifically designed for PRM egress (including emergency escape doors, platform screen doors, doors at the top of evacuation shafts and doors within interlink passageways) should also exhibit maximum opening forces of 220N or less.

Door function Location Performance target Maximum opening force Passenger self-evacuation Platform end doors 100 N (BS 9999) 220 N (BS 9992) Doors leading to fire-fighting shafts at each end of the platforms Doors to outside from the fire-fighting shafts Doors leading to evacuation shafts at each end of the platforms Doors to outside from the evacuation shafts Emergency escape doors (within platform screens) Platform screen doors Doors within the interlink passageways at interchange stations Door function Location Maximum opening force Leading to places of relative safety Doors along evacuation routes from platforms, for passengers with reduced mobility (PRMs) 30 N (BS 8300), or

at least one mechanically operated door leaf per door-set along the path from platform to a place of relative safety

Table 2. Recommended Maximum Door Forces within Stations

Conclusions

The door opening forces recommended in this paper for the Crossrail stations have been reviewed and accepted by the various stakeholders. Applications for any departures from the recommendations here are to be submitted in the form of site-specific risk assessments.

Definitions

Abbreviation Meaning CSM

DTI

Common Safety Method

Department of Trade and Industry

EED Emergency escape door HSE Health and Safety Executive NFPA National Fire Protection Association OPE

ORR

Over-platform exhaust

Office of Rail and Road

PRM Person with reduced mobility PSD Platform screen door RAIB Rail Accident Investigation Branch ROGS The Railways and Other Guided Transport Systems (Safety) Regulations 2006 RRO The Regulatory Reform (Fire Safety) Order 2005 TED Tunnel evacuation door TfL Transport for London TVS Tunnel ventilation system References

[1] “Strength data for design safety – Phase 1”, DTI, October 2000

[2] Report VBN-V047-1159-GEN-DOC-000010, “NTH SF001 & SF002 Stair Pressurisation Technical Note, Door Forces and Differential Area Pressure”, 21-09-2017

[3] SPG-VCP-RPT-BNK-007-R01, DLR Fire Door Opening Force Evaluation, 15/05/2018

[4] MMD-N001-2360000-GEN-MEM-00003 Technical Note – Assessment of Door Opening Force, 28/02/2017

[5] BS 9992:2020, “Fire safety in the design, management and use of rail infrastructure — Code of practice”

[6] S1067 – Tunnel and public area cooling and ventilation

[7] BS EN 12101-6:2005, Smoke and heat control systems. Specification for pressure differential systems. Kits.

[8] NFPA 130 – Standard for Fixed Guideway Transit and Passenger Rail Systems, 2020 edition

[9] BS 8300-2:2018, “Design of an accessible and inclusive built environment. Buildings. Code of practice”

[10] ITA-COSUF report on “Current practice on cross-passage design to support safety in rail and metro tunnels”, ISBN: 978-2-9701242-4-5, May 2019.

[11] Regelwerk SBB; I-20036; Selbstrettungsmassnahmen in Tunnel; 05/2015

[12] “Health and Safety Standard for Contractors and Industry Partners”, Crossrail, 2015 edition.

[13] Regulation (EC) No 1371/2007 of the European Parliament and of the Council of 23 October 2007 on rail passengers’ rights and obligations

[14] Commission Regulation (EU) No 1300/2014 of 18 November 2014 on the technical specifications for interoperability relating to accessibility of the Union’s rail system for persons with disabilities and persons with reduced mobility

[15] Letter from Marcus Clements, Head of Policy at the Office of Rail and Road, to a number of railway infrastructure owners including London Underground Ltd, 22 October 2019.

[16] Regulation (EU) No 402/2013 of 30 April 2013 on the common safety method for risk evaluation and assessment and repealing Regulation (EC) No 352/2009.

[17] https://www.ethnicity-facts-figures.service.gov.uk/uk-population-by-ethnicity/demographics/age-groups/latest (accessed on 17/02/2020)

[18] Common Safety Method for Risk Evaluation and Assessment Guidance on the application of Commission Regulation (EU) 402/2013, September 2018

[19] Tunnel Ventilation System – Operating Strategy, CRL Document Number: C610-ATC-H-STP-CRG03-50001

[20] Woolwich Station Fire Strategy, C530-BBR-O9-RGN-CR147-50001 Rev 8.0, 31/10/201920

-

Authors

Dr Fathi Tarada BSc LLB MBA DPhil CEng FIMechE FIFireE FICE

Dr Fathi Tarada is the founder and managing director of Mosen Ltd, an engineering consultancy. He is qualified in engineering, management and law and is a leading expert in fire safety engineering, tunnel ventilation and Computational Fluid Dynamics. Fathi is the inventor of the MoJet® ventilation system, a patented energy-efficient device that has been installed in tunnels worldwide. He represents the United Kingdom at the Technical Committee on Road Tunnel Operations for the World Road Association (PIARC), and was awarded a medal for Construction Health & Safety by the Institution of Civil Engineers.