Introduction

Crossrail included a requirement in its Works Information that all materials should be procured in accordance with the ETI (Ethical Trading Initiative) basecode, founded on the conventions of the International Labour Organisation (ILO) and is an internationally recognised code of labour practice.

It was soon recognised by Crossrail and its tier 1 contractors that a collaborative approach was required to achieve any significant progress in assuring the supply chains. This led to the formation of the Crossrail Ethical Supply Chains in Construction(ESCIC) working group, Chaired by Crossrail with membership from procurement specialists within the Tier 1 contractors. The group met regularly to identify key issues, risk areas and developed a process and outputs to help procure the selection of materials and products in a more informed manner. Commitment to the group was agreed through a Terms of Reference for the participants. The resources developed by the ESCIC include:

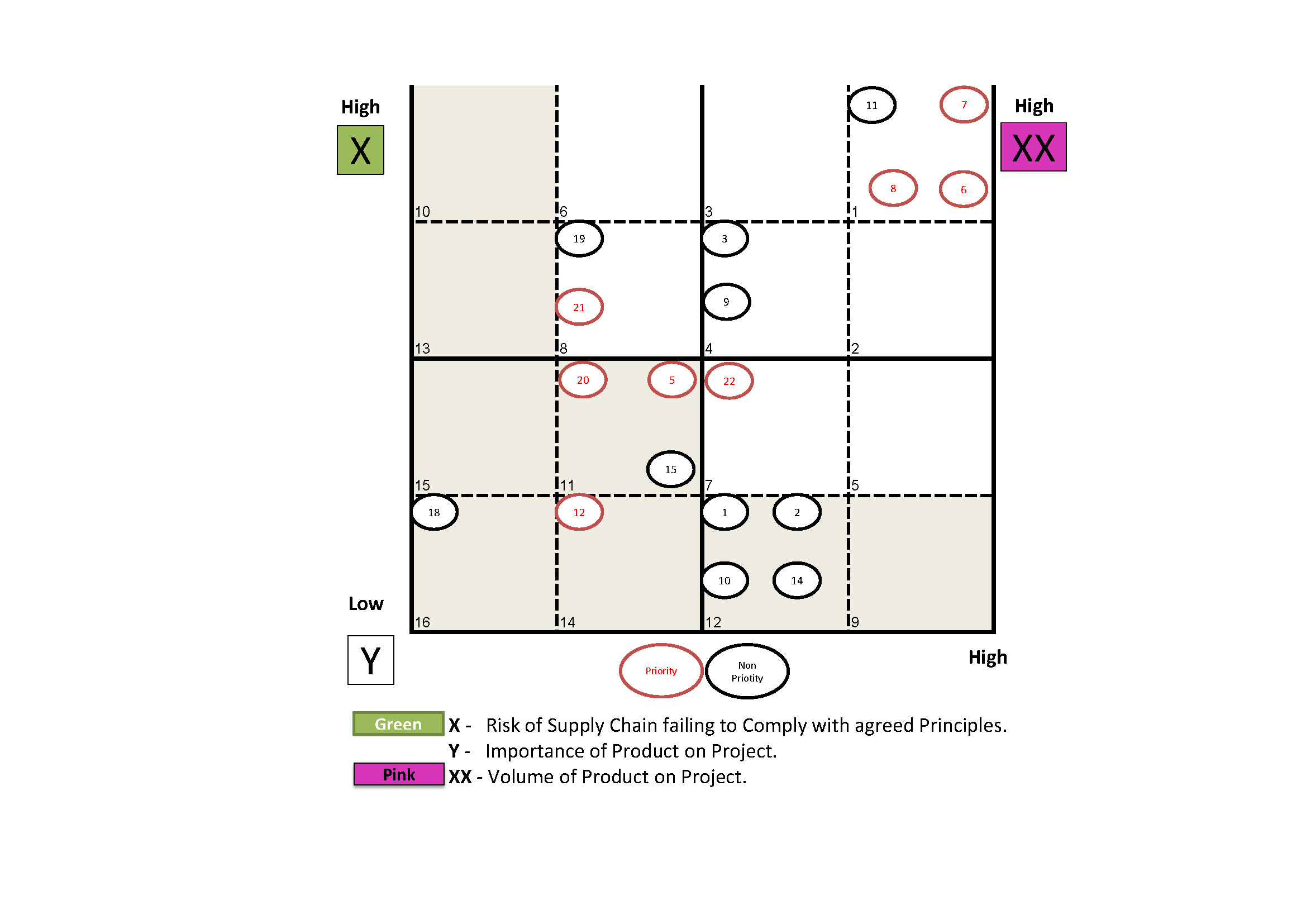

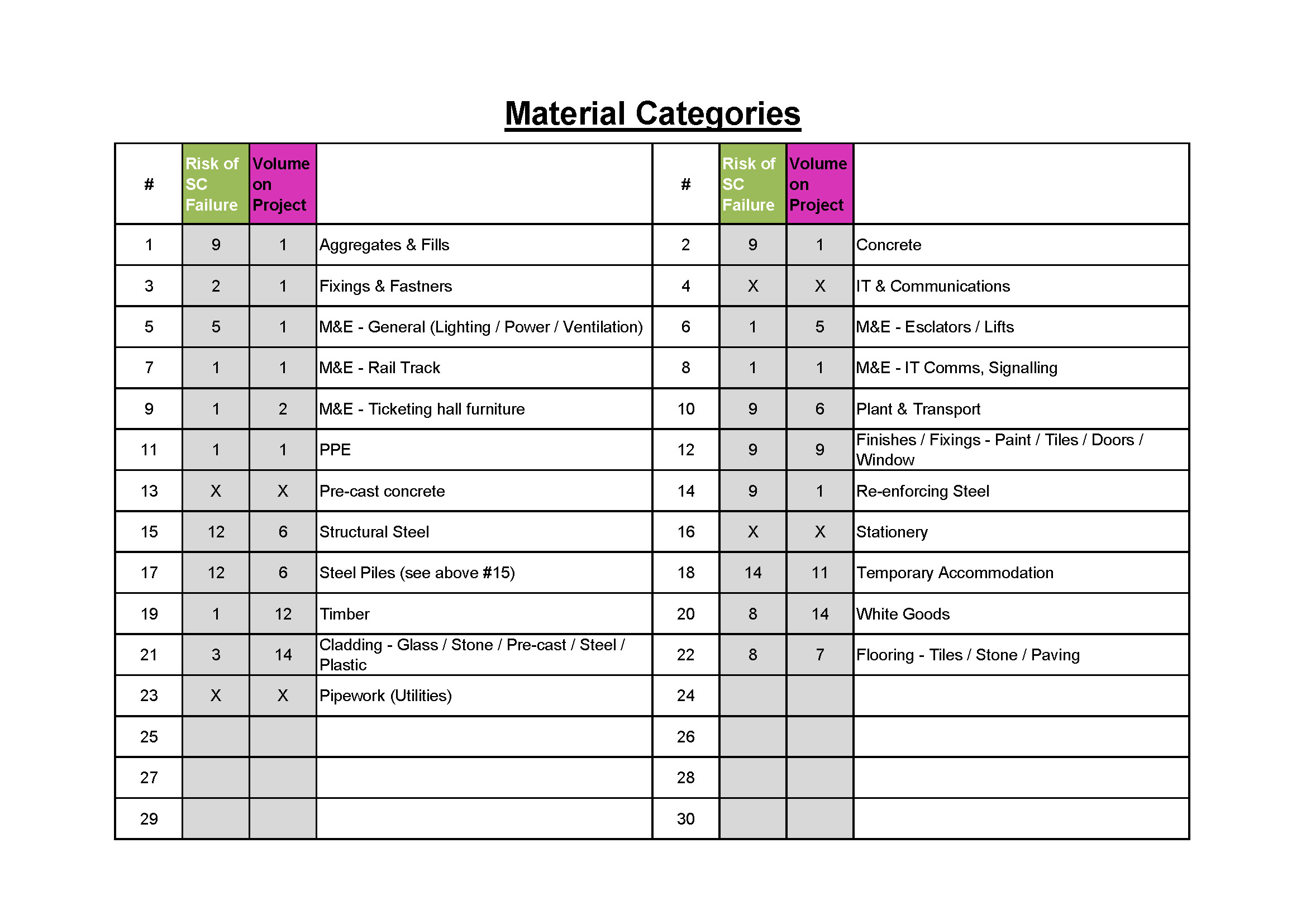

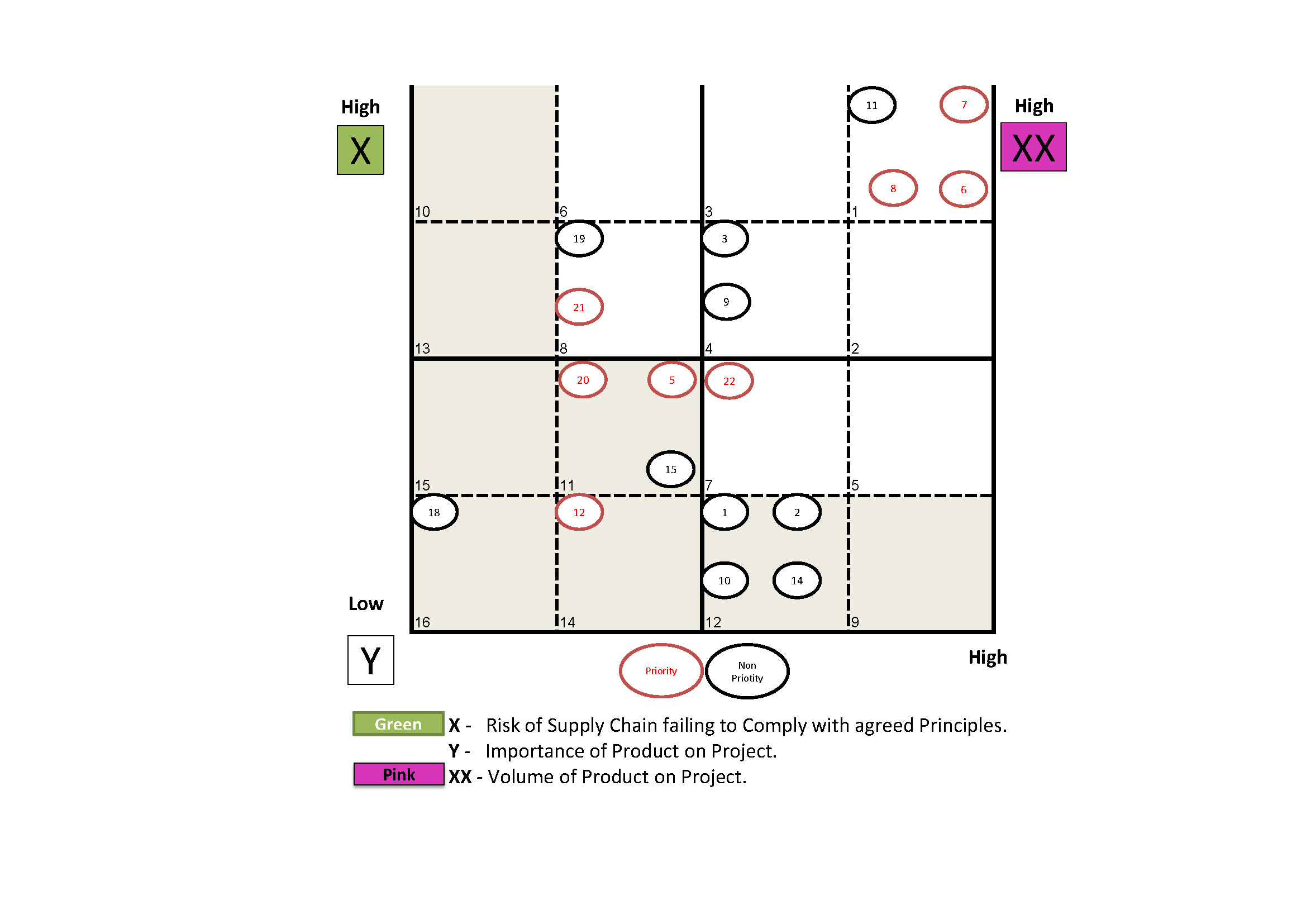

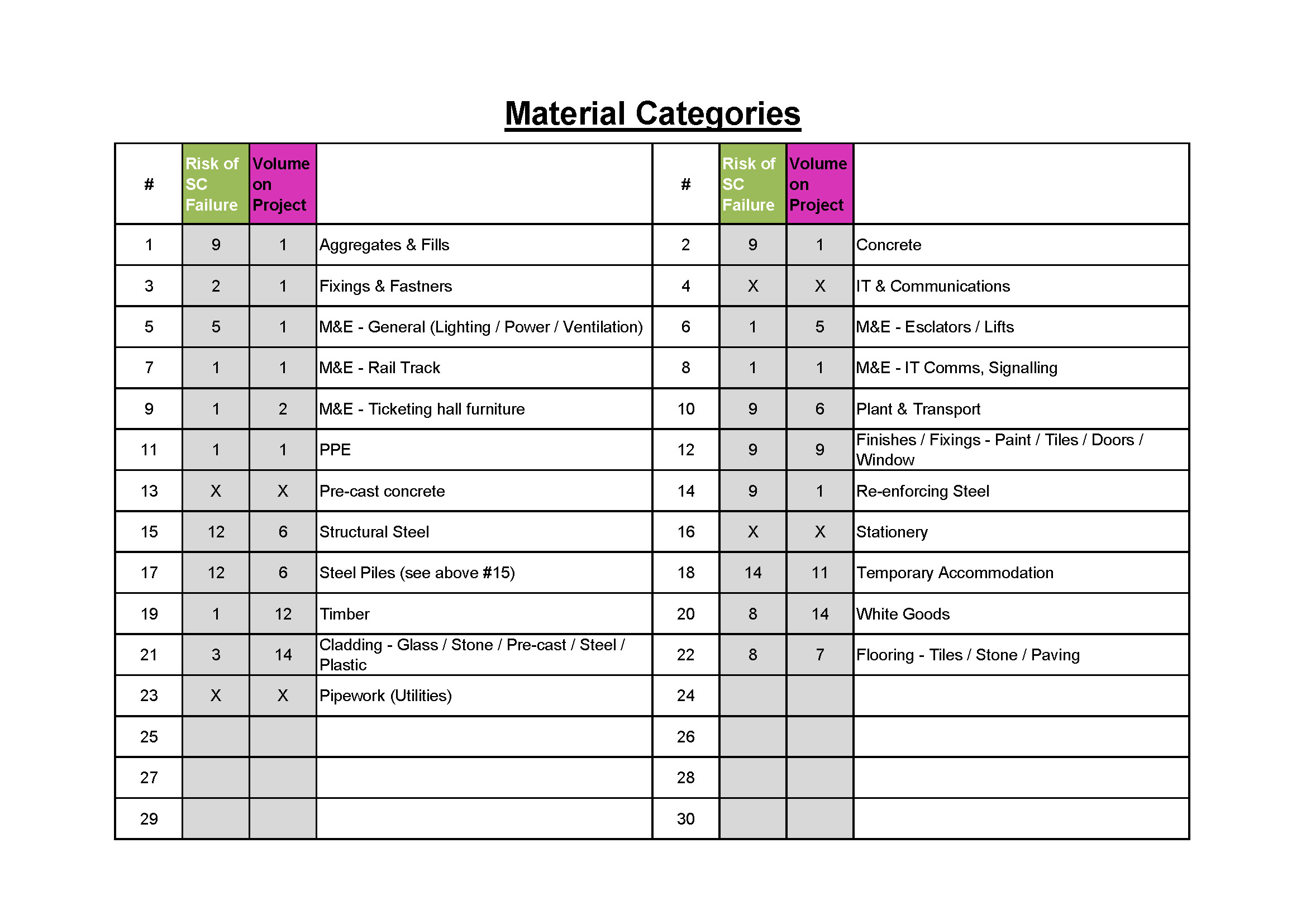

- Risk assessment framework using the Kraljic matrix:

Kraljic (1983) suggested that purchasing in many companies is based on routine transactional activities, that afford little strategic consideration to potential economic and political disruptions to materials supplies. His 2×2 matrix set out to provide companies with a way to distinguish between different types of purchasing strategies which maximise buying power while minimising supply risks.

“No company can allow purchasing to lag behind other departments in acknowledging and adjusting to worldwide environmental and economic changes. Such an attitude is not only obsolete but also costly”. (Kraljic)

The principles of the Kraljic matrix were adapted by Crossrail’s ethical sourcing working group to attribute risk and opportunity to key construction materials and components. This decision was made after consultation with procurement colleagues within our tier 1 contractor organisations who identified that the method was equally suited to quantifying ethical sourcing risk.

- 6 Commodity sheets detailing key issues associated with a particular material:

- Best practice social audit template for evaluating risk for materials not covered by any form of responsible procurement certification.

What is the benefit to future projects?

Construction supply chains are very complex, particularly when purchasing components that are composed of multiple parts procured through global supply chains. In this globalised market, many of the raw materials and components originate in jurisdictions where human rights violations are either endemic or international codes of practice on labour are not adhered to. Identifying these risks is important from both a reputational management perspective and increasingly enshrined in corporate strategies of clients, contractors and other tiers of the supply chain. The Crossrail ESCIC working group identified a clear vacuum in this area and the collaborative outputs have helped to fill some of these gaps, thus providing a valuable resource for future projects. It should be emphasised that this is a very complex area and there is still much to be done. Crossrail is now ready to pass the baton to the next major project so that the resources developed to date can be used to address ethical issues in supply chains, but importantly so future projects can build on this legacy