The Railway Integration Approach at Crossrail

Document

type: Technical Paper

Author:

Jeremy Bates MEng CEng MBA, Jonathan Morris MEng

Publication

Date: 02/08/2018

-

Abstract

Crossrail poses significant integration challenges due to the complex nature of the scheme. This document provides an overview of the approach employed at Crossrail to define the various dimensions of “Railway Integration” and a high level summary of the processes and techniques used to manage them. It will be useful to major project organisations that have multiple parties and complex technical interfaces to manage.

-

Read the full document

Background

The Crossrail Programme poses significant challenges when it comes to integrating the various systems that make up the end-to-end railway and the organisations responsible for delivering them, due to the complex nature of the scheme. These include:

- Connecting a metro-style central section service with a suburban rail service on the Great Eastern and Great Western surface sections.

- Ensuring seamless operation across three different signalling systems; Train Protection Warning System (TPWS) on the Great Eastern, European Train Control System (ETCS) on the Great Western, and Cab-based Train Control (CBTC) in the central section.

- Managing the scale of the project with multiple new underground stations, tunnels, rail systems, rolling stock and surface section upgrades being delivered in many separate contracts; this requires meticulous attention toward the management of the interfaces between the various parties.

- Introducing a new infrastructure manager (Rail for London) for the central section routeway and a new operator (MTR Crossrail) who have to work in partnership with existing infrastructure managers (IMs), such as Network Rail and London Underground.

This document provides an overview of the approach employed at Crossrail to define the various dimensions of “Railway Integration”; it includes a high level summary of the processes and techniques used to manage them and a summary of the lessons learned that may be of benefit to future similar schemes.

Objectives of Railway Integration

Successful Railway Integration has been defined at Crossrail Limited (CRL), in conjunction with the Programme Director and CEO, as being satisfied if the following outcomes are achieved:

- Passenger service is state of the art, and amongst the best railways in the world

- The end to end railway is ready for revenue service operations on time

- Functional and physical interfaces perform as the design intended

- Testing and commissioning activity has demonstrated that the railway meets functional, performance and RAM requirements

The railway is deemed officially ready to transport passengers when:

- The Office of Rail and Road (ORR) and EU certification process is complete

- The Operator and Maintainer have all the required assurance evidence and asset management information together with operational information systems

Definition of “Integration”

Integration can be thought of in many ways – this document will cover all aspects of railway integration at CRL and define how each piece is managed, and who is accountable.

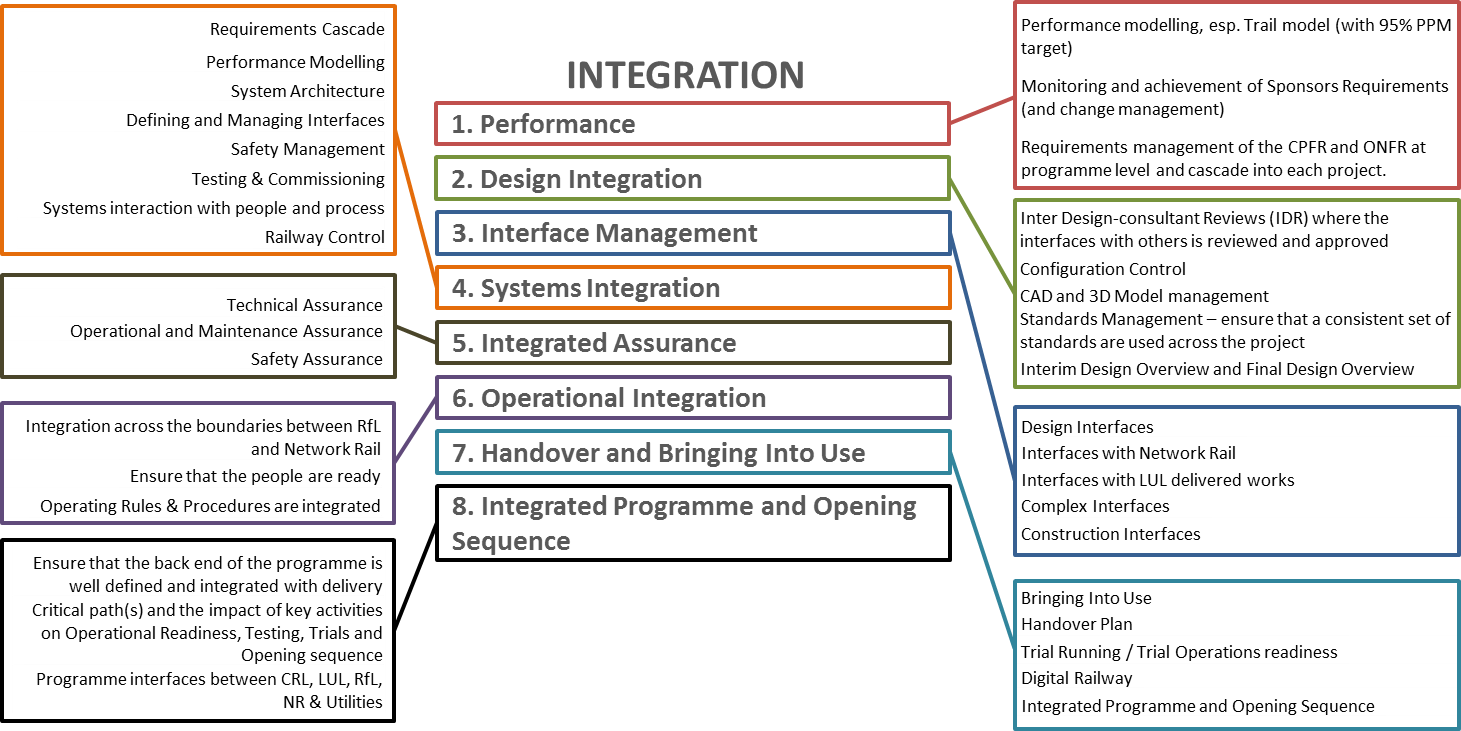

An overview of CRL’s approach to Integration is shown in the diagram below:

Figure 1 – Integration at Crossrail

Integration Categories

The focus on integration at Crossrail is on the overall (collective) performance of the railway, not on its individual component parts. This focus is organised around the “4 pillars”: Collectively Performs; Collectively Safe; Collectively Operable; Collectively Maintainable.

The constituent parts of each of the 8 integration categories are illustrated below and described in more detail in the subsequent sections.

Figure 2 –Integration categories

1 Performance

Crossrail has the ambition to be a “World Class Railway” and hence the management of the passenger experience and achievement of the Sponsors Requirements is key and achieved by:

- Demonstrating achievement of a 95% Public Performance Measure (PPM) target using performance modelling, especially through using Network Rail’s TRAIL software

- Monitoring achievement of Sponsors’ Requirements (and ensuring ongoing change management over any new or changed requirements)

- Management of the Crossrail Programme Functional Requirements (CPFR) and On Network Functional Requirements (ONFR) at programme level, and cascading these into each project

2 Design Integration

The Design Management Process (owned by the Chief Engineer) defines how CRL manages design integration. The integration of individual designs into the overall project is managed by CRL who act as the main co-ordinators for design control, integration and the acceptability of the end product. CRL has the responsibility to ensure individual outputs are fully integrated to enable delivery of a complete railway. Hence CRL is responsible for managing integration at a programme level for the Central Section Works, Network Rail (NR), London Underground (LU), Docklands Light Railway (DLR), Rolling Stock and Depot, and Surface Works.

Key aspects of the Design Process that ensure the designs are (and remain) integrated are:

- Inter Design-consultant Reviews (IDR) where the interfaces with others are reviewed and approved

- Configuration Control (i.e. important reference designs that impact others are change managed and, when new versions are published, all affected parties are informed)

- CAD and 3D Model management

- Standards Management – ensuring that a consistent set of standards are used across the project

- Interim Design Overview (IDO) and Final Design Overview (FDO) where the collective designs from each contract for a particular Element (e.g. Station) are reviewed together.

3 Interface Management

Design Interfaces

The CRL Interface Management Procedure and Interface Control Template manage the interfaces between the rail systems and the civil and M&E works to confirm that adequate space-proofing and access requirements have been defined and agreed between the interfacing parties. The interfaces between Systemwide contractors and third parties (such as NR or LU) are specified in the works information for each Design & Build contract. The contractors in turn describe their interface management processes, Interface Requirements Specification (IRS) for each system- to-system interface in the Design Management Plans subject to review and acceptance through Systemwide. For more complex interfaces, the contractors produce Detailed Interface Requirements (DIR).

The owner of the Interface Management Process is the Head of Integration, who tracks status of interfaces across the programme (in terms of overall definition and critical “complex” interfaces) and escalates issues as required.

It is the responsibility of each of the project teams to manage their interfaces with others and resolve issues as they arise.

Interfaces with Network Rail

These interfaces are defined in the same way as any others, through ICDs and DIRs. The CRL Surface Team manage the overall co-ordination of these interfaces; however, each contract’s interfaces remain the responsibility of the Project Manager within the Delivery organisation.

Interfaces with London Underground delivered works

Stations Operations Rooms are one of the critical interfaces within each of the five LU stations. This is managed through the London Underground Crossrail Team (LUCT), who employ the AIDD (”Agreed Interface Definition Document”) process to define the interfaces with the CRL projects. These AIDDs are essentially the same as an ICD.

Complex Interfaces

There are a number of interfaces (“high complexity”) which require an additional integration effort:

- To ensure that the contract-to-contract designs align and are consistent across boundaries with other projects (e.g. NR surface works)

- To ensure that areas where multiple contract-to-contract interfaces exist are managed as a single entity and that the assumptions, scope, designs and programmes are aligned.

These are managed by assigning a lead project manager of one of the interfacing contracts who has overall responsible for the success of the complex interface.

Construction Interfaces

The Construction Interface Management Procedure describes the process of interface management undertaken by the Tier 1 Contractor and those responsible for the design and construction, to ensure that it is carried out in a planned, consistent and beneficial manner. It also details the roles and responsibilities of the Delivery Team and Contractor for carrying out the interface management during the lifecycle of the project.

Once the Contractor has identified all the construction interfaces from the available sources, they should produce an Interface Management Plan (IMP). The IMP should include interfaces to all the systems, sub-systems, components and any other interfaces that relate to the scope of the contract, including all civil and infrastructure elements.

4 Systems Integration

Systems Integration covers a significant proportion of the overall integration effort, and is managed through the Systems Integration Management Plan. In CRL, systems integration is defined as:

- Requirements cascade

- Performance modelling

- System architecture

- Defining and managing interfaces

- Safety management (and integration)

- Testing & Commissioning

- Systems interaction with people and process

- Railway control

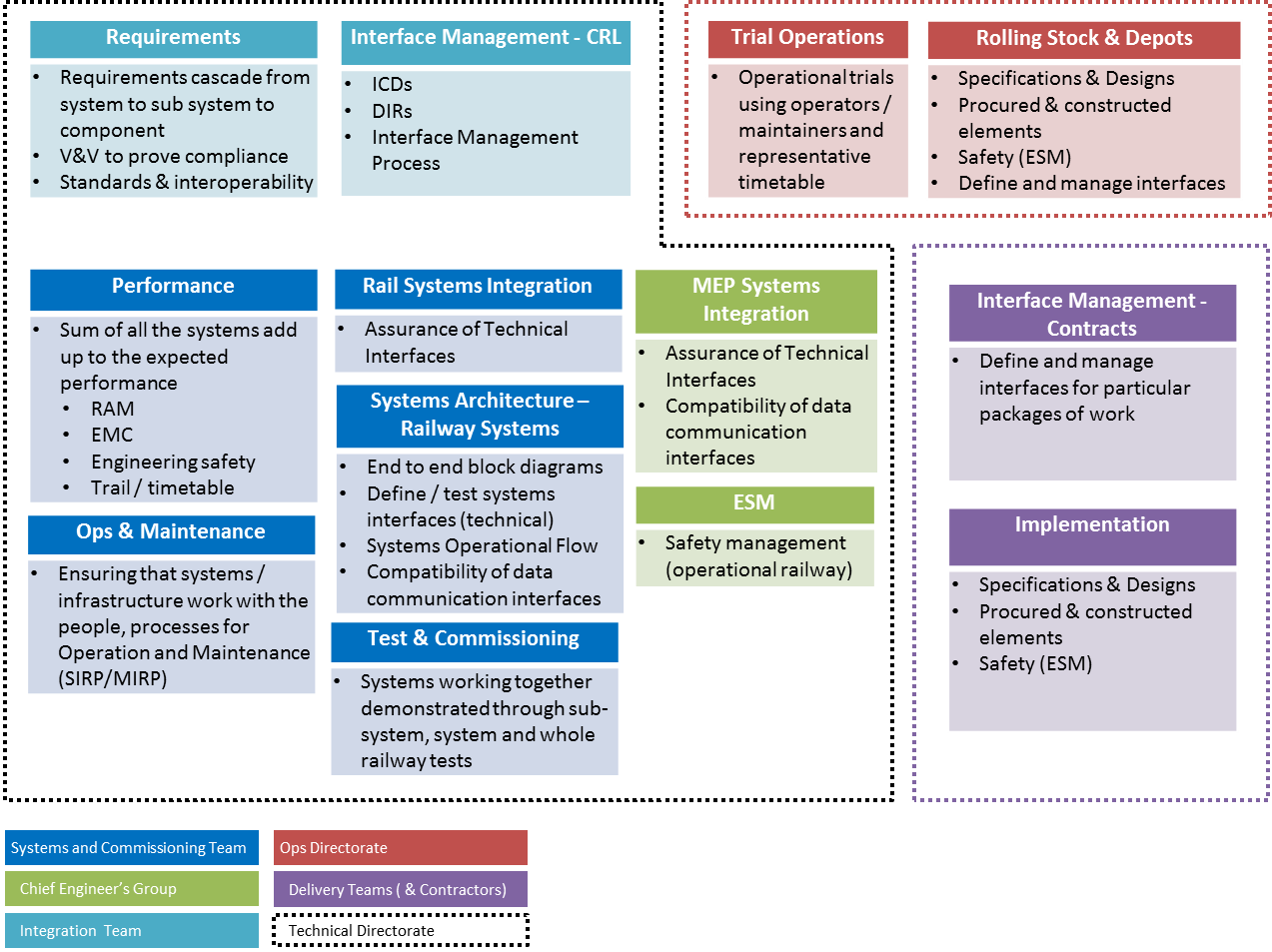

The distribution of the systems integration activities in the CRL organisation is illustrated in the diagram below:

Figure 3 – Systems integration activities

5 Integrated Assurance

In order to handover the railway successfully, CRL needs to provide the appropriate assurance evidence to the IMs and Operators. This will need to cover the “4 pillars”: Performance, Operations, Maintenance and Safety.

The following Integration activities contribute to the overall demonstration of assurance:

Table 1 – Integration Activities to satisfy the “4 pillars”

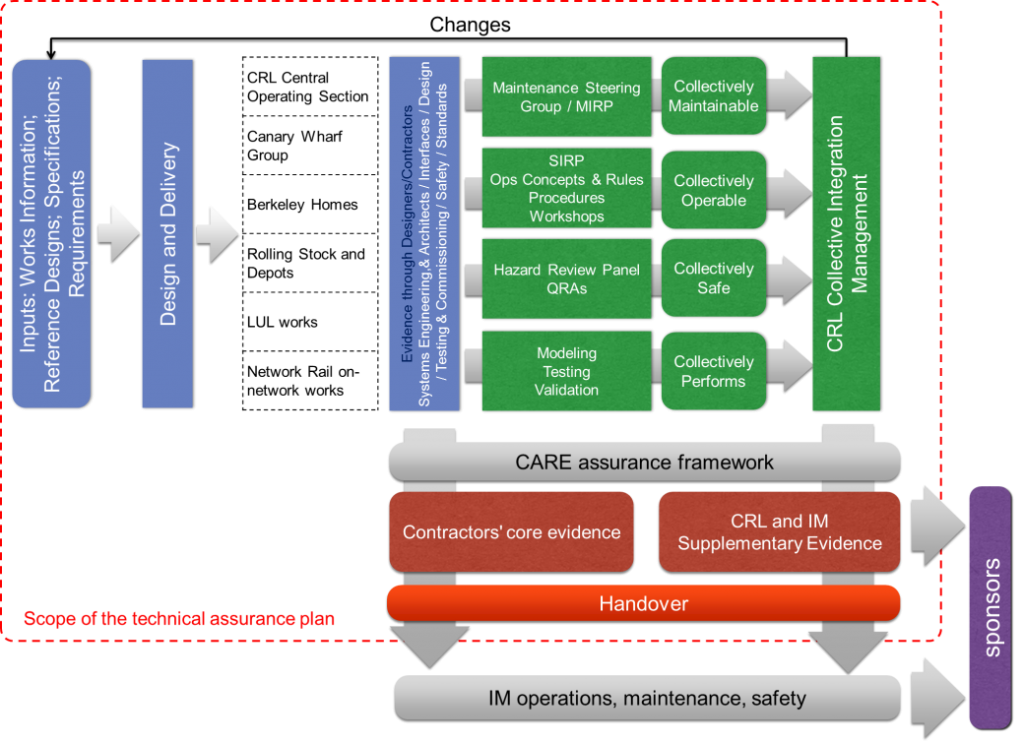

Integration Activity Performance Operations Maintenance Safety Collectively Safe Hazard management process X Design and Engineering safety justifications (DESJs and ESJs) X Focussed Quantified Risk Assessments X Interoperability: Technical Standards for Interoperability (TSI) compliance (NoBo) and Notified National Technical rules (NNTRs) X Common Safety Method (CSM) compliance – AsBo reports X Interface Hazard Analyses X Safety Justifications (per Element) X Overall end to end railway safety justification (one line-wide) X Collectively Operable System Integration Review Panel (SIRP) Outputs X CPFR requirements compliance X X X Collectively Maintainable Maintenance Integration Review Panel (MIRP) Outputs X Maintenance boundaries X X Maintenance Plan (per station and system) X RAM analysis X X X Collectively Performs Simulation / modelling X Test & Commissioning certificates (integration, dynamic testing, trial running) X Technical Assurance Design Assurance outputs X X X X Architectural assurance X Materials Compliance X X Requirements Management X X X X EMC Management X X IDO and FDO reviews X X X X Progressive Assurance (inspections) X Test & Commissioning certificates (integration, dynamic testing, trial running) X Figure 4 – Scope of the Technical Assurance Plan (TAP)

Managing Assurance Deliverables

The CARE (Crossrail Assurance Reporting Environment) system supports the collation and demonstration of design and construction evidence, apposite to the eventual Elements by which Crossrail will hand over the railway to the IMs. The packages of assurance evidence will follow the agreed System Breakdown Structure in determining the totality of assurance evidence required for each asset, managed within the overarching framework of the Technical Assurance Plan (TAP).

6 Operational Integration

Integration across the boundaries between RfL and Network Rail

The ORR has stated that a lead organisation should be accountable to ensure that the end to end railway is safe. ORR considers that this should be a Duty Holder – i.e. not CRL. It has been agreed that the lead organisation will be RfL, as RfL/TfL corporate has responsibility for the Crossrail Train Operating Company (CTOC), Rolling Stock, Old Oak Common Depot and is the Central Operating Section Infrastructure Manager (IM).

This integration role will manage the following:

- The overall co-ordination of the hazard transfer process between IMs along the route

- Project management of the consultation process with Network Rail and LUL as the “bringer of change”

- Collation of the evidence that this integration has taken place, in order to present to the ORR

Ensure that the people are ready

- Managing the familiarisation, induction and training to ensure that these activities are aligned with and support the CRL test and commissioning plan

- Ensure that recruitment supports the training requirements, for both the initial “train the trainer” sessions (delivered by CRL) and the larger “train the workforce” activities to support Operational Readiness and Opening.

Operating Rules & Procedures are integrated

Ensure that the Rulebook and associated procedures are aligned with the infrastructure that CRL are delivering, and manage the hazards that have been transferred from CRL to the Operators. This is partly managed through the MIRP and SIRP process and Hazard Review Panel.

7 Handover and Bringing Into Use

Crossrail recognises that the process for receiving the completed assets from contractors and handing them over to the final owner/operator needs to be managed very carefully and can often be an aspect of project delivery that is not given sufficient attention. This is addressed through a number of activities:

Handover Plan

- Implementing a single agreed methodology and plan for handover (s) to the IMs of the Elements of the railway and development of the associated programme. Early definition of the deliverables, expectations and programme for Handover with both the projects and the IMs is key to avoiding a bow-wave of documentation and evidence gathering at the end of the project.

Trial Running / Trial Operations readiness

- Ensuring that the CRL testing and commissioning teams, and the RfL, LUL and NR Operations and Maintenance teams, are ready to run the railway (trials etc.)

- Sufficient resources are available (drivers, station staff etc.)

- Personnel are trained, ready for operational readiness activities

- Required Elements are confirmed available and ready for use

Bringing Into Use

- Ensuring that CRL meet the requirements of the Regulators in bringing the railway into use

- Ensuring that the Operators meet the requirements of the Regulators in bringing the railway into use

- Ensuring that the Operators are ready to accept Crossrail and bring the railway into use

Digital Railway

- Ensuring we handover a set of asset information / digital data to maximise benefits (“smart infrastructure”)

- Working with the IMs to help them develop their internal asset management and maintenance/operational control systems to maximise the opportunities associated with the Digital Railway

Operational Readiness

- Overall Operational Readiness status is managed through the Operational Readiness Steering Group which brings together all interested parties across CRL, RfL, LUL and NR. This is managed by the RfL Operations Director.

8 Integrated Programme and Opening Sequence

- Ensuring that the back end of the programme is well defined and integrated with Delivery

- Ensuring a full understanding of the critical path(s) and the impact of key activities on Operational Readiness, Testing, Trials and Opening sequence

- Ensuring programme interfaces between CRL, LUL, RfL, NR, Utilities are well understood and managed

Governance

Railway Integration Authority (RIA)

The role of the Railway Integration Authority, established by the Programme Director to oversee railway integration programme-wide, is to ensure that the rail systems, rolling stock and infrastructure combined with operations and maintenance requirements deliver a safe operational railway that meets Sponsors’ Requirements. It focusses on five key points:

- Managing the key integration risks – driven largely by the risk register giving adequate focus on areas outside of the central section, and making recommendations & decisions.

- Reviewing Technical integration issues – it is important to provide a forum where Crossrail can review and discuss key technical issues which impact overall Railway Integration.

- Knowledge sharing – provide a place where important concepts, processes, and progress can be shared with the wider Crossrail team.

- Integration Programme- increasing the understanding of the programme, working back from the Bringing Into Use / Handover process and enabling greater visibility of current progress and impact on integration activities

- Running the Railway Integration Review Process (RIRP) to provide a measure of integration progress.

The RIA’s remit is to review railway integration issues which may take the form of engineering, operational/maintenance or programme/phasing integration issues. The RIA assesses their impact and makes decisions as to the best way forward, thereafter monitoring progress to a successful conclusion. In achieving this aim the RIA mobilises teams from time to time to investigate particular issues and derive a solution.

The RIA is constituted of competent engineering and management leads, operators and maintainers to ensure that decisions have the support of all affected parties. The RIA is also supported by Interface Working Groups focussed on the detailed review and management of the interfaces with Network Rail.

The RIA does not act as a technical assurance body that receives and review technical assurance submissions, which will be managed in accordance with the Technical Assurance Plan, though it can support the needs of assurance by identifying resolution routes for issues.

Railway Integration Review Points (RIRPs)

RIRP reviews are carried out across all work streams to provide evidence that:

- The key integration risks are adequately managed

- The works will deliver the current Employer’s Requirements baseline

- The works take account of the current Operations Concepts baseline

- The works have reached a defined Standard of development

- The interfaces between the various works are aligned

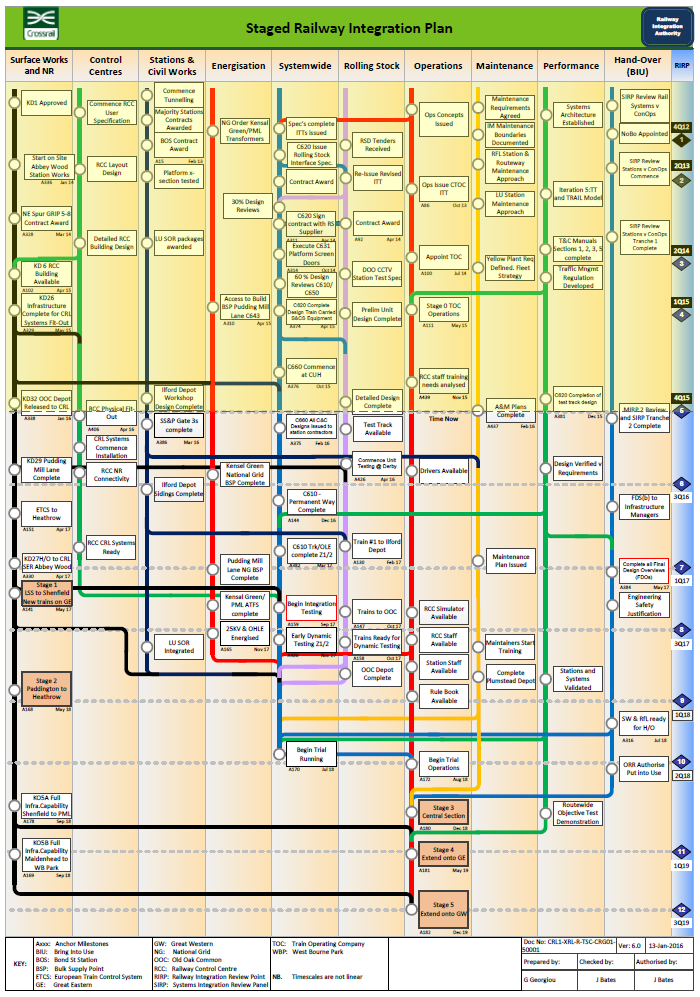

The Railway Integration Review Points are not “stop/go” gates. The aim is to review the status of the programme and identify integration risks, not to stop progress. The RIRP dates are shown in the table below:

Table 2 – Railway Integration Review Point (RIRP) plan for Crossrail

RIRP # Timing Headline Focus RIRP 1 Q4 2012 Systemwide ITTs Issued and RIA processes in place RIRP 2 Q2 2013 All Stations and Systemwide Contracts Awarded RIRP 3 Q2 2014 30% System Design Reviews Complete and Rolling Stock selected. RIRP 4 Q1 2015 Readiness for initial handover to Systemwide ( installation begins) and CTOC readiness for Stage 0. 60% System Design Reviews Complete RIRP 5 Q4 2015 Systemwide 90% Design Gates substantially complete; Commence FDO (Final Design Overview) reviews; Detailed train design complete RIRP 6 Q3 2016 Gate 3 design complete – all stations and systems (excl C620). Train testing commenced RIRP 7 Q1 2017 Stage 1 Readiness, C610 permanent way complete RIRP 8 Q3 2017 Stage 3 Readiness for Integration Testing RIRP 9 Q1 2018 Stage 2 Readiness and Stage 3 Readiness for Dynamic Testing RIRP 10 Q2 2018 Stage 3 Readiness for Trial Running and Handover RIRP 11 Q1 2019 Stage 4 Readiness: Passenger Service extended to Great Eastern RIRP 12 Q3 2019 Stage 5 Readiness: Passenger Service extended to Great Western Figure 5 – Staged Railway Integration Plan

Meeting Structure

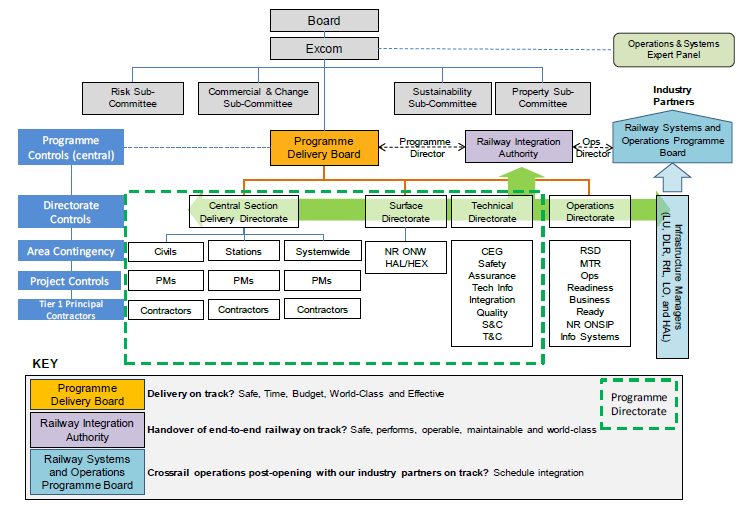

There are multiple meetings across the programme that contribute to the overall objective of Integration as detailed in the diagram below:

Figure 6 – Crossrail Governance Map

Crossrail’s governance is used to control the management of CRL to achieve its objective of delivering an integrated end-to-end railway. It applies to all meetings identified as necessary to deliver the Crossrail Project. It is owned by the Programme Director and reviewed at least every six months, or whenever an organisational change occurs.

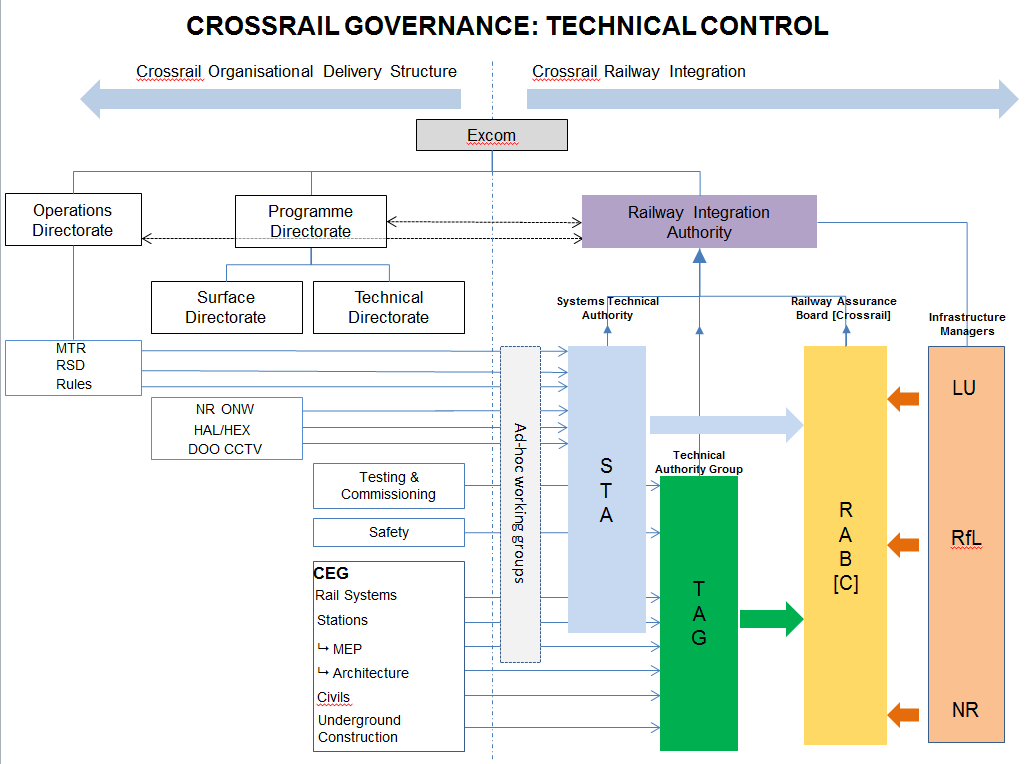

Figure 7 – Crossrail Governance: Technical Control

Lessons learned for future projects

There are a multitude of lessons from Crossrail’s integration approach that would be of benefit to future projects:

Define what Integration means

- Define what is meant by integration – there are many layers of integration

- Establish an overall integration plan as early as possibly in the process

- It’s not just systems integration – it’s wider than that

- Consider a RIRP process to look across whole programme

Be clear on your requirements

- CRL managed via CPFR and ONFR ( a specific subset of CPFR for Network Rail)

- NR follow the process well but it has been quite difficult to manage the NR outputs to feed into the wider CPFR process. Different databases where a single common database could have been used

- Include Operational Concepts and Safety Requirements into the overall Requirements Management process, and track compliance

- Single database for CRL central section (DOORS) works well

- Be careful to define “looser” requirements – e.g.

- “whole life costs” – exactly what does that mean?

- “Remote condition monitoring” – precisely of what?

Watch your interfaces

- Crossrail managed interfaces with Interface Control Documents (ICDs) – a good process in principle, but difficult to nail down in practice

- Be careful of the interface ‘conditions’ – lots of interfaces have been defined and “code 1” approved, but still containing multiple open issues, which can remain hidden

- Rail systems and stations need to be at the same level of design at the same time in order to effectively manage the interfaces

- Specific leads are needed to manage the complex interfaces and cut through the contractual boundaries to understand the whole

Keep focus on Systems Integration

- Recognise that including “systems integration” in the contract does not guarantee it is done.

- Don’t forget the challenges of delivering new signalling systems – such as the European Train Control System – and its interfaces at the transitions

- Include a Crossrail Integration Facility (CIF) in the plan from the beginning to test software release interfaces and configurations

- Embed a systems architecture into design and recognise it as a controlled document (i.e. actively manage it through the design process and keep up to date)

- Try to synchronise the Rail Systems, MEP and Civils designs so that they’re all progressing at the same time

- Consider that the Contractors’ ability to manage design and keep 3D models up-to-date and integrated with others is usually limited

Plan Technical Assurance and embed the plan

- Crossrail’s Technical Assurance Plan (TAP) was useful in defining all the key assurance processes, and how design was to be reviewed through the gates process

- Think about how to hold contractors to dates for design completion. This has been very difficult with Crossrail contracts, as they weren’t clearly embedded

- Consider partner organisations – it has been difficult to align NR deliverables to the CRL deliverables and this made life complicated on South East Spur, where NR work needed to integrate into a larger “railway systems” element. Document names, asset listings, processes were all different.

Lead the Safety Case from the top-down

- Establish railway-level hazard model first

- Derive safety requirements from this

- Capture these safety requirements in appropriate “strategic engineering justifications” – this will ensure that technical decisions at a strategic level are aligned to clearly demonstrate mitigation of the key hazards

- Cascade to contractors using a requirements management tool – e.g. a Project Wide Hazard Register (PWHR) – this works really well

- Think about how to prove the integrated safety justifications up-front for stations, shafts and rail systems – otherwise with the result is lots of separate contract-based documents that can’t be proven to work as a whole. Crossrail addressed this by creating safety justifications (as the client) to join up

- At the interfaces with NR we are creating “interface safety justifications” that draw upon safety evidence from both NR and CRL in order to prove safe integration. These are again produced by the client team, not contractors (albeit, Siemens have produced a interface specific safety case for the signalling over the fringes)

Integrate the Operational and Maintenance Requirements

- Use Operations Concepts – these have been invaluable

- SIRP and MIRP process has worked really well to drive out the integrated performance of the assets and check alignment to Operations and Maintenance Concepts

- Set a high level Reliability, Availability and Maintainability (RAM) target and cascade to all contractors and partners – CRL have found it hard to align NR and CRL RAM portions to give a whole answer when dependent on NR to deliver at a given time

- Think about wider maintenance and depot strategy, and avoid redeveloping “live” assets in operational use

Get your Governance right

- Client and Sponsorship arrangements are key to achieving successful railway integration

- At Crossrail, the RIA (Railway Integration Authority) provided a focal point with the RIRP process giving a formal method for assessing status

- Complex Interfaces require more attention – dedicated leads are needed, and involve the Operators early

- Recognise Integration in risk allocation

- Put in place a formal process for scope gap identification and fixing

Glossary

AIDD Agreed Interface Definition Document CARE Crossrail Assurance Reporting Environment CBTC Communication Based Train Control CPFR Crossrail Programme Functional Requirements D&B Design and Build DLR Docklands Light Railway EMC Electro Magnetic Compatibility ETCS European Train Control System FDO Final Design Overview IDO Interim Design Overview IDR Inter Design-consultant Reviews IMs Infrastructure Managers LU London Underground LUCT London Underground Crossrail team M&E Mechanical and Electrical MIRP Maintenance Integration Review Panel NR Network Rail ONFR On Networks Functional Requirements ORR Office of Road and Rail PPM Public Performance Measure RAM Reliability, Availability, Maintainability RIA Railway Integration Authority RIDC Rail Innovation and Development Centre RIRP Railway Integration Review Process RSD Rolling Stock and Depot SIRP Systems Integration Review Panel TPWS Train Protection & Warning System V&V Verification and Validation -

Document Links

-

Authors

Jeremy Bates MEng CEng MBA - Crossrail Ltd

Jeremy Bates is the Head of Integration at Crossrail. He is accountable for assuring that a safe, operable, maintainable end-to-end railway is delivered that performs to the Sponsors Requirements. Prior to Crossrail, Jeremy was Director of the integration programme at Balfour Beatty and head of the programme management office at BAA.

Jonathan Morris MEng - Crossrail Ltd

Jonathan Morris is the Programme Integration Manager at Crossrail. He is responsible for ensuring the integration of the end-to-end railway operates within a clear programme governance structure, and assuring that critical integration issues that support testing and commissioning and handover are identified and resolved in a consistent strategy across the Crossrail organisation. Jonathan started his career in project management in airports and subsequently moved into programme advisory. He now specialises in programme governance, strategic planning, and performance management on major complex programmes where he brings over 13 years experience to bear. He has been with Crossrail since February 2014.