Crossrail approach to Contract Completion – The Employer’s Completion Process

Document

type: Technical Paper

Author:

Piotr Swieboda CEng MICE

Publication

Date: 05/05/2023

-

Abstract

This report discusses the approach taken by the Crossrail programme to ensure due diligence before certifying construction contracts as complete under the NEC contract. The Employer’s Completion Process (ECP) was introduced to define all essential checks necessary to achieve completion based on the Works Information, eliminating ambiguity associated with completion requirements.

The report explains the route to contract completion and the issuance of a defects certificate and their relationship with the ECP. The ECP involved various checks assigned to different lead functions within Crossrail, ensuring a high level of assurance. The report highlights that the dispensation for ECP outstanding items was provided in instances where items remained open for an extended period or fell outside of the contractor’s scope. The process was applied to both Whole Contract Completion and Sectional Completions, with the latter being tailored as necessary. The ECP process was typically initiated six months before the planned contract completion to ensure sufficient time for all necessary checks.

-

Read the full document

1 Introduction and Context

The NEC form of contract was used in the construction of the Elizabeth Line, as explained in detail in the Learning Legacy paper ‘Crossrail approach to NEC’ [1]. 46 main construction contracts were awarded to Tier 1 contractors and certified as complete under the NEC contract.

This paper explains the approach taken to introduce balance checks at the Crossrail programme to ensure sufficient due diligence before certifying contracts to contractors as complete under the NEC terms of the contract.

Completion is a contractual term defined in the NEC contract under Clause 11.2, which states that ‘Completion is achieved when the Contractor has done all the work specified in the Works Information by the Completion Date and corrected notified Defects that would have prevented the Employer from using the works and Others from doing their work.’

To provide full clarity on the requirements for Completion, the Crossrail project, similarly to the approach taken by the Channel Tunnel Rail Link project in the past, introduced the Employer’s Completion Process (ECP). By defining all the essential checks necessary to achieve Completion based on the Works Information, the ECP eliminated the ambiguity associated with terms such as ‘partial completion,’ ‘staged completion,’ and ‘substantial completion,’ which are not part of the NEC contract.

It is worth mentioning that the achievement of completion for individual contracts did not constitute the final certification. It marked the start of the defect liability period, which typically lasted for 52 weeks. After the defect liability period had passed, the contractor was issued with a defect certificate, which was the last certificate confirming the close-out of the contract.

2 Employer’s Completion Process explained

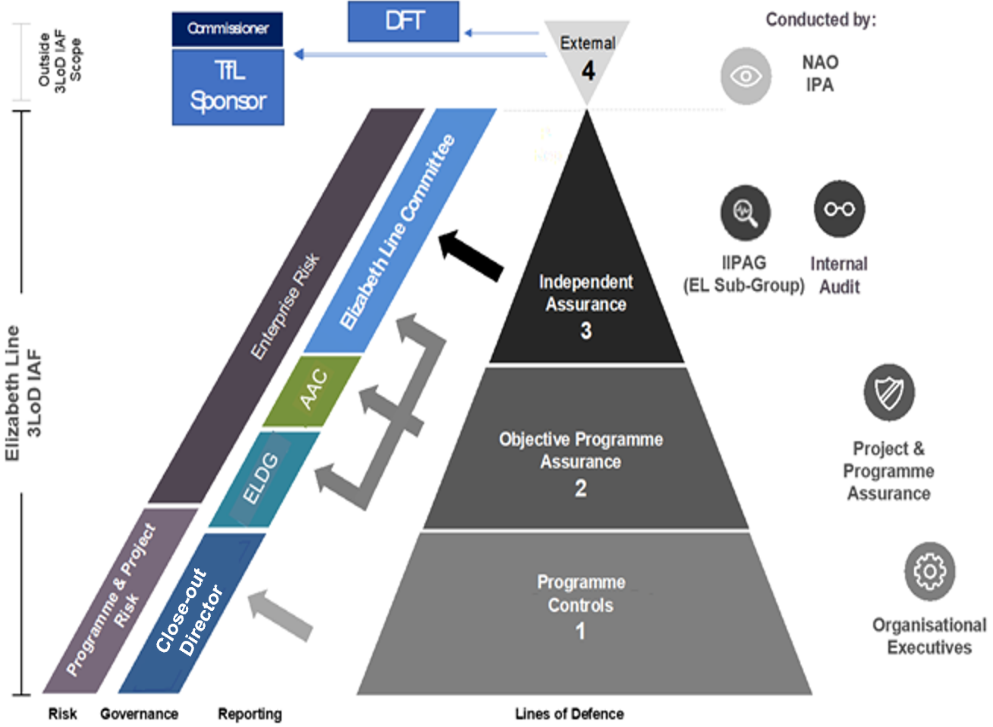

The Employer’s Completion Process is one of the key processes within the ‘Three Lines of Defence’ Integrated Assurance Framework (3LoD IAF) which applies to all activities relating to the Elizabeth Line Programme. The 3LoD IAF provides integrity and compliance for programme delivery, each line of defence is independent, incrementally building assurance evidence. The ECP is a key process in demonstrating assurance in the First line of Delivery (LoD1). See below and 3 LoD model (diagram)

- First Line (LoD 1) – Programme Delivery Controls covering both Crossrail and Rail for London (Elizabeth Line) organisations. These functions are embedded into day-to-day management of the organisations each overseen by the relevant Director. This includes the ECP.

- Second Line (LoD 2) – Project and Programme Assurance (PPA) coordinates and integrates across all of Crossrail’s and RfL (EL) assurance using a risk-based approach to assess and report on confidence in delivery, adequacy of assurance and potential threats (risks) to objectives.

- Third Line (LoD 3) – TfL Internal Audit and a subgroup of the Independent Investment Programme Advisory Group (IIPAG) provide an independent assessment of the overarching integrity and performance of Crossrail’s 3LoD IAF conducting independent risk-based internal audits and reviews as necessary.

Figure 1 Crossrail ‘Three lines of Defence’ Integrated Assurance framework 3LoD

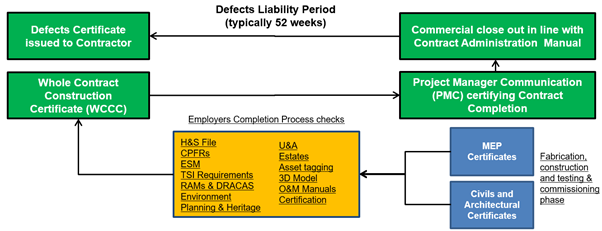

2.1 Route to contract completion and defects certificate

The below section provides more details on the phases leading to contract completion and issuance of the defects certificate and their relationship with the Employer’s Completion Process.

Figure 2 – Route to contract completion and defect certificate

A presentation showing the ECP process is included as a supporting document[2].

2.1.1 Fabrication, construction and testing & commissioning phase

During this phase of the works, the contractor had to identify a Package Breakdown Structure, which was to be submitted and accepted by the Crossrail Project Manager. These certification packages consisted of appropriate records (defined in the Inspection and Test Plans, or ITPs) that provided progressive assurance for the works constructed.

2.1.2 Employer’s Completion Process checks

The Employer’s Completion Process (ECP) was the Crossrail process that demonstrated that Crossrail Limited (CRL) had exercised due diligence in a responsible manner by verifying that all necessary legal and contractual obligations were fulfilled before accepting and closing out the Tier 1 construction contracts. This process ultimately authorised the CRL Project Manager to certify the contacts as complete under the NEC3 Contract.

The ECP process was applied to both Whole Contract Completion and Sectional Completions. In the case of Sectional Completions, the process was tailored as necessary.

Completion Type ECP Process Whole Contract Completion Standard ECP process as defined in the Employers Completion Process Procedure and the Contract Administration Manual Sectional Completion Tailored ECP process that is based on the standard process and tailored to the requirements of the specific Sectional Completion Verification of the legal and contractual obligations was demonstrated by the sign-off of Contract Closeout Checklists for each Contract. These Checklists contained a series of questions generated by each CRL Function for their respective sign-off. The questions were framed to seek evidence to demonstrate that all requirements within their respective functional responsibility have been addressed. This ensured that accountability for acceptance of the completed Works was consistently maintained. Checklists were produced for sign-off by the following functions:

Requirements for Contract Closeout Checklists review and sign off by Functional Leads Contract Closeout Checklist Function CRL Functional Lead

Completion of the whole of the worksSectional Completion C1 Health & Safety CRL H&S Head of Assurance Required Required C2 Technical Compliance CRL Chief Engineer supported by HoDs Required At discretion of

Functional LeadC3 Planning, Heritage and Highways CRL Head of Sustainability & Consents Required At discretion of

Functional LeadC4 Environment CRL Head of Sustainability & Consents Required At discretion of

Functional LeadC5 Undertakings & Assurances CRL Head of Sustainability & Consents Required At discretion of

Functional LeadC6 Land and Property CRL Head of Estates Required At discretion of

Functional LeadC7 Rail Interfaces (LUL, DLR, NR, LO) CRL Rail Interface Manager / Engineer / Project Manager / Care & Custody Manager

Required At discretion of

Functional LeadC8 Systemwide (interfaces with civil contracts) – applicable to initial contract only Interface Manager Required At discretion of

Functional LeadC9 Technical Information CRL Chief Engineer Required At discretion of

Functional LeadC10 Third Party Agreements CRL Head of Agreements Required At discretion of

Functional LeadC20 Completion CRL Completion Manager Required Required C30 Authorisation to Accept WCCC or SCCC CRL Completion Manager Required Required The ECP process was defined in detail in the Employers Completion Process Procedure[3], and the Contract Administration Manual[4].

As can be seen above the ECP process involved several checks that were assigned to various lead functions within Crossrail. It is essential to emphasize that these checks were performed independently, outside of the Crossrail delivery team, thereby ensuring a high level of assurance.

The ECP process was typically initiated 6 months prior to the planned contract completion in order to ensure sufficient time for all the checks necessary. The start of the process was recorded during the kick-off meeting which was followed by weekly meetings during which the detailed requirements were discussed and actions assigned. The main checks contained within the Employer’s Completion Process were as follows:

ECP Form and WI ref. Area of main checks Acceptance by C1 – Health and Safety (requirements Works Information Vol 2B – Parts 17 and 19.6)

Checking completeness and standard of the Health & Safety Files (H&S Files). Checking discharge of control points in line with the Crossrail CDM Management procedure.

Project H&S Advisor and

Head of H&S

C2 – Technical Compliance (requirements WI Vol 2B – Parts 7, 13, 22 and 32 Stations, Shafts & Portals and Parts 29 and 32 Systemwide)

Check design acceptance for permanent works carried out by the contractor. Final Design Statement FDS(b) should be submitted and accepted by Crossrail. Crossrail Programme Functional Requirements (CPFR). The Crossrail programme functional requirements refer to the set of specifications and features that the Crossrail project had to meet in order to achieve its intended functions and objectives. These requirements were established to ensure that the Crossrail programme met the needs of all stakeholders and delivered the desired outcomes. Design and Construction – check evidence in DOORS database.

Engineering Safety Management (ESM). The engineering safety management system of Crossrail aimed to ensure that all aspects of the project were designed, constructed, and operated in a safe and efficient manner. Checking contractors’ deliverables (e.g. ESJ – Engineering Safety Justification); checking CRL deliverables (e.g. SJ – Safety Justification)

Interoperability Regulations (The Technical Specifications for Interoperability (TSIs) are a set of technical standards and requirements. The TSI interoperability requirements include specifications and technical solutions that ensure that railway infrastructure, rolling stock, and systems from different manufacturers and operators can work together seamlessly. Checking plan in place to deliver Technical Standards for Interoperability (TSI).

Gate Impact Reports. Checking that changes to the approved design have been properly assessed and accepted in relevant Gate Impact Reports.

RAM (Reliability, Availability, Maintainability) demonstration process and the Data Recording and Corrective Action System (DRACAS). Check DRACAS records in the system and track close outs. Check submissions of RAMs documentation by contractor.

Check on close out of the CRL observations raised, check on close out of open non-conformances

Check on completeness of Verification Activities carried out on site

Check on completeness of red-line drawings and as-builts

Check that the final Consolidated Outstanding Works List (Defects List) has been accepted by the Chief Engineer

Check that the cyber security information provided by contractor was accepted by Crossrail.

Engineering Manager

Requirements Manager

Head of System and Interoperability

Head of System and Interoperability

Engineering Manager

RAMS and DRACAS Manager

Supervisor’s Representative

Chief Engineering Group – Head of relevant Discipline

Chief Engineer or delegate

Chief Security Officer

Final acceptance for the entire form Chief Engineer

C3 – Planning, Heritage & Highways (requirements WI Vol 2B – Part 3)

Check if conditions in Planning & Heritage and Highway Consents have been fully discharged and complied with. Head of Sustainability & Consents C4 – Environment (requirements WI Vol 2B – Parts 6, 17 and 21)

Check on environment reporting data; Site waste management plans; Survey information; Contaminated land; Maintenance regime; CARs, NCRs, Environmental incident investigations; Environmental design; Archaeological information; Boreholes; BREEAM & CEEQUAL. Head of Sustainability & Consents C5 – Undertakings and Assurances (requirements WI Vol 2B – Part 4)

Check if all applicable Undertakings & Assurances have been discharged and handed over in line with the Commitments Compliance Plan. Head of Sustainability & Consents C6 – Land and Property (requirements Crossrail Estates Management Plan and procedures).

Check on site/land handovers and records maintenance. Head of Estates C7 – Rail Interfaces (requirements Crossrail Project Delivery Plan and procedures).

Check on open interfaces with other stakeholders i.e. LUL, NR, DLR, LO. Project Manager responsible for the interfaces C8 – Routeway interfaces with civil contracts. Applicable to initial contract only. (requirements Crossrail Project Delivery Plan and procedures).

Check on interfaces and open issues between civils and routeway contracts prior to site handover. Project Manager responsible for the interfaces C9 – Technical Information Document Quality & Control

(requirements WI Vol 2B – Parts 20 and 13 and 14 Stations, Shafts & Portals and Parts 20 and 29 Systemwide)

Asset data and labelling

(requirements WI Vol 2B – Part 13.5 Stations, Shafts & Portals and Pt 29.2.10 Routeway)

3D Models/As Builts

(requirements WI Vol 2B – Parts 7 and 13)

O&M manuals

(requirements WI Vol 2B – Part 7)

Check on documents maintenance and acceptance in the Electronic Database Management (EDM) system eB.. Code 1 or 4 documents, Obsolete / Cancelled documents, Drawing deliverables (including DD%), Deliverables on MDL (eB structure), Records in order (Metadata), O&M deliverables vs O&M DocControl User Guide, IM Training deliverables. Check if the asset data provided by the contractor has been accepted by the Infrastructure Manager without comments and all outstanding works closed out.

Check if as built 3D model and associated as built drawings have been accepted and meet CAD related standards.

Check if all the O&M deliverables and manuals submitted by the contractor have been accepted and is all the information available on eB (EDM system).

Doc Control and Data Compliance Manager Asset Information Provision Manager

Head of CAD Delivery and Support

Handover Information Manager

C10 – Third Party Requirements (requirements defined in the relevant contracts)

Check that all the third party agreements (TPAs) that relate to the contract have been identified and are deemed discharged. Head of Agreements C20 – Completion Defects & Nonconformances

(requirements WI Vol 2B – Part 20)

Certification of Works

(requirements WI Vol 2B – Parts 20 and 13.3 Stations, Shafts & Portals and Parts 20 and 29.2 Routeway)

Technical Training for Infrastructure Managers

(requirements WI Vol 2A – Part 1 Stations, Shafts & Portals and

WI Vol 2A Pt 21 Routeway)

Check that all open NCRs have been closed out or agreed and accepted to be added to the Defects List. Check that the all the Work Breakdown Packages have been completed and signed off.

Check if the contractor has delivered all training for Infrastructure Managers in accordance with the agreed Training and Strategy Plan.

Supervisor’s Representative Certification Manager

Training Manager

C30 – Authorisation to accept Whole /Sectional Contract Construction Certificate Check that all the ECP checks have been diligently completed and signed off. Authorise to the Project Manager acceptance of the WCCC to the contractor. Completion Manager Confirmation of the above checks is demonstrated by the sign-off of the C1-C30 Contract Closeout check sheets for each Contract. These check sheets contain a series of questions generated by each CRL Function for their respective sign-off. The questions are framed to seek evidence to demonstrate that all requirements within their respective functional responsibility have been addressed. This ensures that accountability for acceptance of the completed Works is consistently maintained. Checklists are produced for sign-off for the above disciplines. After review and sign off by Functional Leads, the final works acceptance is by the CRL Project Manager (PM). The checklists are available as a supporting document to this paper[5].

Dispensation for ECP outstanding items

In instances where the ECP items remained open for extensive period of time due to pending third party acceptance or fell outside of contractor’s scope and at the same time all contractors’ deliverables had been accepted by CRL delivery team or agreed to be added to the Defects List, the Programme Director might have decided to provide a dispensation for these ECP items.

The dispensation and the relevant justification were to be recorded on the Dispensation Form[6]. The Dispensation Form was be filled in by the CRL delivery team providing enough information to the Programme Director to decide on the dispensation.

2.1.3 Whole Contract Construction Certificate (WCCC)

The Whole Contract Construction Certificate (WCCC) was a certificate provided by the contractor at the end of the contract, confirming that the works had been constructed in accordance with the accepted design and the Works Information (WI) requirements. The WCCC was also referencing the defects list which, in the opinion of the contractor, was acceptable to satisfy the NEC Completion.

Following the submission of the WCCC, it had to be accepted by the NEC Supervisor’s Representative on site providing the proposed defect list was seen as minor, and the certification packages and WI requirements were satisfactorily delivered by the contractor.

To provide a second line of defence against premature certification of the works by the delivery team, the WCCC was also to be accepted by the programme NEC Supervisor, who, in consultation with the NEC Supervisor’s Representative on site and the Completion Manager, had to ensure that all ECP checks were satisfied, and the ECP completion process was closed out.

2.1.4 Project Manager Communication (PMC) certifying Contract Completion

Once the programme NEC Supervisor signed the WCCC[7], the Project Manager, who was in receipt of the ECP C30 form confirming ECP close-out, was authorised to sign off the WCCC and issue the Project Manager Communication to the contractor, stating in line with the Contract Administration Manual that:

“In accordance with Clause 30.2 the certified date of Completion for the Contract is xxx. The defects date is 52* weeks after the date of Completion of xxx. The uncorrected defects at Completion are set out within the attached Whole Contract Construction Certificate reference xxx”

2.1.5 Commercial close out of contracts

After completing the contract, the Project Manager had to prepare the Contract Completion Commercial Report. This report had to be submitted to the Executive Sub-committee for approval. The process of preparing the commercial close-out report has been described in more detail in the Contract Administration Manual[4].

2.1.6 Defects Certificate

At the end of the defects liability period, the NEC Supervisor had to issue the Defects Certificate[9] to the contractor, confirming that all defects identified were corrected or that the uncorrected defects were listed on the certificate for commercial resolution. Once the Defects Certificate was issued, it triggered the final assessment of the amount due and the issue of a payment certificate by the Project Manager. This assessment usually took 8 weeks after the Supervisor issuance of the Defects Certificate.

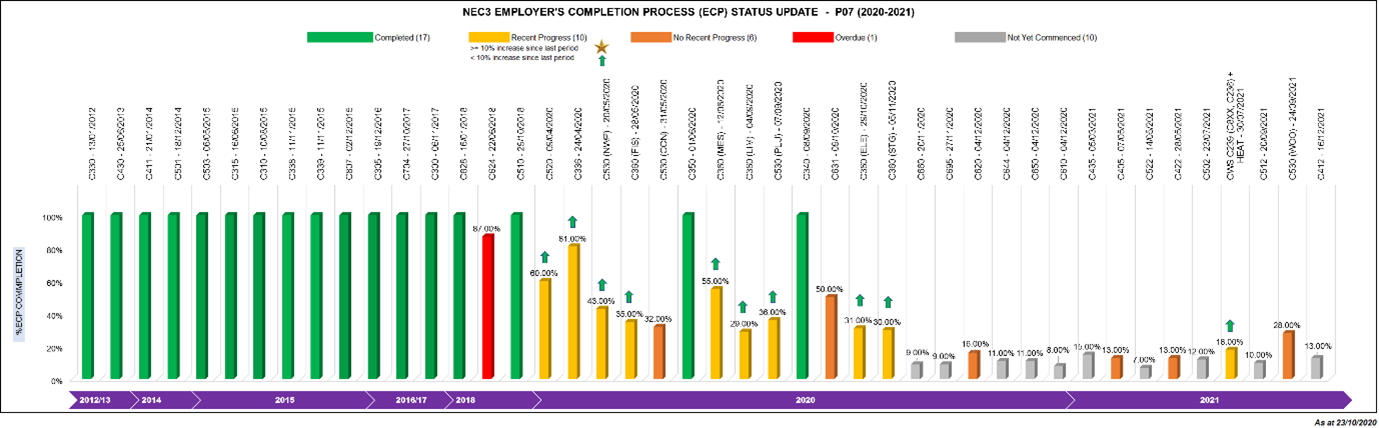

2.2 Resources involved in ECP signoffs

In order to ensure the successful completion and sign-off of every section of the ECP, 35 functional specialists with expertise in their respective areas were engaged to provide their independent sign-off. This was done separately from the delivery team. The contractor provided evidence of the ECP sign-offs to the CRL delivery site team. Once the team was satisfied with the evidence, they were requesting final sign-off from the Functional/Discipline Heads at CRL. These heads then provided the final check sheet sign-off. This process ensured that every section of the ECP was thoroughly reviewed and approved by subject matter experts, contributing to the quality of the overall project deliverables.

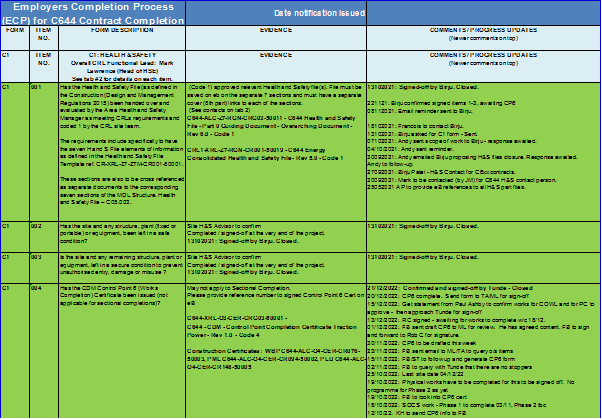

Figure 3 – Employer’s Completion Process individual sign offs2.3 ECP tracker and CRAF assessments

2.3.1 ECP tracker

To facilitate the management of the ECP process for individual contracts, an ECP Tracker was developed and implemented on Sharepoint. This tool allowed for collaborative work on necessary evidence and progress tracking. The ECP Tracker contained all the checks listed on the individual check sheets, along with the typical evidence required to satisfy each check. By using this tool, the project team could easily track the progress of the ECP and ensure that all necessary evidence was gathered and available for review. Below is a sample of the ECP Tracker:

Figure 4 – Sample of the ECP tracker

The ECP Tracker played a crucial role in ensuring that the ECP process was efficiently managed and that all necessary evidence was readily available for review. It enabled the project team to stay on top of the progress of individual contracts and make any necessary adjustments to ensure timely completion.

The full ECP tracker can be found below as a supporting document[9].

2.3.2 CRAF Assessments

In 2018 the Crossrail quality department introduced CRAF performance assessments to enhance the progress of ECP on different contracts. These assessments were conducted by independent assessors who were experts in their respective fields and were not directly involved in the work being assessed. The assessors reviewed the work against a set of predetermined criteria to ensure that it met the required completion standards, providing contractors with feedback and identifying areas for improvement.

In addition to ensuring that the work met completion requirements defined within the ECP process, CRAFs helped raise the profile of the ECP process across the programme. By providing contractors with clear expectations and requirements for completion, the ECP process became an integral part of the overall programme management framework.

To further promote healthy competition and raise the profile of the ECP process, a league table was established that ranked contractors based on their CRAF scores. This provided a tangible incentive for contractors to strive for excellence and continuously improve their work.

Overall, the introduction of CRAFs was a success for the Crossrail programme. It provided a structured and comprehensive approach to assessing the quality of work being carried out by contractors and helped to ensure that the necessary requirements for achievement of completion were met.

3 Lessons learned

Challenges

The implementation of the ECP process came with its fair share of challenges, including:

- Considerable scope of physical works remaining (e.g., on the surface/urban realm, etc.) meant that works were not complete, which did not allow for Environment / Undertakings & Assurances / Consents sign off within ECP. To address this issue, the project teams had to ensure they focus on the entire scope of the contract, including the surface/urban realm works.

- Initially, the ECP process was not seen as a priority by Project Management until after handover of site was achieved. To address this issue, a series of programme-wide briefings and completion readiness assessments were arranged to increase awareness and raise the profile of the completion process.

- Contractors not providing acceptable assurance documentation and claiming achievement of completion based on documentation submission rather than CRL/RFL acceptance. To address the issue the project teams implemented a more rigorous process for reviewing and verifying the documentation. This included providing sufficient notice to the contractors about the required documentation and conducting more thorough checks to ensure that all necessary evidence of completion had been provided before Crossrail acceptance.

- Project Managers not following the ECP process and signing off Whole Contract Construction Certificate and certifying completion via Project Manager Communication (PMC). To address the issue programme-wide briefings were carried out to ensure that all project managers were fully aware of their responsibilities and the steps involved in the ECP process.

- Transition of teams to other parts of the organization created challenges for the ECP sign-off process. For instance, the Estates and Assets Teams moved to Rail for London, and Infrastructure Manager Training packages transferred to HSE. To address the issue the ECP process was regularly reviewed to accommodate changes in team structures and responsibilities. By doing so, the ECP process could adapt to the changes and maintain its effectiveness.

- Issued Project Manager Instructions (PMIs) requiring additional work on site or assurance documentation.

- Maintaining consistency of sign-off requirements for functional leads/subject matter experts within their teams. This issue was resolved by the ECP team implementing a clear and standardised sign-off process. This included defining the roles and responsibilities of functional leads/subject matter experts within their teams, as well as establishing clear and consistent criteria for sign-off requirements.

Successes

There were several successes in the ECP process, including:

- The ECP process helped to identify and rectify issues early on, reducing the likelihood of delays. This was achieved by ensuring that all necessary documentation and sign-offs were in place before the completion of each contract.

- The ECP process was effective in promoting transparency and accountability, as key functional leads were required to provide sign-off for their respective areas of expertise. This helped to prevent any misunderstandings or disagreements during the project delivery and completion phase.

- The ECP process facilitated collaboration and communication between different teams and departments, ensuring that everyone was working towards a common goal. This improved the efficiency and effectiveness of the project delivery.

- The successful implementation of the ECP process helped to build confidence and trust among stakeholders.

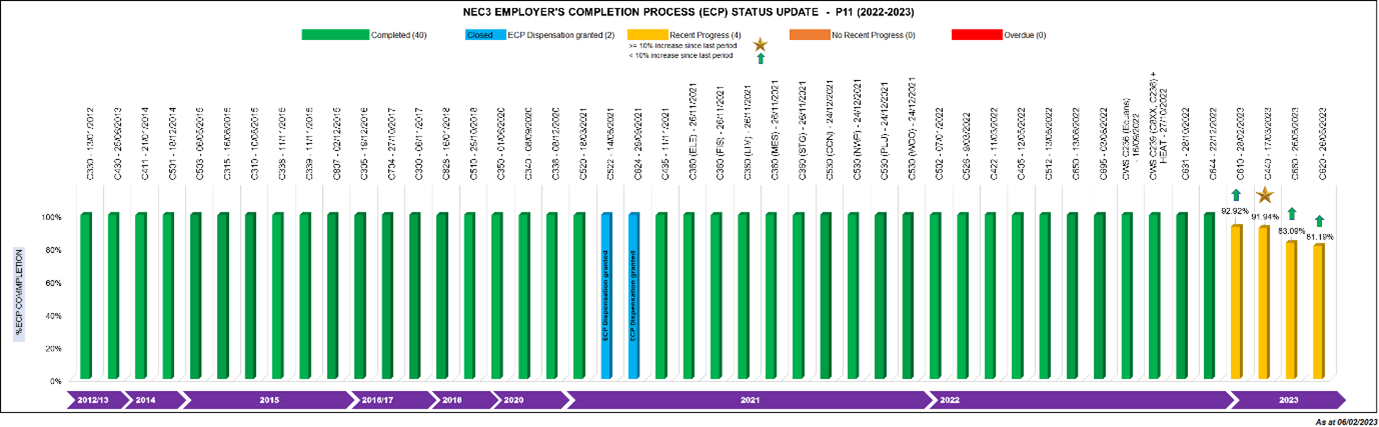

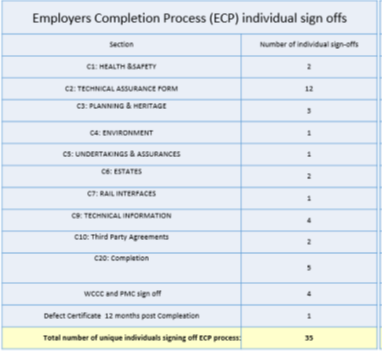

- Fine-tuning the process allowed improved progress to be made, as shown in the figures below:

2019/20 Period 7 – 46 ECP Contracts / 19 Closed (41%)

2022/23 Period 11 – 46 ECP Contracts / 42 Closed (91%)

Figure 5 – ECP Progress update – as at 06/02/2023 (P11) – 91% closed

Figure 6 – ECP Progress update – as at 23/10/2020 (P07) – 41 % closed

- Excellent reporting metrics were developed[10].

- Buy-in and support for the ECP at the highest level allowed the profile of the ECP to be raised. This helped to drive the success of the ECP across the program.

4 Conclusion

The ECP process was successfully completed for over 46 contracts throughout the Crossrail programme. The challenges faced during the implementation of the process were addressed through various reviews, which rationalised the process in line with program changes. The reviews concluded that the ECP process was absolutely vital in closing out contracts in a controlled and responsible manner, ensuring that the required assurance documentation needed to support any future investigations or discovered defects was available in an orderly and transparent fashion.

As quoted by the programme director, “It helps me sleep at night and gives a warm feeling that everything was closed in a formal and transparent matter.”

5 Acknowledgements

I extend my sincere gratitude to the work colleagues who generously provided their expertise and assistance in the preparation of this paper. Special thanks to Aram Stirzaker, Chris Titterton, and Johnson Monteiro for their valuable contributions. I would also like to acknowledge the feedback received from the reviewers, Lee-John Allen and Elias Sahyoun.

6 References

[1] Megan Hands, David Morrice (2018) Crossrail Approach to NEC

[2] ECP Presentation

[3] Employers Completion Process Procedure

[4] Contract Administration Manual (CAM)

[5] Employers Completion Process Contract Close Out Checklists (‘C’ Forms)

-

Document Links

-

Authors

Piotr Swieboda CEng MICE

Piotr Swieboda was the Completion Manager on the Crossrail programme, where he played a pivotal role in developing an effective framework for the Employer’s Completion Process. This involved creating and implementing processes, systems and tools to manage contract closeouts for the programme. Piotr is a Chartered Engineer (CEng MICE) and a member of the Association of Project Managers (APM). He has worked on numerous complex projects as both a client and contractor, including the Kings Cross Station Redevelopment and Thameslink Programme, such as the refurbishment of Blackfriars Bridge. He is also a mentor for the Association of Polish Engineers in Great Britain.

https://www.linkedin.com/in/piotr-swieboda-ceng-mice-455b0720/