Final Design Overview – A Crossrail Design Assurance Process

Document

type: Technical Paper

Author:

Nick Morgans MEng CEng MIMechE

Publication

Date: 24/11/2021

-

Abstract

Assurance is defined as all the systematic actions necessary to provide confidence that the target deliverables have been met.

Assuring the Crossrail design proved extremely challenging due to the complexity and scale of the system and, with the designs being delivered via a significant number of different contracts, demonstration of a complete and fully integrated design was key.

The task of integrating the designs for the numerous aspects of the project – stations, shafts, portals and the various systems which makes up the end-to-end railway, and the task to demonstrate the collective designs are safe, operable, maintainable and perform (the Crossrail ‘4 Pillars of Assurance’) and meet the agreed requirements cannot be overstated.

In order to demonstrate this design integration and to test the designs against the 4 Pillars of Assurance, Crossrail, in collaboration with the Infrastructure Managers, developed the Final Design Overview (FDO) process.

The implementation of the process consisted of the following key steps:

- A series of FDO reviews covering all Crossrail Central Operating Section assets over a period of 8 months;

- Review and approval of an agreed list of key assurance deliverables for each asset and for the Programme (a total of 1000+ items of evidence);

- Collation and close out of an agreed list of outstanding issues (2000+) categorised to identify those critical for completion and sign off of each FDO;

- Signed FDO Certification covering all assets;

- FDO Reports covering all assets and a Programme FDO that are agreed with the IM and that baseline the FDO Design.

This Technical Paper will set out the details of the Final Design Overview Process and will describe the solutions employed to resolve some of the key challenges faced during its implementation.

-

Read the full document

1 Introduction and Industry Context

The complexity and scale of the Crossrail system raised significant challenges in relation to integration and assurance of the overall design. Designs were delivered via many different contracts, each with their own timeline and therefore it was necessary for Crossrail to establish a robust process to review and assure itself, and the future Infrastructure Managers (IMs), that the final designs were integrated and complied with all requirements.

Designs were produced for all aspects of the Crossrail Central Operating Section (COS) – stations, shafts, portals and the various systems which make up the end to end railway, and assurance was required that the collective designs not only meet all the agreed requirements but that they are safe, operable, maintainable and perform (the Crossrail ‘4 Pillars of Assurance’). The challenge of demonstrating the integration of the designs and compliance to the 4 Pillars of Assurance across the full extent of the railway cannot be overstated.

In order to demonstrate this design integration and to test the designs against the 4 Pillars of Assurance, Crossrail, in collaboration with the IMs, developed the Final Design Overview (FDO) process[1]. The FDO process assessed the final design of the Crossrail Project (Elizabeth Line) and how this design supported the planned Crossrail service and network.

The outputs of the FDO process, captured through the Programme FDO report and the supporting Element1, FDO reports, achieved a key objective of confirming the acceptance of the design by the IMs. They also provide significant evidence to support the ‘Design Complete’ argument of the Crossrail Engineering Safety and Assurance Case (CESAC).

2 Background

In accordance with the Crossrail Technical Assurance Plan (TAP)[2] designs produced by contractors followed the Engineering Design Assurance Gates Procedure[3] which provided assurance at a contract level through a series of design checkpoints, known as Gates 1, 2 and 3. Gate 3s captured the contractor’s final design supported by a Final Design Submission (FDS), the equivalent of a design compliance submission for the contractor’s scope of work. However, in order to be able to hand over the Railway in ‘Elements’ e.g. a complete station, in line with the Crossrail Project Handover – Strategy and Plan[4]) it was necessary for Crossrail to demonstrate assurance and integration at the Element level and to demonstrate that the Elements integrated to deliver the whole at a Programme level.

Consequently, Crossrail developed and implemented a two-stage assurance review of each Element of Crossrail. This supported Crossrail’s commitment to progressively assure design and to mitigate Crossrail’s design risks and it demonstrated integrated assurance to the IMs.

The two stages comprised:

Interim Design Overview (IDO)

In order to de-risk the production and acceptance of the FDOs, Crossrail committed to the production of an Interim Design Overview (IDO) which assembled the available FDO evidence at an earlier stage in design. The production of an IDO provided a ‘snapshot in time’ as to the progress being made in producing a coherent set of integrated designs that will result in a safe, functional railway.

The Interim Design Overview (IDO) Process[5] was carried out for each Element and captured the Infrastructure design up to RIBA Stage F, MEP (Mechanical, Electrical, Public health) & Architectural designs up to RIBA Stage E, Railway Systems Design Statement at 30% complete and associated Crossrail integration evidence, and provided the initial building block towards the Final Design Overview.

Final Design Overview (FDO)

The final design overview scope related to each Element and a Final Design Overview (FDO) Process[1] was developed, describing the requirements of a formal FDO review process, supporting evidence list, certificate and FDO report.

This process describes how the complete Civils, MEP, Architecture and Systemwide designs are assessed along with their coordination and integration into the final design. The process was carried out on each Handover Element which may comprise a single component e.g. a Station, or multiple components, e.g. Railway Systems, as defined within the FDO Process[1]. Crossrail produced a Final Design Overview (FDO) report and FDO Certificate for acceptance by the relevant IM for each Element of the Crossrail railway2.

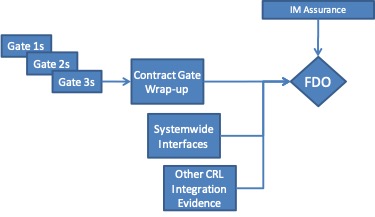

The figure below shows how the assured Gated (refer to [3]) designs for an Element’s main (Tier 1) contractor, along with assurance of the integration with systemwide interfacing designs and the relevant Crossrail evidence to demonstrate integration across the contracts that constitute the Element, fed into an Element level FDO. As shown below, where contracts held multiple Gate 3s covering different aspects of design, a ‘wrap up’ Gate was held to draw together all the contractor’s Gate 3s to demonstrate integration across the full scope of the contractor’s designs. This was a pre-requisite to the commencement of the Element FDO.

Figure 1: Inputs to FDO

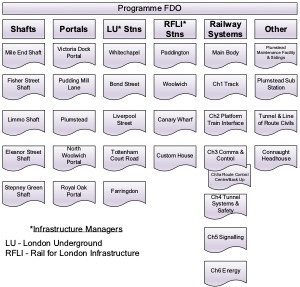

The Element level FDOs combined to give a complete design for the Crossrail COS and these were supplemented with a Programme level FDO that brings together the Elements and the interfaces to the other areas of the network. The following presents a picture of the make-up of all the formal reviews and the associated FDO Reports produced in order to demonstrate an integrated design across the programme:

Figure 2. FDO Elements

3 The FDO Process

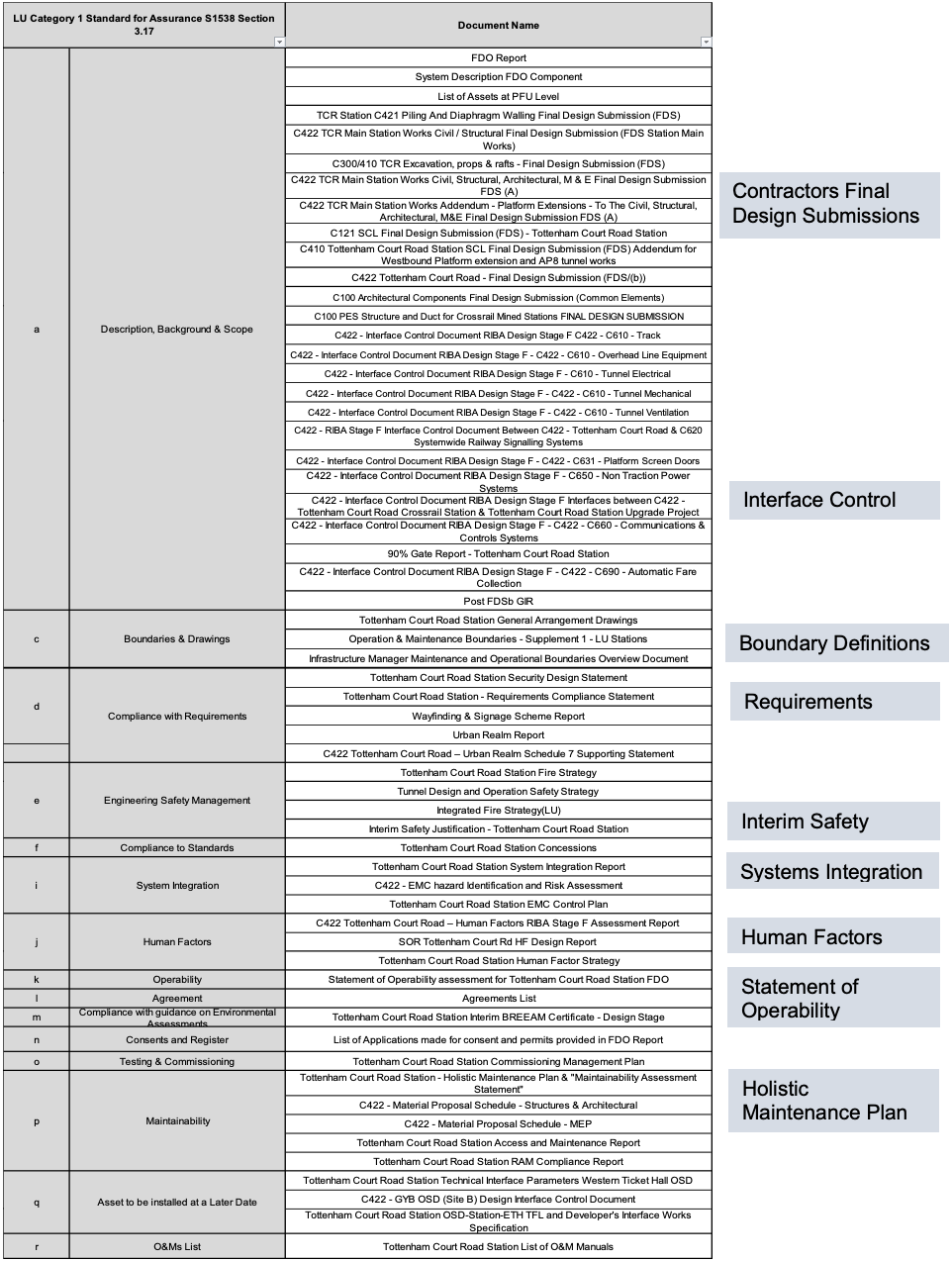

At the Element level the FDO sought to provide assurance against Crossrail’s “4 pillars” of assurance, namely Safety, Maintainability, Operability and Performance and to provide the equivalent of a Compliance Submission as described within the London Underground (LU) Assurance Standard S1-538[6].

In addition to demonstrating integration at the Element level, at the programme level the process demonstrated how the sum of the Elements provides a compliant design that delivers a railway to match the Sponsors Requirements. The intention being to support the demonstration of integration of the Elements forming the route, including the various systems forming a part of the COS infrastructure, and their integration with the systems of connecting railway infrastructure.

In order to provide a recognisable and consistent structure to each of the FDOs, the requirements of S1-538 Clause 3.17 Content of a Compliance Submission were used to define the assurance evidence requirements to support the FDO. These clauses also provided the structure of the FDO report itself, defining the template to be used for all Element reports. For consistency, the presentation format for the formal FDO Reviews held for every Element followed a similar structure. This led to a recognisable pattern for those involved in the process whereby the status of design assurance for the scope of each Element was presented (FDO Review), evidenced (FDO Evidence List) and recorded (FDO Report) in a consistent manner that was aligned to the requirements of the LU Assurance Standard.

In parallel, the process supported Crossrail’s commitment to provide assurance against the 4 pillars in the following way:

3.1 Safety

Crossrail demonstrated that the Element is safe and in compliance with LU’s Assurance Standard S1-538 clause 3.17.1 e). The Crossrail Engineering Safety Management process and activities formed an integral part of the FDO process.

Assurance was evidenced through the production of a RAB(C)3 (Railway Assurance Board (Crossrail)) accepted Interim Safety Justification (ISJ). RAB(C) acceptance followed the IM’s acceptance of risk control actions at Hazard Review Panels (HRP) – for the integrated Element.

3.2 Maintainability

Crossrail demonstrated that the Element is maintainable in compliance with S1-538 clause 3.17.1 p) through the production of a Crossrail Holistic Maintenance Plan (accepted by the IM) for each Element that was jointly produced with the IMs and refers to their Maintenance Readiness plan. Closure of all issues identified through the MIRP4 (Maintenance Integration Review Panel) process is included within the Holistic Maintenance Plan.

3.3 Operability

Crossrail demonstrated that the Element is operable in compliance with S1-538 clause 3.17.1 k) and in accordance with the Operational Concept and/or evolved Use Cases for the Element and closure of all issues identified through the SIRP5 (Systems Integration Review Panel) process. The demonstration of operability through the output of the SIRP process is captured in a Statement of Operability Assessment.

3.4 Performance

Crossrail, through performance modelling and the production of RAM Compliance reports, demonstrated that the Elements meet the Sponsors required performance.

By defining the above requirements, it was then possible to develop the process itself, and in collaboration with the IMs the formal suite of FDO procedure documents was created.

These documents included:

- A Detailed FDO Acceptance Process Flow

- Roles & Responsibilities

- FDO Review Meeting Terms of Reference

- FDO Report Template

- FDO Evidence List Template and Tracker

- FDO Certificate Template

A series of briefings to both Technical and Delivery Directorates including all Project teams then took place in order to communicate the requirements of the process and to initiate its launch.

4 FDO Programme

Due to the complex and multi-disciplined nature of the Crossrail design, carrying out a comprehensive review of the design status of every Element involved significant resources spread across the Crossrail Directorates. However, the importance of the exercise was recognised at a senior level and supported accordingly. It was also recognised that in order to allocate the time and resources to the review process, it was necessary to have a robust plan in place that would allow the participants to organise their time accordingly.

In an ideal situation the FDO reviews would all have occurred after the detailed RIBA F1 design for each Element was fully concluded. However, due to challenges encountered completing aspects of design it became increasingly difficult to finalise the order and timing of every FDO Review, with constant requests to rearrange dates and times and to swap reviews in order for projects to be fully ready to embark on the FDO. Programme constraints compounded this with less and less time becoming available in which to carry out the reviews and consequently, after numerous exercises to re-baseline the FDO Programme, the decision was made to freeze it. All projects were instructed accordingly and committed to meeting their allocated Review dates.

It was agreed that one FDO review would be held per week, spreading the review process over approximately 8 months, with sessions arranged on the same day every week and at similar times (depending on duration) lasting from 3 hours e.g. a portal, to a full day e.g. a station review.

This decision to freeze and implement the programme proved an extremely important decision. As evidenced by the number of comments raised through the reviews, there were a lot of issues still to be resolved and waiting on resolution of the majority of these before holding the FDOs would have been preferable, however it would have resulted in an unmanageable FDO programme. Another key benefit of fixing the programme was that it flushed out the underlying open issues and actions and allowed them to be collated into the FDO Comment Log and the FDO Evidence List Trackers, allowing them to be openly managed through to closure.

5 The FDO Reviews

In preparation of each formal FDO Review, a Readiness Review was held at which the Project presented the status of their design and associated FDO evidence to a subset of the FDO Review attendees. Whilst establishing the readiness of the Project to proceed into the FDO process, it also provided an opportunity for attendees to advise and guide the projects on where to focus efforts prior to the FDO Review.

A formal review chaired by the Crossrail Chief Engineer (or Deputy) was held for every FDO Element in line with the agreed FDO Review Meeting Terms of Reference[7]. Each review was attended by the Project Team, CEG (Chief Engineer’s Group) Discipline Engineers, Assurance team Heads/Leads, IMs and Operators and was presented by the Project Manager, assisted by the Manager of Engineering. The Assurance team, through the Head of Technical Assurance and the FDO Manager, facilitated the reviews and captured all actions throughout the course of the meeting.

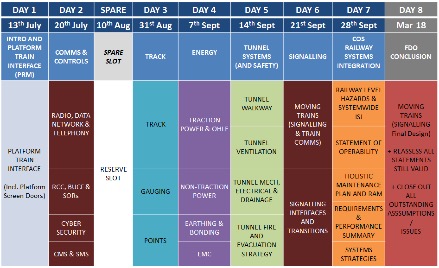

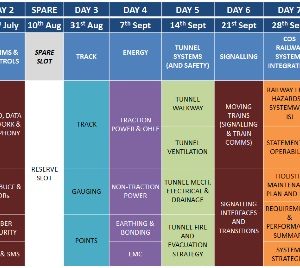

Due to number of systems included within the Railway Systems Element it was necessary to break the reviews (and FDO Reports) into manageable subsystems and as such the Railway Systems review was split into a 7 day process (plus one day allocated at the end to conclude the process). The subsystems were covered as follows:

Figure 3. Railway Systems Review Breakdown

Throughout the implementation of the review process huge amounts of assurance information were presented and captured through the various outputs. The key outputs for each Element consisted of:

- FDO Evidence List (these were consolidated into one Stations, Shafts, Portals (SSP) Tracker consisting of a series of excel worksheets and one Railway Systems Tracker)

- FDO Review Presentation

- FDO Comment Log (the list of issues identified through the reviews culminating in one consolidated SSP Comment Log and one Railway Systems Comment Log)

- FDO Certificate

- FDO Report

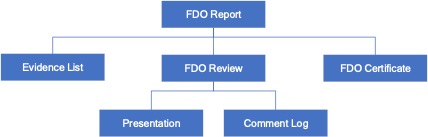

The outputs fed up into the FDO report which pulled together the different aspects of the exercise and collated them into one overall document as shown below:

Figure 4: Key Components Supporting the FDO Report

6 Outputs of the Process

6.1 FDO Evidence List

The Template for FDO Evidence List and Tracker [8] was defined through interpretation of the requirements of LU Standard S1-538 Clause 3.17 (a-t). This provided a list of assurance documentation that it was agreed would provide suitable evidence to meet the requirements of each clause and would support the 4 Pillars. It consists of a combination of contractor documentation and evidence required to be produced by Crossrail in order to demonstrate integration, and where particular evidence required IM review and acceptance this too was identified.

This clear list of FDO related deliverables (see Appendix A) was provided to each Project team to work to and was utilised by the Assurance Team to track the status of each FDO. The Assurance team developed a combined FDO Evidence List Tracker[9] containing the status of every single FDO deliverable for SSP, and a similar tracker for Railway Systems[10]. These 2 master trackers, updated daily during the height of FDO activities, provided a complete overview of the status of FDO supporting evidence.

6.2 FDO Presentation

Each Project team produced an FDO Presentation to support their FDO Review. The presentations were all structured similarly, in line with the contents of the FDO Report and the FDO Evidence list i.e. following the requirements of S1-538 Clause 3.17.

The presentations provide an important record of the formal review and status at that time and are a key reference within the FDO report.

6.3 System Description

A System Description was produced to align with each FDO, providing a clear description of the scope of the FDO and clearly identifying any exclusions (this was clarification, where necessary, of items that were not part of the scope of the FDO) and omissions (any particular aspects of design that were within the scope of the Element but were not complete at the time of the FDO).

6.4 FDO Comment Log

During the course of FDO Review sessions any specific issues/actions/comments raised were captured by a designated recorder and agreed during the review. This list was reviewed at the end of each session and a RAG status agreed for every item:

- Red – Close out critical for completion of FDO e.g. an incomplete aspect of design;

- Amber – Requires closure but not critical for FDO e.g. a post design issue;

- Green – Minor issue or observation.

Following the review, all issues raised through the IMs own assurance process, carried out in parallel to the FDOs, were also added to the Comment Log.

This log became an incredibly important aspect of the review, as it gathered the key outstanding design issues across the whole programme, as agreed by all attendees, along with the IMs list of design related issues. It also captured the agreed status in relation to criticality for completion of the FDO process.

The log captured over 2000 issues (which included 873 Reds and 924 Ambers) across SSP, Civils e.g. Tunnels, and Railway Systems (see Fig 3 above) and was worked on daily to track progress and status of every issue. The Technical Assurance team owned the master Comment Logs (one for SSP and one for Railway Systems) and coordinated all updates provided by the Project teams. Due to the volume of information flowing at the peak of the process (information on the status of 100s of issues per week) it was necessary to develop ways of automatically updating the master files from information submitted via spreadsheets from individual projects. This was achieved through development of macros to automatically pull data from Project teams’ spreadsheets into the master file on a weekly basis. Projects would submit their updated spreadsheets by a designated time each week and the following day a macro would be run to extract all updates and automatically update the master tracker with the information. The Technical Assurance team would then analyse the updates and identify candidates for closure. These would be reviewed and either agreed closed with the appropriate party e.g. the comment originator, or returned to the project with a request for further information.

All comments were given a baseline RAG status and a ‘current’ RAG status along with an Open/Closed/Proposed Closed status. Statistics were produced automatically to capture and monitor status and to measure progress of all issues and these were communicated at a minimum of weekly across the Programme.

All Red issues were required to be closed in order to obtain a complete set of signatures on an FDO Certificate. An approved FDO Certificate was a prerequisite for completion of the FDO Report.

6.5 FDO Certificate

The FDO Certificate captured a signed declaration from the Technical Directorate Heads of Discipline, the Crossrail Integration Team and the Chief Engineer and completion was necessary to support finalisation of the FDO Report. Each project team was responsible for obtaining sign off of their FDO Certificate.

6.6 FDO Report

In order to capture the FDO process for each Element and to provide the equivalent of a Design Compliance Report under the requirements of S1-538 Clause 3.17, a separate FDO report was produced to cover each FDO Review. A Programme FDO report was also produced to capture the output of all the individual FDO reviews.

The structure of the report was aligned to the sub clauses of S1-538 3.17 and, therefore, aligned with the structure of the FDO Evidence List and the FDO Presentation. A Final Design Overview (FDO) Report Template [11] was produced and agreed with the IMs in parallel to the production and agreement of the FDO Procedure and this set out a generic contents list and guidance on the requirements to complete each section.

The FDO Reports were written by the Crossrail Technical Assurance Team and provide details of all the key evidence underpinning the FDO. Consequently, the associated Technical Directorate Discipline Engineers and Engineering Managers played an important role in ensuring the satisfactory completion of the evidence required to be in place to allow the FDO Report to be completed.

The FDO Report was the last item to complete on conclusion of all the evidence items, close out of all red issues (and as many ambers as possible), and completion of the FDO Certificate. On completion the FDO report was signed by the Head of Technical Assurance and the Chief Engineer prior to issue to the relevant IM for Acceptance.

7 FDO Close Out

The completion of the FDO review process was a significant milestone but was by no means the end. As a consequence of the reviews 873 ‘red’ and 924 ‘amber’ issues were raised and required closure, 31 FDO reports had to be written and approved, all associated FDO Certificates required approval and all outstanding documents from the 1000 plus evidence documents had to be closed out.

The Technical Assurance team, through the FDO Manager and a number of supporting resources owned the master Comment Logs and the Evidence Lists and was responsible for producing the FDO Reports. As owner of the Comment Logs, the Technical Assurance team controlled the close out of every issue, ensuring sufficient and appropriate justification was in place prior to closure. Where issues were raised by the IM, this would include obtaining confirmation from the IM that their issue could be closed. As owner of the Evidence Lists the Technical Assurance team monitored progress of every item and tracked the current status through to completion.

8 Reporting

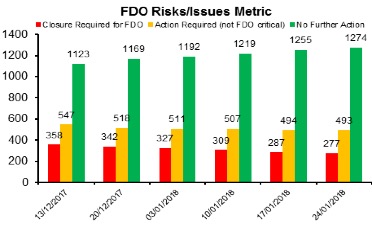

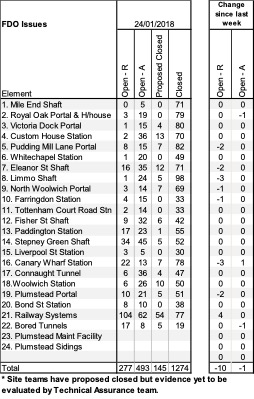

As the focal point for the FDO Process the Technical Assurance Team were responsible for the production and communication of status of the FDO Process and the progress towards close out of the FDOs. This took the form of a weekly dashboard style report capturing, for example, the overall number of red/amber/green issues (see Fig 5), the numbers of open red and amber issues per Element (see Fig 6), the closure trend and the status of each FDO report. The status was provided for each individual FDO and where site teams had submitted evidence to support closure of an issue this was identified as ‘Proposed Closed’ in order to acknowledge both the site team effort and the lag between submission of evidence and the review and acceptance of this.

Figure 5. FDO Risk/Issue Status Metric

Figure 6. FDO Issue Status Breakdown

Eventually, as more and more FDOs were closed out and in line with the general reporting format across the Programme, the FDO Report took the form of a weekly ‘Vis Board’6, reporting on overall FDO status and specific FDO evidence items and red issues that were preventing completion.

9 Responsibilities

The FDO Manager, as a member of the Crossrail Technical Assurance team managed the overall process from production of the FDO Process and supporting documents, to production of the FDO programme and organisation and management of the FDO reviews. Following the reviews, the FDO Manager was responsible for overseeing and tracking the close out, by the Projects, of the FDO comments/issues raised, the completion of the evidence items and sign off of the FDO Certificate. On satisfactory completion of these items the FDO Manager was responsible for producing the FDO report to capture all aspects of the FDO process for each Element.

The FDO Manager was supported by an FDO Evidence Coordinator who owned and managed the FDO Comment Logs. This required constant liaison with project teams to obtain updates on closure of items and associated update of the Logs. Regular reporting was required to Projects and to senior stakeholders to communicate the status of the FDO comments and to show trends and forecasts for closure. The Evidence Coordinator was also responsible for drafting justifications for closure of each item in the logs and obtaining confirmation from relevant parties e.g. the originator of a comment, the Head of Technical Assurance or in the case of an IM comment, the IMs Assurance Manager, that a comment could be closed.

With such a wide range of supporting evidence required to be produced there was necessarily a long list of producers of documentation ranging from Tier 1 contractors e.g. Concessions, Final Design Statements, Interface Control Documents, to Crossrail Integration team leads e.g. Statement of Operability, Requirements Compliance Statement, and to Crossrail Chief Engineer’s Group e.g. Security Design Statements and the Tunnel Design and Operation Safety Strategy.

The Project teams including Engineering Management leads, Project Managers, Field Engineers and Supervisor’s Representatives were crucial with regards to the management and provision of evidence for each of their projects from the various producers along with completion of the sign off of the FDO Certificate by the many Heads of Discipline.

The Heads of Discipline and the Chief Engineer drove the process throughout the review period and provided the support necessary to enable to reviews to be successfully completed.

10 Lessons Learned and Recommendations for Future Projects

There have been many lessons learned during the course of a process that has taken several years to complete, however some of the key ones, along with recommendations for future projects are as follows.

With a programme as complicated as Crossrail, with multiple contracts and complex, interfacing designs, there was never going to be an ideal time to run a process that aimed to review the design of the complete scope. Therefore, the lesson was learnt that at some point it will be necessary to make the call and fix the programme. Choose a time to do the reviews (a judgement call is needed to judge when the design is mature enough but not necessarily every detail in place) and then stick to it. The temptation is to keep putting it off until everything is in place but better to put a line in the sand and identify all the requirements, the issues, the outstanding work etc and to then close these out through controlled processes.

The volume of issues that would be raised was not fully appreciated until a significant number of reviews had been held. By this point it was becoming clear that it would become a significant task, requiring dedicated resource, to manage the maintenance and close out of the issues logs. A robust mechanism was required and even though this evolved as the process was implemented it proved to be very effective. However, this meant that it was an evolution of the spreadsheets initially created with a relatively small amount of data in mind, and managing the large volume of issues and evidence in this way is very time consuming and susceptible to error. The recommendation would be to not underestimate the number of issues that a task of this size will reveal and to have a system in place that is appropriate to manage a significant number of issues ‘live’, that constantly require access and updates by several different parties, often at the same time. It needs to be robust, have the necessary controls in place with regards to close out of issues and, with frequent updates required and reporting statistics to be extracted, the more automated it can be, the better.

It may seem obvious but conclude the process as quickly and efficiently as possible. Projects move quickly and focus moves from one project phase to the next and as it does the time that people have to put into what might be seen as ‘old news’ becomes limited. During this exercise, after the majority of FDOs were closed out and agreed with the IMs, resources were reallocated, and it became increasingly difficult to get engagement from all parties to conclude the remainder. Understandably, attention turned to testing, commissioning and handover and as such the recommendation would be not to be tempted to take resource from this when it looks like it’s a done deal, keep it resourced until it is.

11 Conclusion

The exercise of developing and implementing the FDO Process as a means of demonstrating an integrated design for a programme the size and complexity of Crossrail was a huge undertaking. However, it allowed Crossrail to demonstrate compliance against the IMs standards and against its own 4 Pillars of assurance. It proved invaluable in providing a mechanism for Crossrail and its key stakeholders to understand the status of the design and the issues to be resolved, along with the tools to allow the complete suite of design assurance across the full scope of works to be understood and made visible. It provides a record of the design that was assured by Crossrail and accepted by the future IMs of the system.

Footnotes

1. The Crossrail Project infrastructure has been packaged into Elements with groups of assets and/or systems forming each Element e.g. a station is an Element. It is at the Element level that Handover activities from Crossrail to the IM take place.

2. Note – For the purpose of the paper the individual FDOs have all been referred to as Elements. However, some FDOs were split down further into ‘Components’ in order to facilitate the review and reporting process e.g. Railway Systems is an Element however it was split into several components e.g. the Signalling system, that were represented by individual FDO Reviews, Reports and Certificates.

3. Crossrail, as design authority, established a Rail Assurance Board Crossrail (RAB(C)) which, during the Project phase up to handover, acted as the Crossrail Limited (CRL) System Review Panel (SRP) for acceptance of all Central Operating Section (COS) assets.

4. The MIRP process was designed to provide confidence, through a series of workshops, that the design of the COS and its interfaces take cognisance of, and are properly integrated with, the Crossrail Maintenance Principles and are maintainable within the Crossrail Project Functional Requirements (CPFR) permitted access.

5. The System Integration Review Panel (SIRP) existed to provide assurance of the operability of the completed Central Operating Section assets and the interfaces with the existing operators’ equipment and validated the alignment between the baseline designs and operations concepts.

6. Visualisation Boards were weekly reports used to present key statistics for all aspects of the programme in a consistent, clear format, from detailed site level data to board level reports.

References

[1] Final Design Overview (FDO) Process – CRL1-XRL-O7-GPS-CR001-50009

The purpose of this document is to describe the FDO and the inputs required in order to achieve design compliance and demonstrate integrated design assurance.[2] Technical Assurance Plan (TAP) – CRL1-XRL-O7-STP-CR001-50003

The TAP clarifies the processes Crossrail uses to progressively deliver the technical assurance evidence to the IMs that supports acceptance by demonstrating that a safe, operable, maintainable, railway – that achieves the required levels of performance and capacity – has been delivered.[3] Engineering Design Assurance Gates Procedure – CRL1-XRL-O7-GPD-CR001-50015

The purpose of the Engineering Design Assurance Gates procedure is to provide progressive assurance during the design stage that the objectives of the project will be achieved and that the project can progress successfully to the next stage. The key checkpoints through the design phase are known as Gates 1, 2 and 3.[4] Crossrail Project Handover – Strategy and Plan – CRL1-XRL-K1-STP-CR001-50001

The Handover Strategy and Plan outlines the programme approach, and describes the delivery detail, for the successful transfer of the Crossrail Project Elements e.g. a station, to the relevant IMs.[5] Interim Design Overview Process – CRL1-XRL-O7-GPS-CR001-50003

In order to de-risk the production and acceptance of the FDOs, Crossrail committed to the production of an Interim Design Overview (IDO) which assembled the available FDO evidence at an earlier stage in design.[6] LU Assurance Standard S1-538

The purpose of this Standard is to define the requirements for the management and delivery of assurance by both providers and receivers of assurance.[7] Final Design Overview Review Meeting Term of Reference – CRL1-XRL-O-STP-CR001-50004

Terms of Reference for the forum where an Element e.g. a station, is presented to demonstrate a fully integrated, complete design in accordance with the Crossrail TAP.[8] Template For FDO Evidence List and Tracker – CRL1-XRL-O7-ZTM-CR001-50020

Microsoft Excel spreadsheet template used to record the details and status of each item of evidence provided in support of an FDO Report.[9] FDO Evidence List and Tracker – CRL1-XRL-O7-LRC-CR001-50004

Consolidated Excel spreadsheet providing the details and status of FDO supporting evidence for all stations, shafts and portals.[10] FDO Railway Systems Evidence List and Tracker – CRL1-XRL-O7-LRC-CR001-50005

Consolidated Excel spreadsheet providing the details and status of FDO supporting evidence for all Railway Systems.[11] Final Design Overview (FDO) Report Template – CRL1-XRL-O7-ZTM-CR001-50019

Microsoft Word report template used to produce each separate FDO report in a consistent manner.Appendix A – Evidence List

-

Authors