The Management Processes adopted to deliver the Assurances given for Noise from Fixed Installations

Document

type: Technical Paper

Author:

Steven Sheridan CEng

Publication

Date: 24/08/2018

-

Abstract

This paper explains the measures that have been put in place to control the effects of noise from the operation of fixed installations designed and installed as part of Crossrail, with particular focus on the management processes adopted the deliver the associated Assurances.

The term fixed installations encompasses a wide range of noise sources, including forced ventilation & draught relief shafts, electrical trackside equipment, power supply facilities, mechanical ventilation & air conditioning equipment, rail facilities at depots & sidings (including stationary trains) and public address & audible warning systems.

The Crossrail ‘Assessment Criterion for Fixed Installations’ is in accordance with British Standard BS4142:1997, which is founded upon the difference between the noise from the fixed installations (Rating Level) and the background noise level, taking account of tonal or impulsive characteristics of mechanical and electrical services plant. The airborne noise at the worst-affected residential building (Rating Level), under normal operation of the fixed installations, shall not be more than +5dB and reasonable endeavours shall be used to reduce noise levels below this criterion, in recognition of the local authorities preference for -5dB.

The relevant Assurances include a protocol for the application of the Crossrail Design Criterion to the design of fixed installations, to be adopted by the nominated undertaker. This includes recognition that the criterion applies to the totality of all fixed installations at a single Crossrail development. This protocol also outlines the management processes to be implemented by the nominated undertaker comprising; i) incorporation of the design criterion into the contract documents, ii) recognition of the requirement for further endeavours, iii) translation of the design criterion into specific requirements for the procurement, iv) determine and jointly establish the background noise levels with the relevant local authorities, v) procure, install and commission the fixed installations to meet the specific requirements, vi) provide details regarding the adequacy of the design and procurement processes and vii) complete the standard suite of acceptance tests and provide information to the relevant local authority.

-

Read the full document

Introduction

This paper concerns the experience gained from the management of the design, procurement, testing & commissioning of the fixed installations of the central section of Crossrail (the Elizabeth line) in the process of complying with the assurances given to control operational noise from such plant during the passage of the Crossrail Hybrid Bill through Parliament.

The fixed installations covered by these assurances predominantly comprise mechanical and electrical equipment associated with the new railway, including the tunnel ventilation system, featuring very large fans located in shafts at ten locations across the central section. Additionally, the stations, shafts & portals, depots & sidings and control rooms’ mechanical ventilation and air conditioning equipment are also included, together with traction power and high voltage power systems. This case study focuses upon the delivery of compliance against the assurances for the following types of fixed installations:

- forced ventilation shafts located along the tunnelled sections;

- draught relief shafts located along the tunnelled sections;

- electrical trackside equipment located along the surface railway;

- power supply facilities e.g. transformers located along the surface railway;

- mechanical ventilation and air conditioning equipment associated with Crossrail buildings including those located at depots, sidings, control rooms and stations;

- static sources of noise located at depots and sidings (for example train washes, wheel lathes and stationary trains) but excluding noise from the movement of trains.

The ultimate objective of these Assurances was to ensure that people living in the immediately vicinity of these railway facilities were protected from any significant noise impact.

Noise from Fixed Installations – Management Processes

The Undertakings & Assurances

Any organisations that are appointed to construct and maintain Crossrail are contractually obliged to comply with all relevant Undertakings and Assurances. The Crossrail ‘Register of Undertakings & Assurances’ [1] includes specific commitments concerning ‘Noise from Fixed Installations’, namely assurances 461-465 & 517-518 (refer to Appendix 1 for the relevant extract). The requirements for the management processes to be adopted to deliver the fixed installations noise assurances are outlined in assurances 463 & 464, as the ‘Protocol for the Application of the Crossrail Design Criterion to the Design of Fixed Installations’.

Information Paper D25

The Crossrail Act was given Royal Assent in July 2008. A series of Information Papers were initially presented to the House of Commons Select Committee considering the Crossrail Bill in January 2006, some of which were revised as the Bill continued its passage through Parliament. The fixed noise assurances were all taken directly from Information Paper D25 – Noise from Fixed Installations [3] (abbreviated to IP D25). Assurances 463 and 464 were drawn directly from Section 3 (paragraphs 3.1 and 3.2 respectively) and are presented in full below for ease of reference, because there are particularly relevant to this case study:

“3. Protocol for the Application of the Crossrail Design Criterion to the Design of Fixed Installations

3.1 With the exception of public address systems and audible warning systems which are addressed solely in Section 4 of this IP, the nominated undertaker will be required to apply the Crossrail design criterion to the totality of all fixed installations at a single Crossrail development and the specific noise source defined by BS 4142:1997 shall mean all the fixed installation noise sources (including mechanical plant and machinery) installed and operated in any location within the Crossrail development. Thus, for example, at a central London station it will apply to the design of the forced ventilation shafts, draught relief shafts and station mechanical ventilation and air conditioning equipment.

3.2 When designing all fixed installations other than public address systems and audible warning systems, the nominated undertaker will be required to:

- Incorporate the design criterion into contract documents such that it will apply to the design of all the fixed installations that are to be installed and operated in any location within the Crossrail development.

- When designing fixed installations, take the further endeavours which are referred to in paragraph 2.6 or 2.9 (as the case may be) to reduce the noise below the design criterion in paragraph 2.5.

- Translate the design criterion into specific requirements in specifications for the procurement and operation of Crossrail plant, equipment and machinery for fixed installations taking into account the further endeavours referred to in bullet point 2 above.

- Determine the relevant LA90,T levels, to be jointly established with the relevant local authorities.

- Procure, install and commission plant, equipment and machinery, including noise attenuation equipment that meets the specific requirements referred to in bullet point three above.

- Provide details of the measures undertaken to ensure that, under all reasonably foreseeable circumstances, the design process and procurement process for fixed installations is adequate to achieve compliance with the design criterion taking into account the endeavours referred to in bullet point 2 above (including proposals for maintenance and monitoring) to the relevant local authority whose comments will be taken into account.

- Before the fixed installation may be operated, satisfactorily complete the standard suite of acceptance tests required for such plant and provide information on those tests to the relevant local authority.”

The above requirement for Crossrail to provide details of the measures undertaken to ensure that the design and procurement processes were adequate to achieve compliance, were presented the relevant local authorities both collectively and individually. For example, a presentation given collectively to the Crossrail Environmental Health Sub-Group (EHSG) in July 2012 is provided in Appendix 2.

Environmental Noise Requirements

In terms of methodology and targets, the key design requirements of the relevant assurances can be summarised as follows:

- Adopt British Standard BS4142:1997[4] to predict the total noise levels at dwellings;

- Take account of tonal or impulsive characteristics (i.e. +5dB acoustic features correction),

- Include an additional allowance for calculation uncertainty;

- Assess for normal operation, under all reasonably foreseeable circumstances at the worst-affected residential building;

- design the fixed installations so that, under all reasonably foreseeable circumstances the assessment at the worst affected residential building, obtained by subtracting the existing background noise level (LA90,T) from the rating level LAr,Tr of the fixed installations in normal operation, is not more than +5 dB;

- In recognition of the local authorities’ preference for rating levels which are no greater than LA90,T-5, use reasonable endeavours to reduce noise levels below the design criterion of LA90,T+5, where it is practicable to do so.

The main attribute to note in the above requirements is the recognition of the local authorities preference which represents a 10dB difference from the design criterion (i.e. +5dB to -5dB) and the use of reasonable endeavours to achieve lower than the design criterion which has the potential to result in significant noise control costs.

Evaluation of Background Noise Levels

Crossrail took a robust approach to baseline noise monitoring, undertaking an extensive programme of noise surveys across the Central Section and beyond. In the majority of cases, this monitoring was undertaken over a period of at least one week, to allow diurnal, weekday and weekend noise patterns to be captured. The assurances’ required Crossrail to ‘determine the relevant LA90,T levels, to be jointly established with the relevant local authorities’. In practical terms, this amounted to the production of Background Noise reports (based upon the BS4142:1997[4] methodology) for every Crossrail development area, which were submitted to the relevant local authority for agreement.

The process of jointly establishing the background noise levels was complicated by the fact that the assurances simply pointed to the use of BS4142, whereas in practice there were a variety of opinions regarding the interpretation of the standard. In particular, there were different and competing opinions as to what the terms ‘representative’ and ‘typical’ should be construed to mean in strictly mathematical terms. This was resolved by the local authorities instructing an independent expert to advise on this specific point, taking account of the approaches previously adopted on other major projects in the London area, in comparison with that proposed by Crossrail followed by a specific meeting of the Crossrail Environmental Health Sub-group to discuss the issues. The meeting resulted in the production of the Crossrail ‘Method for Establishing Background Noise Levels for Fixed Installation Assessments’[7] by the Crossrail EHO Sub-group – Fixed Noise Source Working Group (refer to Appendix 3 for a complete copy). In summary, this method avoided selecting the very lowest background noise level and is based upon averaging separately over the weekdays and weekend for each hour of the day (i.e. a grid of 48 values).

Derivation of Rating Level

In accordance with BS4142:1997the ‘Rating Level’ (RL dB) is the ‘Specific Noise Level’ (SNL dB) plus any adjustment for the characteristic features of the noise. Although the scope of BS4142:1997includes the assessment of new developments such as Crossrail, no guidance is provided in this standard for determining whether a range acoustic features are expected to be present or not. In the case of tones, the standard identifies ‘a distinguishable, discrete continuous note’ as an acoustic feature but provides no objective methodology for predicting the applicability of the 5dB correction at receptors. Furthermore, the consideration of tones requires narrow band acoustic analysis, whereas the standard is based upon A-weighted broadband noise levels, from which nothing can be concluded regarding the potential for tonality. Nor does the standard take account of the complete context in which the sound occurs. In summary, many of the professional judgements that are possible when investigating a noise complaint on site (e.g. audibility, acoustic features, etc.) cannot readily be translated to a purely predictive approach based around the BS4142:1997 method. In the end a +5dB correction was applied at every Crossrail development, because there were almost no situations without fans.

In cases where the predicted Crossrail receptor noise levels (i.e. SNLs outside dwellings) were expect to be significantly below the lowest background noise levels (i.e. -5dB or less) it is likely that, once operational, the Crossrail noise will be inaudible at dwellings. In such cases, it would be difficult to justify the addition of a +5dB adjustment at the testing & commissioning stage, even though this correction was required to be applied to the fixed installations’ designs.

Evolution of BS4142:1997

British Standard BS4142:1997 – Method for Rating Industrial Noise Affecting Mixed Residential and Industrial Areas was subject to a major revision with the release of BS4142:2014[5] – Methods for Rating and Assessing Industrial and Commercial Sound, which roughly coincided with the mid-point of the project’s timeline, after completion of the RIBA D/E designs.

Upon its release Crossrail reviewed the new standard to see whether any of the changes introduced could be reasonably incorporated to the design without incurring excessive cost or dis-benefit to the programme. However because a method had already been agreed for establishing background noise levels with the local authorities, and the design criteria are defined in the D25 assurance, there was little scope change resulting from the new standard. One area that was not pursued was the changes made to totalling acoustic feature corrections. Crossrail took a precautionary view that the new standard is likely to result in a decrease from the +5dB set out in IP D25 based on the 1997 version, so continued to assess under the 1997 publication of this standard.

A detailed comparison of the 1997 –v- 2014 versions of this standard is beyond the scope of this case study. However, in a positive respect it’s noted that the latest version now includes a section on ‘uncertainty’ that was absent from the 1997 version, noting that IP D25 [3] required additional allowances to be made for calculation uncertainty. Furthermore, the 2014 version provides much greater commentary and guidance on the evaluation of the background sound level, that seeks to avoid the selection of simply the lowest measured level, which was also a concern identified during the development of Crossrail’s methodology [7] for establishing background noise levels. More generally, the 2014 edition recognises the importance of the context in which the sound occurs and the need for professional judgement in taking due account of a range of relevant factors, which taken together may result in more complex assessments. However, the net benefit for future major infrastructure projects is that assessments under BS4142:2014 [5] should be more robust and less prone to an overestimation of noise impacts, which in some cases could lead to unnecessarily high levels of noise control performance and expenditure.

Crossrail’s Organisational Structure

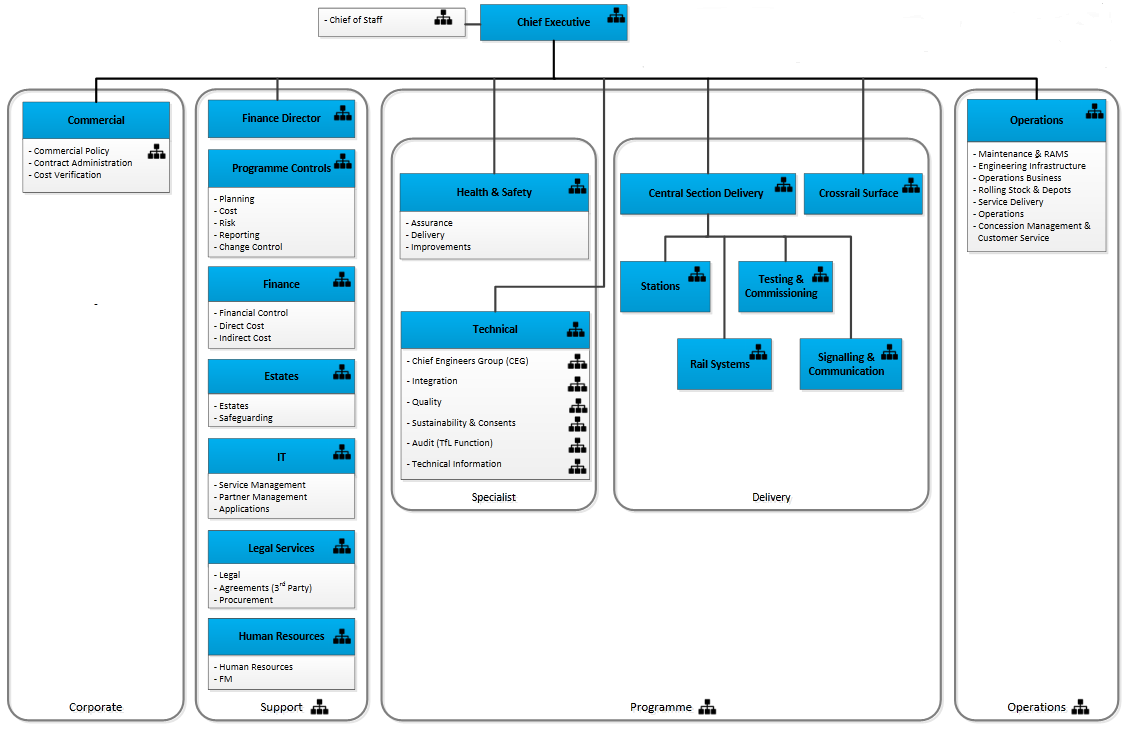

In terms of management processes it is relevant to consider the context of the organisational structure (refer to organogram below – Fig. 1) of Crossrail and where the responsibility for compliance with the assurances rests. At an administrative level, commitment compliance is tracked using a dedicated software tool (CDT) from within the Crossrail Limited’s Technical Directorate – Sustainability & Consents. This department also includes noise & vibration (N&V) specialists engaged in providing technical support to both the on-going construction and operational phases (i.e. design, procurement and testing & commissioning) of the project. It should be noted that the Technical Directorate has a wider responsibility as regards the overarching acoustic matters and this is met through the engagement of acoustic engineers in the Mechanical, Electrical & Public Health (MEP) team, within the Chief Engineers Group (CEG).

Figure 1: Crossrail Organisation Chart

The above organisation (end state 2018) represents a matrix structure and this is of particular relevance to the management processes adopted to deliver the fixed noise assurances. The Technical Directorate has accountability for the client requirements which include undertakings & assurances. Responsibility for complying with the requirements was cascaded to the contractors through the Works Information and the Delivery Directorate is responsible for managing the contractors. The Technical Directorate also provides specialist technical expertise to the Delivery Directorate and each of the projects through matrix working.

Preparation of Invitations to Tender

Professionally qualified noise & vibration specialists (i.e. Corporate Members of the Institute of Acoustics) prepared specifications for the compliance with the fixed noise assurance that set-out the technical aspects (scope, targets, methodology, etc.), deliverables and timescales, for particular contracts.

In addition, the fixed noise assurances were also cascaded directly to the relevant contractors through the Works Information. An example one of the fixed noise specifications (Noise from Fixed Installations for Deep-Level Stations [8]) is provided in Appendix 4.

The Specifications had to address the situation of the cumulative effect of multiple contractors’ designs at a given Crossrail development, as the assurances’ targets apply in totality. For example, at a Crossrail station the forced ventilation fans at either end of the station were designed and constructed by a systemwide contractor responsible for the ventilation of the entire tunnel section, whereas the station specific mechanical and electrical plant was designed and installed by the main station contractor.

Preliminary noise assessments undertaken during the design stages prior to tender identified that conventional MEP fixed plant should generally be able to achieve 10dB below background. Conversely, the necessary noise control measures associated with attenuating the tunnel ventilation system’s (TVS) fans was anticipated to be considerably more challenging. As a consequence the Specifications set a target of 10dB below background for the former and 5dB below background for the latter, with the overall objective of achieving 5dB below, cumulatively. In practice, this meant that in some cases the TVS noise contribution was required to be marginally below 5dB below background in order to comply with the assurances overall. In summary, this contract strategy provided headroom and flexibility to cater for any potential cumulative effects detected at the noise interfacing stage.

The IP D25 design stage studies resulted in background noise reports, which set out the LA90,T dB levels that had been jointly established with the relevant local authorities. Preliminary noise assessment reports were produced, based upon the agreed background levels. The results of these studies were formally issued to the relevant local authorities in the form of IP D25 ‘Preliminary Assessment Findings’ reports in 2013 and were included in the contract Works Information.

In terms of the IP D25 design-phase reporting by the station, shaft and portal contractors, this was split into two stages in order to allow reasonable endeavours judgements to be made by the Client organisation at an appropriate point in the programme. In practical terms, contractors whose MEP designs were predicted to be unable to achieve -10dB were required to produce an IP D25 Noise Options/Justification Report setting out their reasonable endeavours and the limitations on any further noise control measures. If such limitations were accepted this led to an agreement on an alternative noise criterion. In all cases, the predicted noise levels of the contractors’ final designs are documented in IP D25 Noise Demonstration Reports.

The Specifications were written so as to try and remove any ambiguity from the fixed noise assurances. For example, the assurances use the terms ‘normal operation’, ‘under all reasonably foreseeable circumstances’ and ‘with additional allowances made for calculation uncertainty’ which required definition for the purposes of the contract.

In the cases of ‘normal operation’ and what was ‘reasonably foreseeable’ the Specifications required that all modes should be considered with the exception of emergency operations. As regards ‘uncertainty’, the Specifications standardised this to +3dB. However, in view of the complex factors involved in determining this allowance and the differing ways in which various acoustic consultants engaged on Crossrail chose to manage uncertainty, in the final analysis it was decided to leave this to the professional judgement of the individual acousticians, provided that some additional allowance was included that could be evaluated and justified.

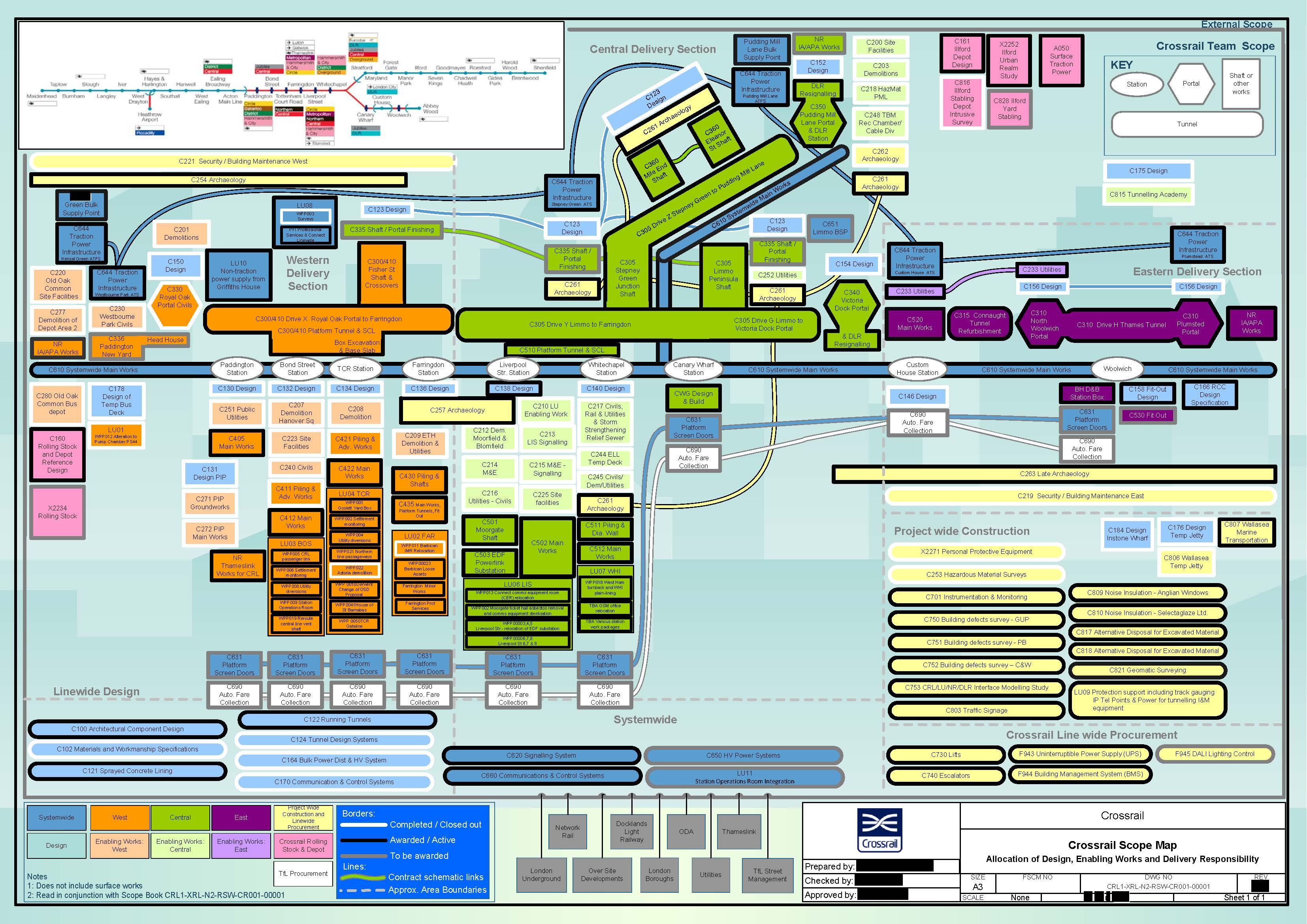

Consideration of Acoustic Interfaces

The nature of the contracting strategy whereby numerous designers, contractors and partner organisations were involved in delivering the project created added complexity in terms of defining the technical interfaces and contractual boundaries (refer to Fig. 2 below).

Figure 2: Crossrail Scope Map

For a technically transverse discipline such as acoustics, this was particularly challenging.

For example, the noise at the receptors associated with the tunnel ventilation system was found to be influenced by the design of both the mechanical systems (e.g. fans, attenuators, dampers, etc.) and the stations/shafts’ architecture (e.g. civil structure) and building elements (i.e. linings, louvres, doors/hatches, etc.). This required very detailed acoustic interfacing and a high level of collaboration between the various contractors and their designers/acousticians. Generally, this challenge was managed through noise interface workshops attended by all the relevant designers and specialists.

In cases, such as the above example, where complex acoustic design interdependencies existed between interfacing contractors, at a given Crossrail development (e.g. a central station), the relevant acoustic data was managed through the adoption of Give & Get Reports, which were exchanged between interfacing contractors’ noise & vibration specialists to maintain/track an agreed common understanding of the various noise contributions and their cumulative summation. An example ‘Give and Get’ report from Paddington Station [9] is provided in Appendix 5 for reference. This report set out the agreed noise mitigation measures together with input data regarding the operation of the fans and noise levels generated within the tunnel ventilation shafts for the range of normal operational modes. The Give & Get spreadsheet (Appendix A) also provides the various noise contributions at the receptors and their totality relative to the relevant background noise levels.

Noise Testing & Commissioning (T&C)

As part of their IP D25[3] Noise Demonstration Report submission, the contractors were required to include a T&C methodology outlining how compliance with the assurance requirement to “complete the standard suite of acceptance tests required for such plant” would be demonstrated. Generally, this was based upon the guidance given in BS4142:1997[4] and BS7445-1:2003[6]. Where noise measurements were proposed it was found that in most cases the receptor noise levels arising from the fixed installations’ operation were anticipated to be well below the prevailing background noise levels, and that direct measurement at the receptor locations would not, therefore, provide a reliable evaluation of the fixed plant noise contribution. In such cases, Clause 6.3.5 of BS4142:1997[4] was referenced, whereby the specific noise level is determined by a combination of measurement and calculation.

The combination of measurements and calculations greatly increased the complexity of the T&C exercise and reporting. Firstly, in many cases multiple contractors needed to carry out IP D25 [3] T&C surveys at a given Crossrail development, in accordance with their individual scopes . This meant that all the significant noise source contributions had to be identified and evaluated at locations in close proximity to the Crossrail development (e.g. Sound Pressure Levels at 1.0m from outlets), together with the sound propagation transfer functions to the various receptors.

In many cases the N&V consultancy appointed by the contractors to undertake the T&C noise surveying was not the same company that undertook the acoustic design. This may be viewed as a benefit in terms of independence, although results in inefficiencies in terms of relearning the design.

Lessons Learned

Evaluation of Background Noise Levels

Early discussions with the local authorities through the Crossrail EHO Sub-group – Fixed Noise Source Working Group would have avoided some initial disagreement and led to a quicker definition being established.

Organisational Structure

Although not part of the original organisational arrangement on Crossrail, it was found advantageous to bring acoustic engineers into Crossrail’s Chief Engineers Group (CEG) mid-way through the project, to provide support on the integrated design of the stations, shafts and portals, particularly in relation to the building / architectural acoustics which were not governed by the fixed installation noise assurances and to address the interface with the oversite development.

The split of acoustic accountabilities between two different departments in the same Directorate (CEG – building noise and Sustainability & Consents – environmental noise) created an added interface in what was already a complex design issue. This was managed by ensuring that the acoustic specialists in both departments collaborated closely when matrix working with the Delivery Directorate, but inevitably created a less efficient process than could otherwise have been achieved.

Recommendations for Future Projects

The overarching discipline that the fixed installation noise assurances fall within is that of acoustics. Hence, the management processes that need to be adopted to deliver them concern the acoustic design of a whole development. This is a critical distinction, as noise itself is the by-product (i.e. unwanted sound) of a potentially very complex set of physical interactions. This starts as the mechanical sound or vibration sources and ends as human perception at receptors. All the various transmission paths between these sources and receptors have to be considered and evaluated. Acoustics is, therefore, a high-level transverse design consideration that cannot be implemented as an independent parallel process to the rest of the design. Where there is a single designer for the whole development this is relatively straightforward to achieve. However, where multiple contractors are responsible for different design elements within a single structure the challenge is much more complex. This fact points to the need for a holistic acoustic strategy to be formulated at the commencement of a project and particularly so for projects such as railways where multiple contracts deliverables have to be integrated within a single development. This strategy should then be tracked throughout the design phases, procurement, installation and finally to testing & commissioning.

Acoustic design integration needs to be considered from the outset and maintained through to completion. In particular, it should be considered that an integrated acoustic design is capable of addressing the noise and vibration requirement s both within a development (e.g. Noise Ratings, reverberation control, speech intelligibility/privacy, etc.) and externally (e.g. environmental noise levels in the public realm and at residential and commercial receptors).

Taking the above strategy as the starting point the following recommendations are made for future infrastructure projects with complex noise requirements split across multiple contractors such is likely for new rail projects. Ensure that the Acoustic Strategy:

- Recognises that acoustics is an overarching transverse discipline, inseparable from the developments’ designs.

- By definition, transverse equates to a large number of design interdependencies and technical interfaces, leading to increased complexity in their management which need capture in and managed through Interface Plans.

- Position all acoustic management in the engineering design team with responsibility for both internal and external acoustic performance.

- Ensure acoustic design risks are included in risk registers from the outset.

- Where commitments given during the authorisation process result in the need to define certain terms for the later purposes of design establish early on suitable working groups with the beneficiaries of those commitments to define them.

- Use auralisation tools, to convey the subjective effect of noise target setting and noise mitigation measures for the purpose of acquiring informed stakeholder understanding.

- For the purposes of learning legacy consider establishing long-term academic collaboration(s) aimed at extracting and analysing relevant information on an entirely independent basis to produce assessments and recommendations for the benefit of future projects. For example, to perform an analysis of the acoustic calculation methodologies and models used on the project and conduct advanced vibroacoustic measurements on sub-systems and elements of the developments, in order to refine these methodologies and models. Such feedback loops should lead to the development more cost effective design tools/processes and better optimised noise control solutions.

- In the significantly longer term, consideration as to how artificial intelligence could be harnessed to provide factual oversight of transverse disciplines, such as acoustic, to automatically detect relevant design issues, conflicting design requirements and compliance risks, as part of the Technical Assurance process.

References

[1] Register of Undertakings & Assurances – Latest version of the Crossrail register of U&As, as published in August 2011

[2] Crossrail Learning Legacy, Management of Undertakings & Assurances, Iftikhar Abutin, August 2018.

[3] Crossrail Limited. Crossrail Information Paper D25 – Noise from Fixed Installations. Approved – Version 3 – 23/04/08.

[4] The British Standards Institution. BS4142:1997 Method for Rating Industrial Noise Affecting Mixed Residential and Industrial Areas. Status: Revised/Withdrawn. ISBN: 0 580 28300 3.

[5] The British Standards Institution. BS4142:2014 – Methods for Rating and Assessing Industrial and Commercial Sound. Status: Current. ISBN: 978 0 580 80051 1.

[6] The British Standards Institution. BS7445-1:2003 – Description and Measurement of Environmental Noise. Guide to Quantities and Procedures. Status: Current. ISBN: 0 580 43032 4.

[7] Crossrail ‘Method for Establishing Background Noise Levels for Fixed Installation Assessments’. Crossrail EHO Sub-group – Fixed Noise Source Working Group.

[8] Crossrail Central Section Project Requirement Specification – ‘Noise from Fixed Installations for Deep-Level Stations (Crossrail Information Paper D25)’.

[ 9] ATC/C610 Systemwide Main Works. ‘TVS – Acoustics “Give and Get” Information Spreadsheet – Paddington Station’.

-

Document Links

-

Authors

Steven Sheridan CEng - Crossrail Ltd

Steven is a Chartered Engineer with over 20 years’ experience as a technical specialist engaged in acoustics, noise & vibration both in industry and consultancy. He has held team leadership roles over the last 10 years both internationally and in the UK in connection with the railway industry and environment & sustainability and was an Expert advisor to the European Commission on acoustics R&D. Steven has been with the Crossrail project in the CRL Technical Directorate since2010, overseeing operational and construction noise & vibration.

Specialties: Acoustics, noise & vibration, railway N&V rolling stock and infrastructure, construction site N&V, underground railway tunnel ventilation noise, fixed plant and building services noise control, environmental assessment (EIA/ES), planning & noise, railway R&D, transportation, sustainability, BREEAM, EfW, wind energy, architectural and building services.