Programme Efficiency and Cost Reduction During the Delivery Phase

Document

type: Micro-report

Author:

Mike Laws ACMA CGMA MBA, Richard Wood BSc MRICS

Publication

Date: 14/03/2017

-

Abstract

Crossrail is committed to safely deliver a world class railway, on time, and at the lowest possible cost. It is required of all involved in the delivery and management of the programme to drive efficiency and maximise value for money.

In 2015, the Crossrail leadership team agreed cost reduction targets with key projects across the programme, with the aim of further instilling the cost reduction culture required to deliver the programme’s objectives.

This paper describes this approach, as well as the process, tools, systems and communication channels which underpinned it, and will be of use for any publicly funded project or programme, or any project looking to drive out cost during the delivery phase.

-

Read the full document

Introduction and Industry Context

Crossrail is a complex, high profile programme with a large number of internal and external stakeholders. Crossrail also presents unrivalled technical and engineering complexity; all of which within the context of working within and beneath one of the worlds largest and busiest cities.

Public funding brings with it a significant requirement for transparency and effective governance to ensure value for money. Crossrail uses industry and Government best practice to drive efficiency into everything it does, which is supported by all levels of management within Crossrail.

What Crossrail Did

Crossrail is committed to safely deliver a world class railway, on time, and at the lowest possible cost. It is beholden on all involved in the delivery and management of the programme to drive efficiency and maximise value for money.

In 2015, the Crossrail leadership team agreed cost reduction targets with key projects across the programme, with the aim of further instilling the cost reduction culture required to deliver the programme’s objectives. These targets were included in the performance management system for Project Managers.Effective target setting enabled project management teams to become more outcome focused, within the overall objectives of the programme. Targets were set in an informed manner, utilising robust programme controls data and regular and in-depth dialogue with those closest to the projects. Recognising that the involvement of the supply-chain was crucial to achieving these targets, they were openly communicated with the main contractors in the spirit of collaboration and to maximise participation by those who could effect change.

To support the project teams in delivering these targets and to further embed this culture, the Programme Controls team implemented a number of support structures as outlined below:

Performance Analysis and Reporting

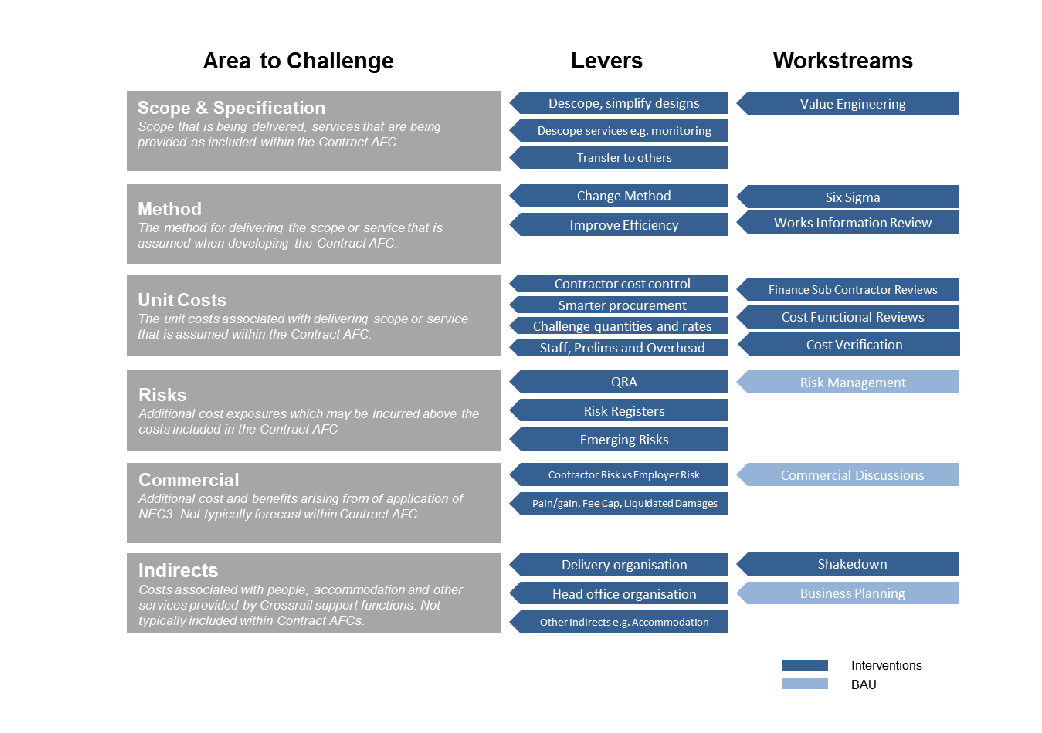

To support the project teams in achieving their cost reduction targets, a framework was developed which identified areas of cost to challenge, as well as the existing processes and interventions that could be utilised to affect change:

Figure 1 – Cost Reduction Framework

Much of what is contained in the framework were existing processes to maximise value, but the framework served as effective tool with which to structure cost saving activities and to communicate with the wider programme and external stakeholders.

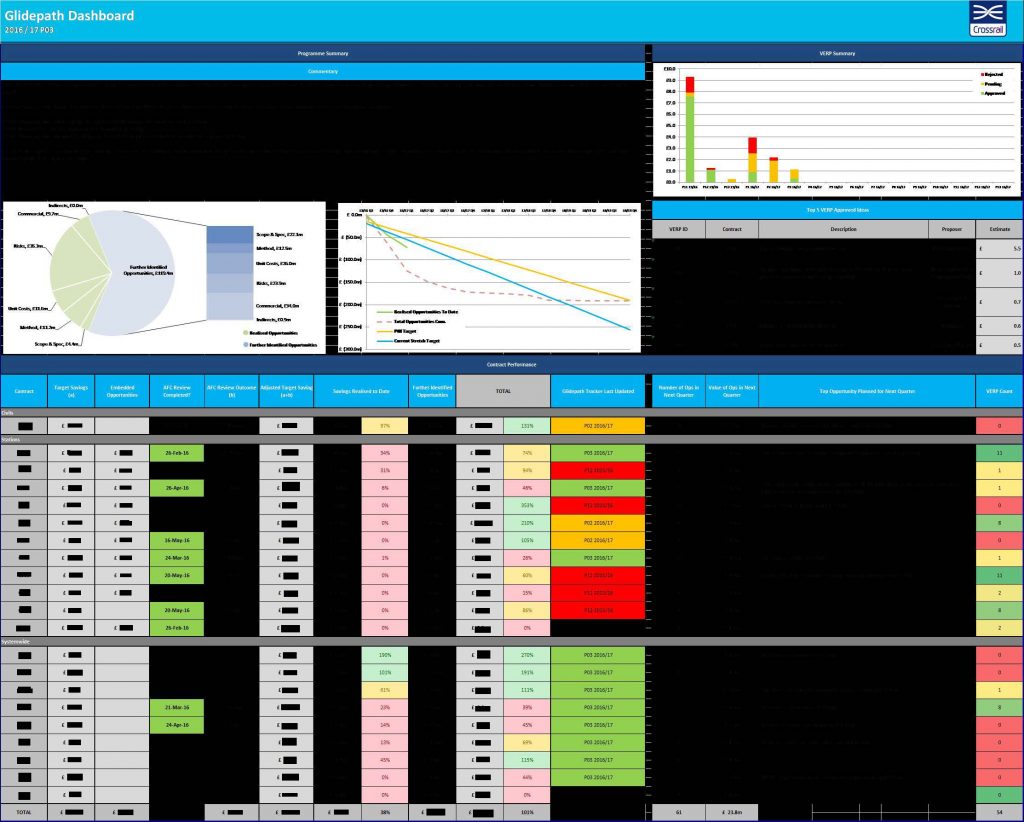

Templates and guidance material were also developed such that the project teams had a ready made toolkit to assist in the identification, recording and realisation of cost reduction ideas. The utilisation of standard templates also allowed data to be captured in a consistent manner across the programme against the six areas of the framework above. This enabled the efficient collection and analysis of data, and the robust reporting of progress to the Crossrail Board. A periodic progress dashboard, was created which detailed:

- The cost reduction targets and any subsequent amendment to these targets

- The value of realised opportunities achieved to date

- The value of further identified opportunities, and the timescales to realise these opportunities

- Quantum of Value Engineering proposals submitted by each project, and the approved proposals which could be applied elsewhere on the programme

- Compliance with processes

Figure 2 – Glidepath Dashboard example

This dashboard is provided to the Crossrail Commercial Director and Programme Controls Director as well as the Head of Cost, the Head of Change Management, the Head of Reporting and the Head of Programme Efficiency ahead of the periodic Programme Delivery Board meetings. Discussion on cost reduction initiatives has been made a mandatory agenda item within these Programme Delivery Board meetings, and the dashboard serves to provide a collated programme view for the leadership team in order that the project teams can be challenged appropriately.

Project Cost and Glidepath Reviews

Subsequent to the setting of the cost reduction targets, the senior finance and commercial team, led by the Finance and Commercial Directors increased their levels of engagement with the project teams by embarking on a series of deep dive reviews into cost and commercial performance, which supplemented the normal periodic review processes. Actions to meet the targets were reviewed for suitability, acceptability and feasibility of proposals. Progress is assessed, both in terms of “how well are you doing?” and “how hard are you trying?” Having the senior leadership engage with the project teams precipitated a review of base assumptions by the project teams, and provided assurance on the project’s anticipated final cost forecast.

Value Engineering Review Panel

To support the project teams in developing cheaper, better ways to deliver the required output, a Value Engineering Review Panel (VERP) was established. The VERP sits twice a period with the objective of providing fast decisions regarding the suitability (will it save time and money?), acceptability and feasibility of value engineering proposals before they enter the formal governance process. The VERP is chaired by the Central Section Delivery Director and attended by members of the technical, maintenance and operations departments. The VERP provides a dedicated pathway for ideas to be submitted by project teams into the central engineering function, and provides approvals for proposals to be developed further. Due to the nature of value engineering proposals, the VERP was primarily focused on ideas falling within the ‘Scope and Specification’ category of the framework as shown above.

Application of Six Sigma

Crossrail implemented Six Sigma techniques on a reactive and proactive basis to drive greater efficiency into processes and methodologies as shown in the framework above. For example, the Six Sigma team were able to collaboratively work with Crossrail’s Systemwide contractor to drive greater productivity from the concreting train through optimising planning and preparation work and reducing mechanical breakdowns. These improvements resulted in an acceleration of 56 days to planned completion, which translated to a £3.4m cost avoidance benefit to Crossrail. This work was accomplished using the ‘Rapid Turnkey Deployment’ model, where advanced planning and targeted interventions enable an agile approach and shorten the improvement cycle. This process improvement initiative won Bechtel’s 2015 Six Sigma Excellence Award.

Knowledge sharing

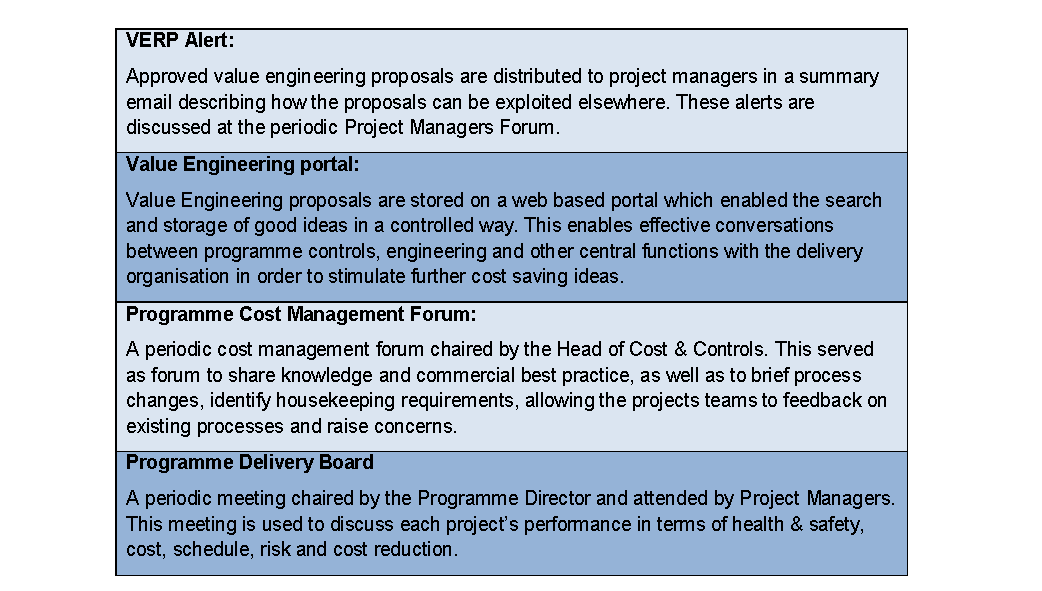

Each of these lines of development yielded benefits in terms of a reduction in programme costs and an improvement in the level of understanding across the organisation with regards to specific project complexities and their interfaces. Crossrail seeks to leverage the learning of the individual projects through sharing knowledge across the programme. This is done in a variety of formal and informal settings, using both written and oral communication as set out below in Table 1.

Table 1 – Knowledge Sharing Development

Commercial Assurance

The Crossrail Commercial Assurance function supports cost and commercial performance improvement across the most commercially valuable contracts as part of the over-arching Performance Assurance Process. This is achieved through the sharing of best-practice across the programme and through identifying the specific input processes which deliver improved commercial performance. Cost reduction initiatives and processes that are in place at the project level were a key component of the commercial assurance process. The commercial assurance and performance assurance processes are explained in more detail in the associated learning legacy papers linked.

Lessons Learned

- The cost reduction process established during the delivery phase of Crossrail, lead to a cost reduction culture being instilled across the programme, throughout the delivery teams and supply-chain

- This was underpinned by the setting of cost reduction targets, which were embedded into the performance management process, with progress measured through senior leadership meetings and on-site assurance

- The establishment of a formal process supplemented with tools, templates and guidance enabled data to be captured in a consistent way across the programme, enabling efficient and effective upward reporting to senior managers and sponsors

- The creation of a cost reduction framework enabled the clear communication of the processes available to support each category of saving

- Establishing effective knowledge sharing across the programme proved challenging initially, and required a central shared access sharepoint site to be created. This was supplemented with communications through existing forums and meetings in order to maximise the potential for knowledge sharing

- The creation of a Value Engineering Review Panel enabled value engineering proposals to be agreed in principle by delivery, engineering, maintenance and operation leadership, prior to time and effort being expended on the further development of proposals (e.g. prior to fees being expensed on design alterations)

Recommendations for Future Projects

- The deployment of a structured cost reduction process, underpinned by cost reduction targets can be effective in driving out cost during delivery

- In order to instil an effective culture, the deployment of such processes should be considered proactively, instead of in response to cost pressures

- The supply-chain should be considered key participants

- Consider the use of a Value Engineering Review Panel

-

Authors

Mike Laws ACMA CGMA MBA - CH2M, Crossrail Ltd

Mike is Head of Reporting at Crossrail. A programme manager with 10 years experience in delivering large, complex change programmes, principally for public sector clients. Mike has been supporting the Crossrail Programme controls function since March 2015.

Richard Wood BSc MRICS - Crossrail Ltd, Turner & Townsend

Associate Director – Turner & Townsend

Head of Cost and Control, Crossrail

Richard has over 10 working on the UK’s major infrastructure projects and programmes, including leading an integrated cost and controls managed service on the £2.5bn T2 redevelopment scheme at Heathrow, and played a key role in establishing cost and controls processes on their £3bn Q6 programme. Richard has worked on Crossrail since 2014, and has held several positions over this time, including Head of Commercial Assurance and Head of Performance Assurance. Richard took on the role of Head of Cost and Controls in March 2017.